-2-

090908_Instructions for use RTCS Base- and Wok-Line_E.doc

CONTENT

1General remarks................................................................................................................3

1.1Description of danger signs...........................................................................................3

1.2Purpose of induction cookers ........................................................................................4

2Description of products.....................................................................................................5

2.1Scope of supply .............................................................................................................5

2.2Products.........................................................................................................................5

2.3RTCS Base-Line/Wok-Line units at a glance...............................................................6

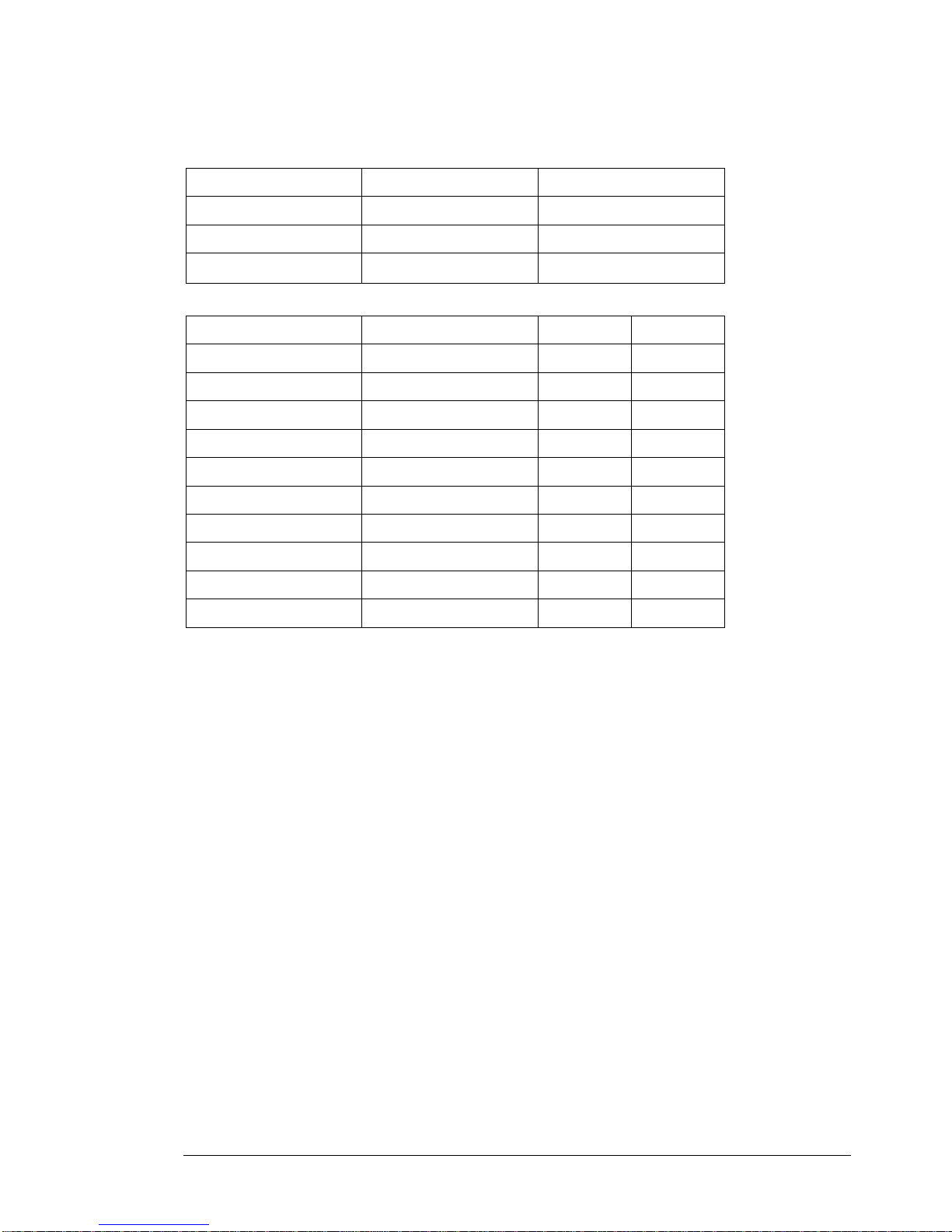

2.4Technical Data...............................................................................................................8

3Installation..........................................................................................................................9

3.1Scope of supply .............................................................................................................9

3.2Requirements of installation..........................................................................................9

3.3Definition of interfaces..................................................................................................9

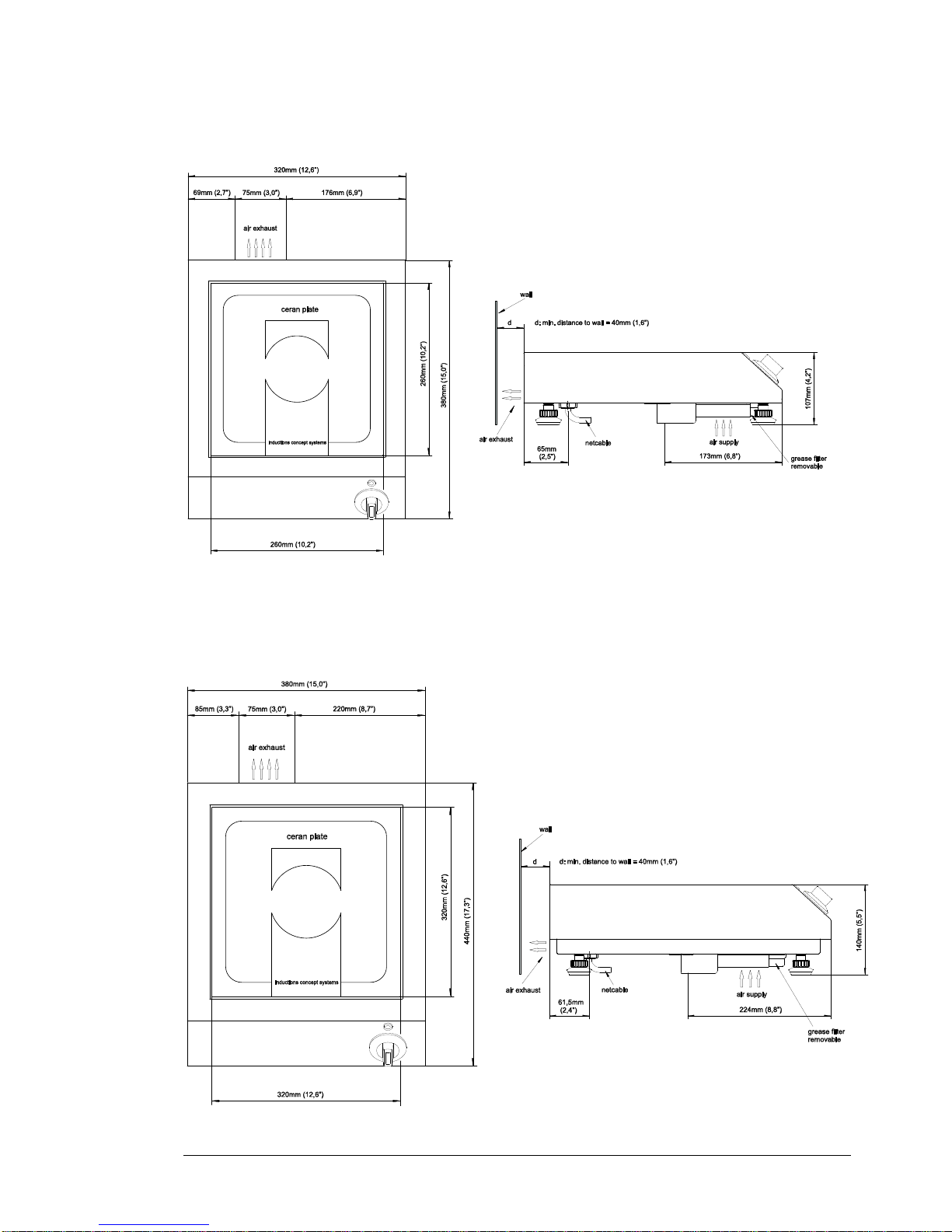

3.4One cooking point unit BH/BA 1500, BH/BA 1800, BH/BA 2500, BH/BA 3000 and

BH/BA 3500................................................................................................................10

3.5One cooking point unit SH/BA 3500 and SH/BA 5000..............................................10

3.6SH/WO 3500, SH/WO 5000 and SH/WO 8000..........................................................11

3.7Installation...................................................................................................................11

4Operation test...................................................................................................................12

5Operation..........................................................................................................................13

5.1Cooking process ..........................................................................................................13

5.2Comfort........................................................................................................................13

6Safety instructions ...........................................................................................................14

6.1Risk in the event of non-observance of the safety information...................................14

6.2Safety conscious work.................................................................................................14

6.3Safety information for the operator/operating personnel ............................................14

6.4Improper operating methods........................................................................................15

6.5Unauthorized reconstruction and use of spare parts....................................................15

6.6Pan detection ...............................................................................................................15

6.7Control of the heating area..........................................................................................15

7Out of operation...............................................................................................................16

8Fault finding/Rectification..............................................................................................17

8.1Fault finding with error code.......................................................................................17

8.2Fault finding without error code..................................................................................18

9Cleaning............................................................................................................................20

10Support .............................................................................................................................21

11Waste disposal concept....................................................................................................22