Service-Manual, new version author: Chr. Fuchs 17.06.99 / INDUCS Ltd. 18.09.03 page 6of 28

On the power board, a main filter for the interference suppression is integrated

Certifications

Satisfies the latest specifications: VDE EN 60335-1/-2/36, UL 197; CAN/CSA/C 22.2 No.

109, SSF 4-1996, CE-compliant.

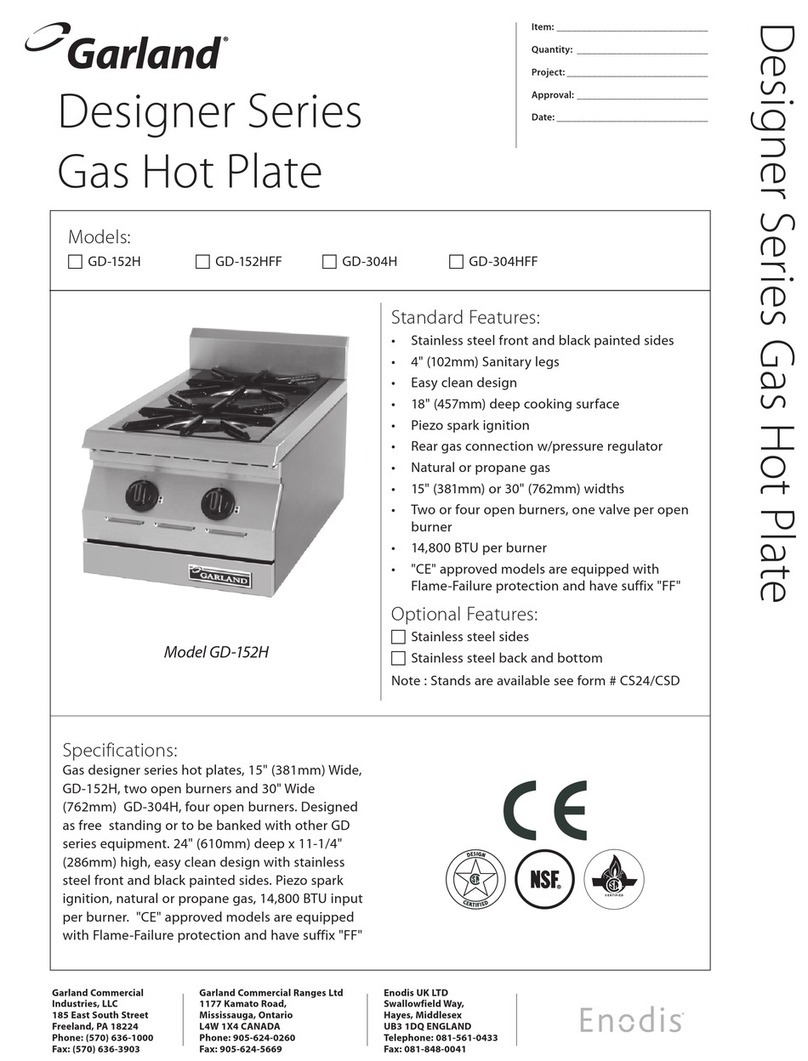

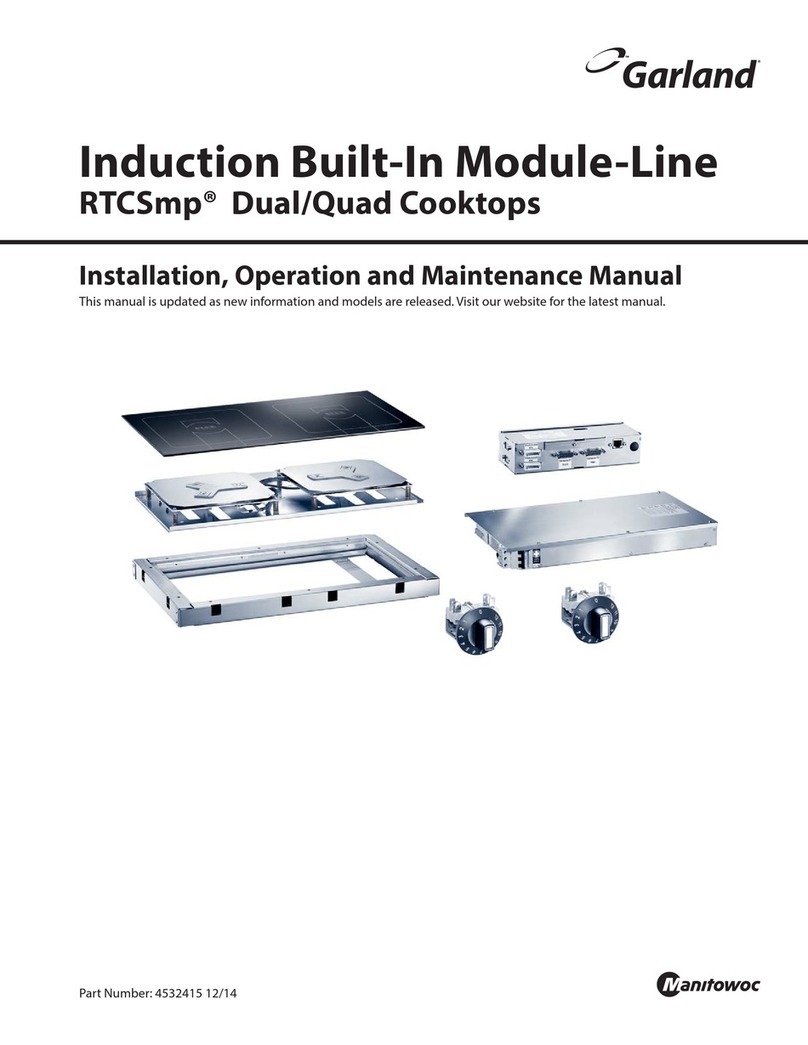

Constructions

The cookers are made of stainless steel (CNS 1.4301). The case is sealed. The mounting

of the vitrocerame as well as of the ceramic bowl is done with screws.

3Functioning

3.1 Adjusting the performance rate

The performance rate is adjusted by the potentiometer (control knob). The inductive

performance is depending on the position of the potentiometer: Position 1 = minimum

power, Position 10 = maximum power.

3.2 Checking the temperature

Induction coil

The temperature of the induction coil is checked by a temperature sensor. If the coil is

heated over the maximum power, the heating process is stopped. As soon as the coil has

cooled down, the Induction unit may be re-started. Turn the position of the kontrol knob on

„0“ and then on the desired power.

Power board

The temperature of the power board is checked by a temperature sensor. As soon as the

heat sink is heated over 55ºC/130ºF, a cooling fan is started. Temperatures of the heat

sinks of more than 70ºC/ 160ºF will reduce automatically the checking of the power in order

to keep the induction cooker working under normal conditions.

Print

The temperature of the print is checking the ambient temperature of the appliance. As soon

as the temperature is higher than the programmed value the heating process is stopped. It

can be re-started as soon as normal conditions are reached.

3.3 Protection overload current

Detecting inapproriate pan material or magnetic objects on the heating area, the current in

the induction coil may be essentially raised. In order to protect the power board,

the current in the coil is checked. As soon as the current in the coil exceeds the tolerance,

the generator is blocked and there is no further aktive exchange of energy. He will be re-

started as soon as normal working conditions are reached.