Garmat 99270 Instruction manual

FOR YOUR SAFETY

If You Smell Gas:

1. Open Window

2. Don't Touch Electrical Switches

3. Extinguish Any open Flame.

4. Immediatly Call Your Gas

Supplier

The use ans storage of gasoline or

other flammable vapors and liquids

in open containers in the vicinity of

this appliance is hazzardous.

WARNING: Improper installation,

adjustment. alteration, service or

maintenance can cause property

damage, injury or death. Read the

installation, operating and

maintenance instructions throughly

before installing or servicing this

equipment.

NOT FOR RESIDENTIAL USE.

FOR YOUR SAFETY

1

Garmat®USA, Models 99270, 99273,

& 99275 Direct Gas-Fired Industrial

Heater

HEATER DESCRIPTION

The Garmat®USA, Inc. heater is a

direct gas-fired fresh-air appliance. It is

designed for indoor installation, outdoor

installation with the proper sheltering

from weather, with fresh outdoor air

delivered to the combustion zone. The

heater is designed for use with natural

gas or LPG ( check the heaters' rating

plate). The direct gas-fired burner will

modulate to maintain the selected air

discharge temperature. This appliance is

most suited for use with spray paint

booths and associated equipment. It

does, however, fill the need for non-

recirculating building air make up.

INSTALLATION CODES

This equipment is designed and

manufactured to provide years of safe

and efficient operation. In order to retain

these features, The installer (s) need to

achieve certain installation and operation

requirements. These requirements will

be defined throughout this manual and

should be specifically noted.

The type of fuel used with this

equipment and it’s proper firing rate are

shown on the appliance rating plate.

Electrical characteristics are shown on

the rating plate as well. If the need for a

change in fuel type occurs, the

manufacturer must be consulted.

WARNING: THIS UNIT IS NOT

FOR INSTALLATION ON

COMBUSTIBLE MATERIALS.

THIS UNIT IS TO BE INSTALLED

ON CONCRETE OR OTHER NON

COMBUSTABLE SURFACES.

WARNING: CLEARANCE

AROUND THE UNIT TO

COMBUSTIBLES SHOULD BE NO

LESS THAN 4” (FOUR INCHES).

This equipment shall be installed in

accordance with the standards of the

National Fire Protection Association and

the National Fuel Gas Code ( NFPA 54

).

Local authorities having jurisdiction

must be consulted first to verify local

codes and installation procedures. In the

absences of such codes and installation

procedures, the unit shall be installed in

accordance with the National Fuel Gas

Code ANSI Z223.1 - Latest addition.

HEATER INSTALLATION:

CONFIGURATION AIR BOX

INSTALLATION

The Garmat®USA air make up units are

equipped with a configuration air box

(“C” box). This “C” box needs to be

attached to the top of the make up unit

utilizing 3/4” number 8 self drilling

screws. The screws should be sent

through the framing of both the unit and

the “C” box to ensure it’s security.

2

ROOF TOP INSTALLATION

The Garmat®USA air make up units are

not designed as exterior structures.

NOTE: GARMAT® USA INC, DOES

NOT RECOMMEND

INSTALLATION OF THE

HEATING UNIT OUTDOORS.

INDOOR SUSPENSION

MOUNTING

A support system must be made by

installers to support the entire air make

up unit. It is recommended that this

support system be suspended by 1/2” -

13 threaded rod (or greater).

WARNING: IF SERVICE

PLATFORM IS REQUIRED,IT IS

THE INSTALLERS

RESPONSIBILITY. IF PLATFORM

IS ADDED, ADDITIONAL WEIGHT

MUST BE ADDED TO TENSILE

STRENGTH. REQUIREMENTS

FOR BUILDING STRUCTURE.

CAUTION: DURING

INSTALLATION, VIBRATION

ISOLATION SHOULD BE

INSTALLED TO PREVENT

TRANMISSION TO THE

BUILDING STRUCTURE.

BELTS & DRIVES

After unit is connected to utilities and is

ready for start up, install fan belts and

sheaves. Adjust for proper belt tension.

Proper tension is achieved when the belt

can be depressed 1/2” with moderate

pressure at mid point between the motor

and the fan sheves.

The Garmat®USA, Inc. air make up

unit comes with solid bushing mounted,

and variable sheaves. If adjustment to

air through-put is needed, the vairable

sheaves can be adjusted. Always check

motor amperages to ensure that loads

stay within the motors’ electrical plate

ratings. Failure to do so will void motor

warranty. After adjustments are made,

the variable sheaves must be secured

with thread lock.

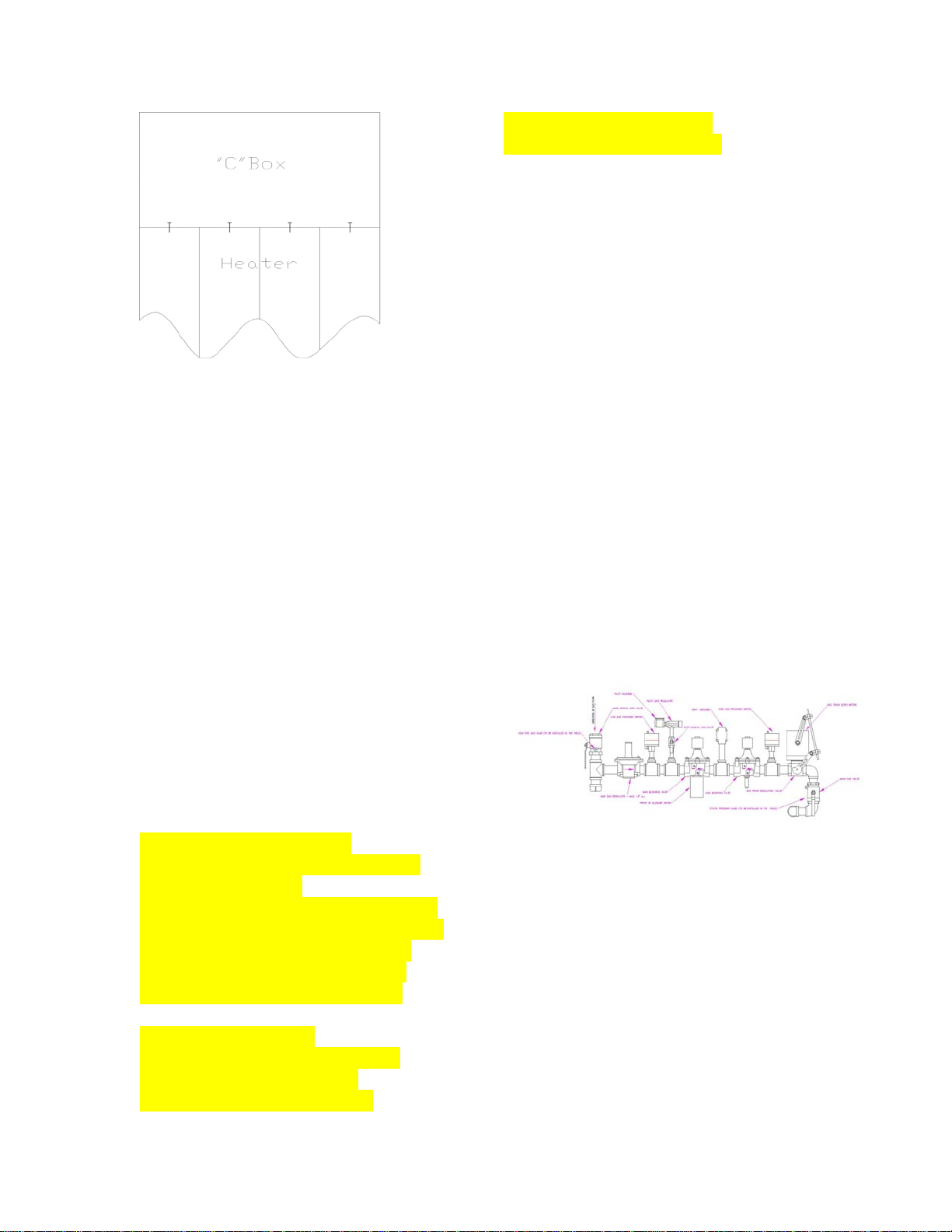

GAS MANIFOLD

The Garmat®USA, Inc. air make up

units are equipped with one manifold

designed to meet IRI requirements.

The gas train of the air make up unit is

suitable for connection to supply

pressures from 21” WC maximum to 7”

WC minimum for natural gas and 5”

WC maximum to 3” WC minimum for

propane (LPG). Capacity for both types

of fuel are to provide input to specified

3

burner size. Model 99270 have 0.84

MBTU burner. Model 99273

has a 1.0 MBTU burner and model

99275 has a 1.5 MBTU burner.

The gas pipe connection size for the

model 99270 will be 1” and for the

models 99273 and 99275 will be 1 1/4”.

A drip leg or trap at the inlet of the gas

manifold is provided.

WARNING: PIPING MUST BE

ADDED IN ORDER TO INSURE

GAS TRAIN VENT IS PIPED TO

THE OUTSIDE OF BUILDING.

FAILURE TO DO SO WILL CAUSE

GAS TO VENT INTO THE

BUILDING AROUND THE

MANIFOLD.

WARNING: ALL COMPONENTS

OF THE GAS SUPPLY SYSTEM

MUST BE LEAK TESTED PRIOR

TO PLACING EQUIPMENT INTO

OPERATION.

ELECTRICAL:

WARNING: SPARK TESTING OR

SHORTING OF THE CONTROL

WIRES BY ANY MEANS WILL

DAMAGE THE CONTROL PANEL

AND VOID THE WARRANTY.

All electrical wiring and connections,

including electrical grounding, should be

made in accordance with the National

Electric Code ANSI/NFPA 70 current

addition.

Although the Garmat®USA, Inc. air

make up units are for use in most

commercial heating applications, the

main application of the unit is for use

with a paint spray booth. The use of two

120 volt 20 ampere circuits for lighting

will need to be supplied to the unit when

used in conjunction with a paint spray

booth.

The motor requirements are as follows:

for 3 PH, 10 HP units, 208 volt AC

requires 30.8 Full Load Amperage

“FLA”, 230 volt AC requires 28 FLA

and 460 volt requires 14 FLA. For

single phase, 10 HP motors 230 volt AC

requires 50 FLA. The single phase

motors are not available and a roto-phase

inverter or buck booster is required and

not provided by Garmat USA®.

For Three Phase 15 HP units, 208 volt

AC requires 46.2 FLA., 230 volt AC

requires 42 FLA., 460 volt AC requires

21 FLA. The single phase motors are not

available.

For control voltage a transformer is

provided to convert the motor voltage to

the proper control voltage/s.

NOTE: ALL MOTOR AMPERAGE

FIGURES ARE BASED ON NEC.

LOCAL REQUIREMENTS MAY

VARY.

WARNING: ELECTRICAL AND

IGNITION SYSTEMS MUST BE

PROTECTED FROM DRIPPING

WATER. IMPROPER

INSTALLATION, ADJUSTMENT,

ALTERATION, SETRVICE, OR

MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR

DEATH. READ THE

INSTALLATION, OPERATING

AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

SAFETY SYSTEM

4

Manual High Limit ( All models )

If any situation occurs creating a

temperature reaching 200° F at the air

discharge, power to the gas train

circuitry will be terminated. At this point

none of the operating components of the

gas train will function. To reactivate the

gas train the reset button on the limit

switch must be depressed. The main

application of this heater is for use with

a paint spray booth and a additional high

limit thermostat is provided for use in

the spray mode to shut down the gas

train if the discharge air temperature

reaches 165 deg. F. This high limit is

automatically resetting.

Air Flow Sensor ( All models )

Air flow sensors are connected directly

to the flame guard device.When a loss or

lack of air flow, or to much air flow

across the burner is sensed, the flame

guard device will terminate power to the

pilot solenoid and the connection of the

temperature controller to the gas train

modulator. The through-put air around

the burner will need to be reestablished,

or reduced for the burner to fire.

Flame Guard Device ( All models )

The flame guard is a device that will

check the burner for pilot during

initiation and for pilot and main flame

during full operation. The flame guard

device uses a flame rod installed in the

burner which will thermally induce a 15

- 18 volt DC signal in the flame guard

device. During initiation there is a 10

second trial period. At the end of this

time if there is no flame in the pilot area,

the flame guard will lock out the burner

system. The flame guard will need to be

manually reset to start initiation. It does

not re-attempt initiation automatically.

The flame guard is a “one try” system

that will require manual reset each time

the device locks out. When a flame

depletes or disappears in the burner

during full operation, the flame guard

will have a 10 second delay and will

lock out the burner system. The flame

guard will need to be manually reset at

this point.

Temperature Control System

( Models 99270 )

The system uses an analog temperature

controller with analog input and a 100%

symmetrically modulating gas valve.

The thermister connected to the

temperature control will be placed in the

air output of the make up air unit. The

temperature controller internally limits

the discharge temperature to 170° F

when shipped. The manual high limit

will act as a back up to this.

Temperature Control System

( Models 99273 and 99275 )

This system uses a digital temperature

controller, a 100% modulator and a

symmetrically modulating gas valve.

The thermocouple connected to the

temperature control will be placed in the

air output of the make up air unit. The

temperature controller internally limits

the discharge temperature to 190° F

when shipped. The manual high limit

will act as a back up to this.

FREEZE THERMOSTAT

( All Models )

5

In areas where the ambient temperature

can fall below –20 deg. F, it is

recommended that a low temperature

limit control (freeze thermostat ) be

installed (not provided by Garmat

USA®. The low temperature control

shall be installed in series with the high

limit switch in the gas train safety

circuit.

High Gas Pressure Switch

( Models 99273 and 99275 )

This component is on the gas manifold

and will disconnect electrical power to

the gas train circuit before reaching the

flame guard device. In the event that

more than 21” WC of gas pressure enters

the gas manifold at this point, the switch

will disconnect the power and will need

to be manually reset.

Low Gas Pressure Switch

( Models 99273 and 99275 )

This component is on the gas manifold

and will disconnect electrical power to

the gas train circuit before reaching the

flame guard device. In the event that less

than 3” WC of gas pressure enters the

gas manifold or pressure drops below

this point, the switch will disconnect the

power and will automatically reset when

pressure is restored.`

Proof Of Closure Switch

( Models 99273 and 99275 )

This switch is mounted directly under

one of the blocking valves on the gas

train and is linked to the valve actuator

and proves that the valve is closed

before allowing electrical power to

continue through the gas train circuit.

Cabin Pressure Control System

( Model 99270 )

A manual ¼ adjust lever is provided at

the exhaust pressure damper. A slack

tube manometer is provided for

montering the cabin pressure.

( Models 99273 and 99275 )

The remote control panel contains a

photohelic gauge. This gauge is

displayed on the face of the remote panel

and controls the air pressure within the

cabin. This gauge is adjustable using the

two orange needles visible on the face of

the gauge. The gauge operates a

modulating motor attached to exhaust

pressure damper. Opening the cabin will

cause loss of cabin air pressure.

PROGRAMMABLE LOGIC

CONTROLLER ( PLC )

( All Models)

The electrical panel contains a

programmable logic controller ( PLC ).

The PLC controls all of the automatic

functions of the control sequence

including flash-off time duration, bake

time duration and cool down time

duration. Bake time duration is set at the

remote panel on the 99270 deluxe,

99273, 99275 models. On the model

99270 the bake timer is internal in the

PLC. Flash-off time duration and cool

down time duration are internal

functions of the PLC and are set at the

factory. The factory setting of the flash-

off time duration is three minutes and for

the cool down time duration is ten

minutes. These time durations can be

reset by your authorized local authorized

distributor.

6

OUTDOOR VENTILATION AIR

( All Models )

Outdoor air must be ducted to the air

make up unit inlet when unit is installed

inside of a building. This ducting shall

be no smaller than 30” square or the

equivalent in crossectional surface area

in diameter of round ducting. Bends or

transitions are not recommended and

length should be kept to less than 5

meters or 16.5 feet. If bends or

transitions are required, turning vanes

are recommended.

LINE PRESSURE TEST

( All Models )

The make up unit and its inlet manual

gas valve must be disconnected from gas

supply piping during any pressure

testing above 21” WC. The air make up

unit must be isolated from the gas supply

system by closing the manual gas valve

up stream of the regulator on the inlet of

the gas manifold.

PROPER SEQUENCE OF

OPERATION

The Garmat®USA Inc. air make up unit

can be ordered with several different

usage options. To simplify the sequence

of operations, all four available options

will be covered.

There are four modes of operation:

Power On, Run or Spray, Recycle or

Bake and Shut Down.

Power On

( Models 99273 & 99275 )

The three phase voltage supplies power

to the control transformer. The 120, and

24 volt is connected through the control

transformer. When the power switch and

spray switch are actuated, power is given

to the motors. If either exhaust fan motor

starter or the supply motor starter trips

out on overload the respective motor and

make up unit operations will cease until

respective motor starter is reset. Both

control voltages are protected with

breakers in the main electrical panel.

A 120 volt jumper is provided in the

main control panel which can be

connected through a NC contact on a

micro switch used for a fire suppression

system.

When The NC contact is opened, the 120

volt control supply is removed from the

circuit and the entire unit shuts down.

The EM (Emergency stop) switch on the

remote control panel does the same.

Rotating the EM switch reconnects the

120 volt supply, unless the fire system

has not been reset.

The green light will illuminate when the

EM switch is rotated clockwise. The 120

volt control power is connected through

the EM switch in the remote control

panel. If either motor starter trips out on

overload, a red light will illuminate for

the respective motor and make up unit

operations will cease until respective

motor starter is reset. Both control

voltages are protected with breakers in

the main control panel.

Run or Spray

( Models 99270 and 99270-E )

With the OFF switch on the spray cycle

can be started by pushing the SPRAY

switch. The air make up will run in the

7

spray mode until it is switched to either

the OFF switch or the BAKE switch is

pushed. The SPRAY mode provides 120

volt to the PLC, which in turn supplies

120 volt to starter SM2 and the

temperature controller in the remote

control panel. SM2 is present for

controlling an exhaust motor. As soon as

SM2 is energized, 120 v power is

supplied to SM1 through the PLC after a

timed delay. SM1 is provided for

controlling the motor contained within

the air make up unit and a timed delay

will still be present to delay start up.

SM1 allows 120 volt power to be

supplied to the green light for the supply

motor and the burner thru the PLC. Both

are located on the remote control panel.

When the burner switch is set to the

winter position, 120 volt power is

provided to the PLC, which supplies 120

volt power to the gas train power circuit.

When the burner switch is in the summer

position the gas train power circuit will

not be energized in the SPRAY mode.

Bake

( Models 99270 )

With the OFF switch on and the SPRAY

switch on Placing the BAKE switch in

BAKE provides 120 volt power through

the PLC internal bake timer. For the

99270 deluxe model the bake timer is

located on the face of the remote panel.

The BAKE switch supplies 120 volt

power to the PLC in the main control

panel, which begins the delay cycle. The

purge timer should be set for a minimum

of 3 minutes. At the completion of the

delay cycle, 120 volt power is supplied

to the change over damper solenoid. In

turn, the change over damper is opened

pneumatically releasing the damper air

valve. When the damper valve is

released, the change over damper

solenoid is energized, the compressed air

solenoid is de-energized. The lighting

circuit is also removed from 120 volt

supply. This drops out the lighting and

compressed air source for spray. The

PLC supplies 120 volt power to the gas

train power circuit.

In bake the PLC places the temperature

controller in the second set point or 2SP.

This is the bake mode setting.

At the end of the programmed bake time,

whether 1 or 999 minutes, the PLC

initiates the shut down mode.

Shut Down

The bake timer initiates the timed shut

down mode. The supply to the change

over solenoid is also restablished. The

change over damper closes. The lights

come back on and the temperature

controller returns to the first set position,

SP. If burner switch is in the summer

position, the PLC will shut off the gas

train circuit.

At the end of the timed cool down cycle

(1 to 10 minutes), all functions of the

unit will shut down completely, with the

exception of the lights. The PLC

interrupts the 120 volt power to the

exhaust fan, the intake fan and the

burner circuit. The lights in the booth

will remain “on” until switched off. The

PLC will hold the unit in the “off” status

until the power is interrupted to the

system by pushing the OFF switch to

“off” and back “on”.

Bake

( Models 99273 and 99275 )

8

Placing the OFF-SPRAY-BAKE switch

in BAKE provides 120 volt power

through the PLC to the bake timer

located on the remote control panel and

power to the change over damper

solenoid. The timer will begin the timing

sequence. The bake timer should be set

in the “C” mode on the left of the timer

face and the “M” mode on the right. “M”

is for minutes.

The bake delay timer supplies 120 volt

power to the PLC in the main control

panel, which begins the delay cycle. The

bake delay timer should be set for a

minimum of 5 minutes. At the

completion of the delay cycle, 120 volt

power is supplied to the change over

damper solenoid. In turn, the change

over damper is opened pneumatically

releasing the damper air valve. When the

damper valve is released, the

compressed air solenoid is de-energized

and the lighting circuit is removed from

120 v supply. This drops out the lighting

and compressed air source. The PLC

supplies 120 volt power to the gas train

power circuit.

The PLC places the temperature

controller in the second set point or 2SP.

This is the bake mode setting.

At the end of the programmed bake time,

whether 1 or 999 minutes, the PLC

initiates the shut down mode.

Shut Down

The bake timer initiates the timed shut

down mode. The supply to the change

over solenoid is also interrupted. The

change over damper closes. The lights

come back on and the temperature

controller returns to the first set position,

SP. When the burner switch is in the

summer position, the PLC shuts off the

gas train circuit.

At the end of the timed cool down cycle

(1 to 10 minutes), all functions of the

unit will shut down completely. The

PLC interrupts the 120 volt for all

components, including the exhaust fan,

intake fan, and burner circuit and holds

the unit in an “off” status until the

OFF/SPRAY/BAKE switch is set to the

OFF position. The shut down mode can

be interrupted at any time by switching

the unit to Spray.

GAS TRAIN POWER CIRCUIT

( Models 99270 )

With the OFF switch on and the SPRAY

switch in the SPRAY position and the

burner is in the WINTER position, or if

the BAKE switch is in the BAKE

position the PLC provides 120 volt

power through the Manual High Limit.

This allows 120 volt power to be

provided to the Flame Guard Device.

The Flame Guard Device starts a 7

second delay before ignition. When this

time delay is finished, both the ignition

transformer and the pilot solenoid are

energized. If the flame rod in the burner

provides proof of flame to the Flame

Guard Device, the ignition transformer is

shut down and the normally open vent

valve is closed and the main gas valves

open. After the main gas valves have

opened, the PLC closes the circuit

between the temperature control and the

gas manifold modulating valve.

If the Flame Guard Device does not

receive proof of flame in the burner

within 10 seconds, the pilot solenoid and

the ignition transformer will be de-

energized. The Flame Guard Device will

shut down the gas train.

9

The burner green light is denergized on

the remote control panel. The Flame

Guard Device will need to be manually

reset to start the process over.

GAS TRAIN POWER CIRCUIT

( Models 99273 and 99275 )

When the OFF-SPRAY-BAKE switch is

in the SPRAY position and the burner is

in the WINTER position, or if the OFF-

SPRAY –BAKE switch is in the BAKE

position the PLC provides 120 volt

power to the Low Gas Pressure Switch.

The 120 volt power continues to the

High Gas Pressure Switch and proceeds

to the Proof of Closure Switch,

continuing to the Manual High Limit.

All of these components must allow the

120 volt power to be provided to the

Flame Guard Device. When the 120 volt

power reaches the Flame Guard Device

it passes through directly to the High Air

flow Sensor and the Low Air Flow

Sensor. The Air Flow Sensors prove air

flow and the Flame Guard Device starts

a 7 second delay before ignition. When

this time delay is finished, both the

ignition transformer and the pilot

solenoid are energized. If the flame rod

in the burner provides proof of flame to

the Flame Guard Device, the ignition

transformer is shut down and the

normally open vent valve is closed and

the main gas valves are opened. After

the valves are open, the PLC closes the

circuit between the temperature control

and the gas manifold modulating valve.

If the Flame Guard Device does not

receive proof of flame in the burner

within 10 seconds, the pilot solenoid and

the ignition transformer will be de-

energized. The Flame Guard Device will

send a signal to the PLC. The PLC

switches the 120 volt power from the

burner green light to the burner red light

on the remote control panel. This also

de-energizes the gas train power circuit.

The Flame Guard Device will need to be

manually reset to start the process over.

COMPRESSED AIR FOR SPRAY

APPLICATION WITHIN BOOTH

( All Models )

A solenoid is provided to control the

compressed air source in a paint spray

booth. It is located in the main control

panel. 120 v power is provided to the

solenoid through the PLC to the exhaust

pressure switch, door air switch and

return air switch. The make up unit must

be in the Spray mode for compressed air

to be provided to the spray booth.

CHECK, TEST, START UP

PROCEDURES

( All Models )

CAUTION: HIGH VOLTAGE

PRESENT IN PANEL

Before Start Up

1. Inspect roof caps, inlet, and outlet of

the air make up unit for any debris that

can block airflow.

2. With multimeter, test motor voltages

to assure that they agree with the tag on

the unit. In addition, test the lighting

voltage. Make sure that the breakers at

the building panel and/or the fuse in the

disconnect match the amperage ratings

on the makeup units’ information tag.

3. Inspect the burner to assure that the

assembly is tight and in the proper place.

Inspect the flame rod, ignitor and pilot

10

gas tube for tightness and good

connection. Make sure that the air flow

sensor tube is tight and well connected.

4. Perform gas pressure test at test port

on inlet manual gas valve and assure that

the maximum pressure listed on the unit

information tag is not exceeded. In

addition, check that there is enough gas

pressure and capacity for burner size.

5. Check all gas lines and gas manifold

for leaks.

6. Double check all electrical

connections to the unit.

Start Up

1. Bump start the motors and check for

proper rotation. Correct rotation if

necessary.

2. Connect amp probe to motor circuits

and turn unit on. Document amperages

for each power leg and date. Assure that

motors are within their motor plate

amperage ratings. Leave documentation

in the control panel and send copy with

warranty information to manufacturer.

3. Install gas pressure gauges on the on

manual gas valves of the gas train. After

unit is up and running, turn burner on.

While waiting for gas train safety to

complete it’s cycle, turn burner manifold

manual gas valve off. When ignition

sequence has completed and pilot flame

is present, use the pilot orifice on the gas

manifold to adjust the pilot flame to

approximately four (4) inches in height,

or the size of a fist. If a freeze thermostat

is install for extremely cold climates,

( below -20 deg. F. ) the burner will not

start if the temperature across the burner

is below –20 deg. F.

4. Adjust high fire setting by viewing

gas meter at the test port on the burner

manifold manual gas valve.

Set the temperature controller on the

remote control panel to the manual

setting and set output to 100 %. Open

the burner manifold manual gas valve

long enough to acquire reading and close

the valve. The pressure should be 4.2”

WC minimum and should not exceed

5.2” WC maximum. Adjust regulator if

necessary and test again. Set temperature

controller back to 0.0 % output and open

output manual gas valve.

5. Adjust the burner ribbon with the

temperature control in the manual setting

and set to 0.0 % output. Viewing the

burner, adjust the zero increase

potentiometer in the top of the gas

manifold modulating motor. Adjust the

zero increase until a small flame is

ribboning across the bottom of the

burner trough. When adjustment is

correct, set temperature control back to

the auto setting. Increase and decrease

the temperature setting on the

temperature control to check for proper

operation.

6. Set the bake timer to 5 minutes. On

99270 model push the SPRAY and the

BAKE switches. On the 99273 and

99275 units set the OFF/SPRAY/BAKE

switch to the BAKE position. Wait for

change over to occur. After 3 minutes

the dampers should change over to

recycle. When the bake timer times out,

the cool down cycle will begin. The

entire unit should shut down after the

cool down cycle is complete.

7. Test air through- put and change

sheaves if necessary.

11

MAINTENANCE INSTRUCTIONS

( All Units )

1. Motor bearings should be lubricated at

4 month intervals.

2. Drive belts should be adjusted at least

two times during the first two hours of

operation. Adjust for 1/2 inch deflection

with medium pressure at middle of belt

span. Belts should be replaced annually.

3. Blower wheel should be periodically

inspected for build up of dust or dirt and

cleaned if necessary.

4. Annually check the burner and

components. The flame rod should be

changed annually.

5. The air flow sensing switch and

tubing should be checked periodically

for obstructions or debris.

6. The metallic inlet air filters should be

cleaned in 4 month intervals. Observe

the air flow direction indication on the

filter frame when reinstalling.

12

TROUBLE SHOOTING CHART

SYMPTOM POSSIBLE CAUSE ACTION RECOMMENDED

NOTHING WORKS EM switch is off. Incoming 1 PH Turn EM switch on. Check

(GREEN POWER LIGHT voltage is off. The 120 volt for incoming 3 phase voltage.

IS NOT ON) control breaker in main panel Reset breaker in main

is tripped. control panel.

NOTHING WORKS Overload relay is tripped. loss Reset overload relay. Check

(RED POWER LIGHT of phase. Low 3 phase voltage. for 3PH. Measure 3PH

IS NOT ON) voltage.

EVERYTHING WORKS Lighting breaker(s) tripped. Reset lighting breaker(s).

EXCEPT BOOTH LIGHTS Change over damper stuck Check change over damper.

open Control air is off. Ensure control air is set at

40-60 PSI.

TEMPERATURE DOES NOT Outside air temperature is Increase set point on

RISE (BURNER GREEN greater than set point. Temperature control. Reset

LIGHT IS ON) High limit is tripped. Low gas high limit. Check low and

Pressure. High gas pressure. High gas switches. Check

Proof of closure switch is open. Proof of Closure switch. If

problem persists call an

authorized Garmat® service

technician.

TEMPERATURE DOES NOT Pilot has failed during ignition Push red reset button on

RISE ( BURNER RED LIGHT cycle. Pilot manual gas valve red box marked Fireye.

IS ON. Turned off. Turn manual pilot valve on.

If lockout continues , call

Garmat® authorized service

Technician.

TEMPERATURE TOO HIGH Controller set in second set point. Check temperature

DURING SPRAY MODE. Outside temperature above 70 º controller display. Set burner

Fahrenheit. Switch to summer setting.

13

This manual suits for next models

2

Table of contents

Other Garmat Service Equipment manuals

Popular Service Equipment manuals by other brands

Magneti Marelli

Magneti Marelli ATF EXTRA PRO user manual

Hyundai

Hyundai Midtronics GRX-5100 instruction manual

Tronair

Tronair 01-1229-0011 Operation & service manual

ULTIMATE SPEED

ULTIMATE SPEED HG02236 Assembly and Safety Advice

CEMB

CEMB DWA1000CWAS manual

Invacare

Invacare TDX SP Assembly, installation and operating instructions