Garmat Frontier Manual

Operations & Maintenance Manual

Frontier Spray Booth

1401 W. Stanford, Englewood, Colorado 80110

Phone: (800) 442-7628 Fax: 303-781-2683

www.garmat.com

BUILT IN THE

USAJune 22, 2004

OPERATIONS AND MAINTENANCE INSTRUCTIONS

OPERATIONS INSTRUCTIONS…………………………………………. Page 3

MAINTENANCE INSTRUCTIONS………………………………………. Page 7

MAINTENANCE SCHEDULE.………………………………………….. Page 9

TROUBLESHOOTING…………………………………………………….. Page 11

OPERATION SEQUENCE………………………………………………… Page 11

FILTER CHANGE RECORD……………………………………………… Page 17

WARNING LABLES……………………………………………………… Page 18

3

OPERATIONS INSTRUCTIONS ENCLOSED

PAINT BOOTH

Garmat® Booth/Oven

WARNING: FAILURE TO HEED

WARNINGS INCLUDED IN THIS MANUAL

COULD RESULT IN PROPERTY DAMAGE,

PERSONAL INJURY, AND/OR DEATH.

The Garmat® Frontier Paint Booth is designed and

manufactured in the United States. The Garmat®

Frontier Paint Booth provides the optimal

environment for the application of fine automotive

finishes. Through continuous product design and

improvement, Garmat® is committed to providing

you and your customer with the finest automotive

finish possible. Thorough study of this manual will

not only aid you in your pursuit of a fine finish, it

will assist you in making your pursuit safer and

easier.

SUGGESTIONS FOR SAFETY

Before using this unit be sure to read all of the

operation instructions and these safety suggestions

carefully. Afterward, place them in the main control

panel of the booth for future reference. Take special

care to follow the warnings indicated on the unit, as

well as the operating instructions.

PREPARATION OF THE CAR

One of the key elements of a fine finish is a dust free

environment. The design of a Garmat Frontier Paint

Booth is centered on providing a relatively dust free

environment. Your preparation of the car before it

enters the booth is very important to maintain a dust

free environment.

Before moving the car into the spray booth, after the

body of the car is properly prepared to accept the

finish, wash the entire vehicle. Attention during the

wash procedure should be directed to the underside

of the vehicle as well. When the vehicle is

completely dry and ready for refinishing, the entire

vehicle should be blown off with compressed air.

Again, attention must be paid to crevices around

the hood, trunk lid, doors, air vents, etc.

Masking of the vehicle should be performed

outside of the booth. Remember, your efforts to

introduce a clean vehicle into a relatively dust-free

environment provided by the Garmat Frontier

Paint Booth will assist you in your pursuit of the

finest finish with a minimum of work.

PREPARATION OF THE PAINTER

Proper protective clothing and gear is essential for

the safety of the painter and production of a quality

paint job. Paint suits are readily available in a

variety of styles. Garmat recommends a close

weave nylon type that breathes and has a hood.

The suits should be cleaned regularly and should

be worn only when the painter is actually engaged

in painting. The painter should remove all dust

from his clothes before putting the paint suit on.

Whenever entering the Paint Booth, all dust should

be removed from the paint suit, and any

equipment. Anything that the painter brings into

the booth is a potential cause of dust.

WARNING: APPROVED RESPIRATORS

MUST BE WORN WHENEVER FINISHES

ARE APPLIED.

NOTE: THE BOOTH MUST BE

OPERATING WHENEVER ENTERING

THE BOOTH

The Painter should try to stay in the booth as much

as possible and limit going in and out between

paint coats. He should have enough paint in the

booth to complete that portion of the job.

PAINT BOOTH ENTRY

The Garmat® Frontier Paint Booth can be installed

in a variety of configurations. Your Paint Booth as

installed will include some of the following

features:

4

FRONT ENTRY

DRIVE-THROUGH

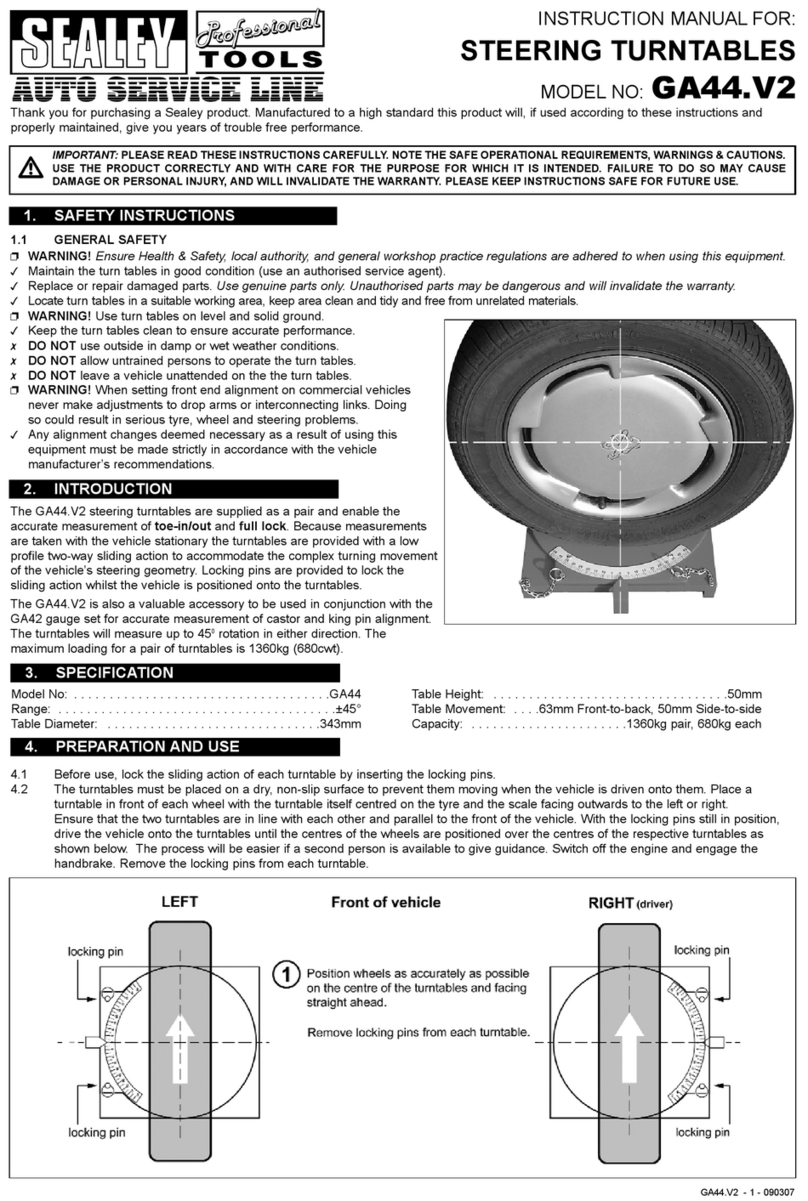

Always center vehicle side-to-side, and front to back

on pit or floor.

NOTE: THE BOOTH FANS MUST BE

RUNNING WHENEVER A CAR IS MOVED

IN OR OUT. THIS WILL REDUCE THE

POSSIBILITY OF CONTAMINATION

FROM THE SHOP

FRONT ENTRY AND DRIVE THROUGH:

Before moving a vehicle into the booth, assure that

the vehicle and/or any attachments, i.e. mirrors,

antennas, etc. will fit through the door you intend to

use. All recommended preparation procedures

outlined above must be completed. The booth must

be operating. Vehicles should be driven slowly and

carefully. Rapid acceleration or hard braking should

be avoided at all times.

SUGGESTIONS FOR SAFETY

Before using this unit be sure to read all of the

operating instructions and these safety suggestions

carefully. Afterward, place them in the main

electrical control panel for future reference. Take

special care to follow the warnings indicated on the

unit itself as well as the operating instructions.

WARNING: IF YOU SMELL GAS:

1. OPEN WINDOWS.

2. DO NOT OPERATE ELECTRICAL

SWITCHES.

3. EXTINGUISH ANY OPEN FLAME.

4. IMMEDIATELY CALL YOUR GAS

SUPPLIER.

WARNING: DO NOT USE OR STORE

GASOLINE, PAINT, OR OTHER

FLAMMABLE MATERIALS NEAR THE

INTAKE AIR HEATER APPLIANCE (BOOTH

MECHANICALS).

WARNING: WHEN VEHICLES ARE

EQUIPPED WITH PROPANE (LPG) FUEL,

THE FUEL TANK MUST BE LESS THAN

HALF FULL BEFORE MOVING THE

VEHICLE INTO THE BOOTH. THE

PROPANE (LPG) TANK MUST HAVE

ROOM FOR EXPANSION WITHIN THE

TANK DURING BAKE CYCLE.

WARNING: DO NOT ENTER THE BOOTH

DURING THE BAKE CYCLE.

WARNING: APPROVED RESPIRATORS

MUST BE WORN WHENEVER FINISHES

ARE BEING APPLIED.

The booth fans must be running whenever a car is

moved into or out of the booth. The booth must be

running whenever personnel are entering the

booth.

Consult with your paint jobber or manufacturer

concerning recommended refinishing

temperatures, recommended bake temperatures

and times.

WARNING: DO NOT EXPOSE THIS

EQUIPMENT TO EXCESSIVE MOISTURE

OR RAIN. DO NOT PRESSURE WASH OR

HOSE WASH THE INTERIOR,

EXTERIOR OF THE CABIN OR ITS’

RELATED EQUIPMENT. THIS WILL

VOID THE CABIN WARRANTY.

Review the recommended maintenance procedures

and insure that the prescribed schedule is followed.

Disconnect all electrical supply and lock-off

whenever covers on the mechanicals are removed

for maintenance procedures.

Do not over-tighten the fan belts. Proper tension is

when there is ½” deflection at a mid point between

the pulleys with moderate pressure on the belt. Belt

5

tension testers are available from drive belt suppliers.

Drive belts should be adjusted after the first 40 hours

of use and every three months after that.

In addition to adjustments explained in the

maintenance instructions, you may attempt repairs

your self. However, if you are not sure how to repair

the unit, be sure to request service from a qualified

technician or your local distributor.

THE CONTROLS

Identification of components. The control

components are located on the face of the Remote

Control Panel. There are three available options for

control of the booth.

44006(X) STANDARD FRONTIER:

1. SPRAY SWITCH, is a black push button

switch that will start the intake and exhaust

fans when pushed.

2. OFF SWITCH, is a black push button

switch that will turn off the intake and

exhaust fans when pushed.

3. LIGHT SWITCH, is a toggle switch that

turn the lighting on and off.

4. INCREASE/DECREASE PRESSURE

SWITCHES, are black push buttons that

open and close the pressure damper.

46008(X) DELUXE FRONTIER:

1. EMERGENCY (EM) STOP SWITCH is red

in color.

2. LIGHTS ON/OFF SWITCH

3. OFF/SPRAY/BAKE SWITCH OR

OFF/SPRAY SWITCH

4. BURNER SUMMER/WINTER SWITCH

5. POWER PILOT LIGHT (GREEN) indicates

booth is ready for or already in operation when lit.

6. THE INTAKE PILOT LIGHT (RED), THE

EXHAUST PILOT (RED) OR THE BURNER

PILOT (RED), when lit indicates a problem exists

with the Intake Motor, the Exhaust Motor, or the

burner safeguard system.

7. HOURMETER records hours of operation in

the spray mode. The hour meter is used to

schedule filter replacement.

8. BAKE TIMER is energized only during the

bake mode. This timer features a bar (top portion

of unit), which initializes at 100% at the right and

decreases to 0 at the end of the timed period. The

mode indication (lower left corner of the timer)

should be set at C. The bake time is set via

thumbwheels (lower center). The timer function

(lower right) should be set at M for minutes.

6

9. TEMPERATURE CONTROLLER provides a

readout of the booth internal temperature and current

set-point (one for spray and one, or three for bake

depending on controller option). Some units will

have a dial indicators i.e. model 99270 heater.

10. EXHAUST FAN PILOT LIGHT (GREEN)

when lit indicates all is well with the exhaust motor

and the exhaust fan is running.

11. INTAKE FAN PILOT LIGHT (GREEN)

when lit indicates all is well with the intake motor

and that the intake fan is running.

12. BURNER PILOT LIGHT (GREEN) when lit

indicates power has been given to the burner

safeguard system.

13. PHOTOHELIC provides readout of interior

booth pressure and is set to maintain the cabin

pressure automatically.

DELUXE W/TOUCH SCREEN OPTION:

1. EMERGENCY (EM) STOP SWITCH, is red

in color.

2. LIGHTS ON/OFF SWITCH, located on the

touch screen, dark green when off and light green

when on.

3. OFF/SPRAY/BAKE SWITCH, located on the

touch screen. The display bar at the bottom of the

switch displays cycle of operation.

4. BURNER SUMMER/WINTER SWITCH,

located on the touch screen, on the burner window.

5. THE INTAKE LIGHT (GREEN )

OR(RED), THE EXHAUST LIGHT ( GREEN)

OR (RED), THE BURNER LIGHT (GREEN)

OR (RED). When these light are showing

(green), operation is normal. When these lights are

showing (red), an alarm is taking place.

6. HOURMETER, located on the touch screen,

records total hours of operation. The hour display

window shows spray and bake time in hours and

minutes. The hour meter is used to notify the

need for filter replacement, based on spray hours

of use.

7. BAKE TIMERS, are energized only during the

bake mode. The bake timers are located on the

touch screen in the bake timers display window.

There is a bake time count down on the main

screen of the touch screen.

8. TEMPERATURE CONTROL, is located on

the touch screen, on the burner display window

and provides a readout of the booth internal

temperature and current set-point (one for spray

and three for bake.

9. CABIN PRESSURE, cabin pressure is

displayed on the main screen of the touch screen. It

provides readout of interior booth pressure and is

set to maintain the cabin pressure automatically or

manually from the maintenance display screen.

MAIN ELECTRICAL PANEL

The control panel is fully described in the

maintenance section of this manual.

The control panel is mounted to the side of the

intake plenum near the booth front. It is white in

color and contains the power and operational

controls for the booth.

WARNING: THE MAIN ELECTRICAL

PANEL IS SUPPLIED BY TWO SOURCES

OF ELECTRICAL POWER. INSURE BOTH

SOURCES ARE DISCONNECTED BEFORE

7

ANY ADJUSTMENTS IN THE PANEL ARE

MADE.

The purge timer is an internal function of the PLC

(Programmable Logic Controller) and is adjustable

in minutes. This timer should not be set any lower

than 3 minutes according to national codes. Consult

your paint supplier or manufacturer for

recommended flash-off time.

The bake timers are an internal function of the PLC

and are adjustable in minutes. Consult your paint

supplier or manufacturer for recommended bake

times.

The cool down timer is an internal function of the

PLC (Programmable Logic Controller) and is

adjustable in minutes. Generally this timer is set a

maximum of 10 minutes. This allows the operator to

set the paint booth to bake mode and go home in the

evening. The booth will complete the bake cycle,

cool down for 10 minutes, and then shut down

completely. The Off/Spray/Bake switch will need to

be set to the Off position to allow the booth to

operate after the system has gone through a cool

down cycle and shut off automatically.

Adjustment of the purge, bake, and cool down cycles

are made with the FTX handheld unit by a qualified

technician. These time sequences are internal of the

PLC.

When using the Touch Screen option adjustment of

the purge, bake, and cool down cycles can be made

from the bake timer display screen. There is also a

recipe settings display screen accessed from the

maintenance display screen. Complete setups for

spray and bake temperatures and purge, bake, and

cool down times can be set with a touch of a recipe

button.

``REMOVING THE CAR

Review the instructions for entering the booth. Heed

the warnings for the style of booth installed.

MAINTENANCE INSTRUCTIONS

ENCLOSED PAINT BOOTH

FILTERS

To assure that the optimum-finishing environment

designed into your Garmat® Frontier Paint Booth

is maintained, filter replacement at recommended

intervals and regular cleaning of the booth and the

air-handling units is essential. Use only

recommended filters and insure that the filters are

properly installed.

The quality of finish produced by your Garmat®

paint booth is affected by the following:

a. The filter media used and the timeliness of filter

replacement.

b. The purity of compressed air used for applying

the finish. Use a quality filter and moisture trap on

compressed air lines supplying the booth. When

using a copper airline, make sure that all

connections to the equipment have di-electric

unions.

c. Spray guns and other application equipment

must be maintained perfectly clean and in proper

working order.

d. Personnel clothing (paint suits) should be

established for use only in the booth.

e. DO NOT mix paint within the booth.

f. LIMIT ACCESS to the booth.

g. DO NOT open booth doors unless the booth is

operating.

FILTER LOCATION- Two main filter groups

control the dust entering the booth and the paint

particles emitted by the booth.

EXHAUST FILTER CHANGE AT 50-60 HOUR

INTERVALS

The exhaust filters are located in the two towers

located at the back of the booth. To access the

filters rotate the access door latches, swing the

access doors open and slid the filter racks out. The

filter racks consist of two halves with one half

nested inside of the other. Separate the two halves

and remove the filter material and place in an air

tight container. Sweep and/or vacuum up all debris

8

and dust. Cut new filter material slightly larger than

the filter rack and place in the larger half of the filter

rack. Slip the smaller half of the filter rack into the

larger half. Repeat this for each filter rack and then

replace in the exhaust towers. Reset the EXHAUST

filter hours on the touch screen. Touch the word

EXHAUST filters on the touch screen to access

reset. On the filter schedule at the back of this

manual, record the date, time and hour meter

reading. Re-start the paint booth.

WARNING: USED EXHAUST FILTER

MATERIAL IS FLAMMABLE AND IS

SUSEPTIBLE TO SPONTAINOUS

COMBUSTION. DISPOSE OF PROPERLY.

CEILING FILTER CHANGE AT 1000-1200

HOUR INTERVALS

NOTE: ALTHOUGH ONE MAN CAN REPLACE

THE CEILING FILTERS, IT IS

RECOMMENDED THAT TWO PEOPLE

INSTALL THE NEW FILTERS TO INSURE

PROPER PLACEMENT. USE HAND TOOLS

ONLY.

Ceiling Filters are held in place by a removable filter

frame in the ceiling of the cabin. Filter support bolts

secure the filter frame. Rotate the support bolts clear

of the frame, insuring that the frame will not fall free,

and remove from the filter frame opening. Set filter

frame on stands. Remove the used filter media, and

thoroughly clean the filter frame with a tack rag.

Place the new filter media in the filter frame, tuck the

media into the ends of the frame, and then tuck the

media into the sides of the frame. Raise the filter

frame up into the filter frame opening. Rotate the

support bolts back into place and tighten by hand

making sure not to over tighten. Reset the ceiling

filter hours on the touch screen. Touch the word

CEILING FILTERS on the touch screen to access

reset. The FLAME ROD in the burner should be

replaced at this time.

9

MAINTENANCE SCHEDULE

DAILY

CHECK booth pressure and make sure the booth

pressure is operating in the proper range, .02 Inches

of Water Column (green in the pressure bar on the

touch screen option).

SWEEP the floor while the booth is in operation.

The booth floor may be mopped, with a well rung

out mop.

CHECK the exhaust filters.

1000-HOUR INTERVAL (ANNUALLY)

At each 1000-hour interval, the following

preventative maintenance checklist should be

reviewed. If any malfunction is found, it should be

repaired immediately.

MOTORS - Replace fan belts. Adjust for proper

tension.

NOTE: Proper tension is ½” deflection at a mid

point between the pulleys using moderate pressure.

Tension testers are available at local belt and drive

suppliers.

FANS- Check fan blade surfaces. Clean if

necessary. Oil the blade surfaces after cleaning. DO

NOT USE SILICON BASED OIL. In addition, oil

the changeover damper hinges. Some hinges will

have grease zerks.

BOOTH - Examine all door seals, replace with

Garmat approved seals only. Change ceiling filters.

Check exhaust filters and replace if necessary.

Lubricate the larger hinges provided with grease

zerks.

CAUTION: FAILURE TO PERFORM THE

REQUIRED LUBRICATION WILL CAUSE

PREMATURE FAILURE OF THIS EQUIPMENT.

The moving mechanical portions of this equipment

require regular lubrication not less than every 3

months. The items requiring regular lubrication

include and are not limited to: door hinges,

dampers, and motors. If you are unsure which

items need lubrication, contact the equipment

supplier. If extreme moisture is present, lubrication

may need to be performed weekly.

CONTROL AIR – The air supplied to the Garmat

USA, Inc. paint spray booth must be clean and dry

before the attachment to the electrical control

panel. Water separators, filtersystems for

compressed air shall be installed up stream of the

Garmat USA, Inc. main electrical control panel

and filters, desiccant…etc. should be changed

annually. Examine the regulator/filter and oilier for

the control air (located at the side of the main

control panel). Pressure should be set between 45-

60 psi, drain the filter and refill the oilier with air

tool oil.

CONTROL PANEL - Review the following:

a: Pressure settings.

b: Temperature settings

Touch screen option

a: Touch screen cover (peel away).

b: Touch screen operation.

FINALLY - Run the booth a complete cycle of

operation and observe all functions.

AS RECOMENDED

MOTORS - In general, the motors supplied with

your Garmat paint booth require lubrication and

are fitted with grease zerks. Lubricate the motor

with a good quality grease quarterly making sure

not to force grease into the bearings. A ¼ squeeze

on a normal hand pump grease gun is sufficient.

Forcing grease into the bearing will damage the

bearing seals and shorten the motor life.

HEATER SECTION- Gas fired heaters require

little or no maintenance. However the burner

manifold should be inspected to make sure there is

no build up of debris or moisture. The flame rod in

10

the burner manifold should be replaced Annually.

Also the burner manifold should be completely

cleaned out every Four Years by a qualified service

technician.

MAINTENANCE OF INTERNAL AND

EXTERNAL SURFACES

To clean, use a soft, dry cloth. If the surfaces are

extremely dirty, use a soft cloth, dipped into a soap

and water solution or a weak detergent solution.

Wring the cloth before wiping the surface. Wipe

again with a soft, dry cloth.

Never use alcohol, paint thinner, benzine, nor a

chemically treated cloth to clean this equipment.

Such chemicals may damage the finish of your

booth. Never pressure wash or hose down the

interior or exterior of the booth, electrical shorts or

shocks can occur. In addition, water will collect in

light fixtures and various components of the booth

cabin and rust deterioration will begin.

PRESSURE WASHING WILL VOID YOUR

WARRANTY.

11

TROUBLESHOOTING

OPERATOR TROUBLESHOOTING CHART

SYMPTOM POSSIBLE CAUSE(S) ACTION

RECOMMENDED

NOTHING WORKS. EM switch is off. Incoming 3 phase voltage Turn EM switch on. Check incoming 3

(TOUCH SCREEN DARK) is off. The 110-v control breaker in main phase breaker at wall panel. Reset breaker

control panel is tripped. in main control panel.

NOTHING WORKS. Overload relay is tripped. Loss of a phase. Reset overload relay. Check for 3 phase.

(TOUCH SCREEN ON AND Low 3 phase voltage. Measure motor amps. Measure 3 phase

A RED MOTOR LIGHT IS ON). voltage.

EVERYTHING WORKS Lighting breaker(s) are tripped. Reset lighting breaker(s). Check change-

BUT BOOTH LIGHTS. over damper.

TEMPERATURE DOES NOT Outside air temperature is greater than set- Increase set point temperature on

RISE. (BURNER GREEN LIGHT point temperature. Temperature controller. Booth temperature

IS ON). will not exceed 190°F

TEMPERATURE DOES NOT Pilot has failed during fire cycle. Push reset button on red enclosure

RISE. (BURNER RED LIGHT Pilot manual gas valve turned off. marked FIREYE. Turn manual valve ON.

IS ON). High limit, low gas and/or high gas If lockout repeats, call a Garmat USA

pressure switch tripped. proof of closure authorized service-technician. Touch alarm

Open. on screen and follow instructions.

TEMPERATURE TOO HIGH Controller is set to Bake or second Set- Outside temperature above 70°F. Press the

DURING SPRAY MODE. Point. Moni/Mode button and press the up arrow to

Put the control into AUTO mode, press

Moni/Mode button to go back top the

normal display. Set SUMMER/WINTER

switch to SUMMER.

OPERATION SEQUENCE

This section is provided to assist a service technician

and explain in detail what is happening during

“normal” operation.

SPRAY/BAKE BOOTH OPERATION

The spray/bake booth has four separate modes of

operation: POWER ON, SPRAY, BAKE, and

SHUTDOWN.

POWER ON:

The green light marked POWER is lit when

the booth is in POWER ON mode. The 110v

and 24v control voltages are provided from the

secondary side of the control transformer. The

primary side of the control transformer is

connected to the incoming three-phase motor

voltage supply.

The 120v is connected through a jumper

connection provided for use with a NC contact

on an alternative fire suppression system that

12

requires shutdown of the booth fans. Breaking the

circuit at that point will shut down all booth

operations. The 120v continues through the EM

(emergency) stop switch in the remote control panel,

and NC overload contacts of each Motor Starter. The

120v is then present at the light switch,

off/spray/bake switch, and bake timer. If either

motor trips to an overload condition, a RED light for

the respective motor is lit, and all booth operations

quit. Breakers protect both control voltages, 110v

and 24v.

The EM switch, when depressed, shuts down all

both operations. Turning the EM switch clockwise

reconnects the supply voltage, unless the jumper

circuit for the fire suppression system is open.

SPRAY MODE:

When the green power light is lit, placing the OFF-

SPRAY-BAKE switch in the spray position begins

the Spray Mode. The booth will operate in SPRAY

mode indefinitely. The operator must shut off the

booth, or switch to the Bake Mode. The SPRAY

position provides 120v to the PLC (Programmable

Logic Controller) and shows input “0” on the PLC

input display. This in turn provides 110v to starter

SM2 located in the Control Panel. SM2 controls the

Exhaust Motor and shows as “10” on the PLC output

display. The green light for the exhaust motor on the

Control Panel should be lit. A time sequence is also

started in the PLC as SM2 is energized. At the end of

the time sequence, 110v power is provided to SM1

and the Temperature Controller and shows as “9” on

the PLC output display. SM1 controls the intake

motor and provides 120v to the green light for the

intake motor and the BURNER switch. The

temperature controller should show display and go

through its’ boot operations. All are located on the

remote control panel.

If the BURNER switch is in the WINTER position,

120v power is provided to the PLC and shows as “3”

on the PLC input display, which in turn provides

110v to the gas train power circuit shown as “7” on

the PLC output display. See the text of the Gas

Train Power Circuit. If the BURNER switch is in

the SUMMER position, the Gas Train Power

Circuit will not be energized as there will be

no input to the PLC.

BAKE MODE:

Place the OFF-SPRAY-BAKE switch in

BAKE provides 120v to the PLC and shows as

“1” on the PLC input display. The PLC will

perform a time sequence then power is applied

to the Bake Timer located on the Remote

Control Panel, the change over damper

solenoid and relay RP in the main control

panel. This places the booth in Bake Mode.

The timer will begin timing. The Bake Timer

should be set in its’ “C” mode, on the left of

the timer face, and “M” for minutes, on the

right.

When the Change over damper solenoid is

energized, the changeover damper is opened

pneumatically releasing the Damper Position

Valve. When released, the pressure switch

(RA) connected to the Position Valve de-

energizes input to the PLC shown as “11” on

the PLC input display. This disconnects 110v

power to the compressed air solenoid, shown

as “5” on the PLC output display, and

eliminates the 120v circuit to RL contactor,

turning off the booth lighting. If the burner

switch is in the summer position, the PLC will

give 120v to the gas train circuit. The (RP)

relay closes the second set point loop on the

temperature controller. This sets the

temperature controller to the second set point

or starts the sequence of multiple temperature

settings on a multi-set point controller

(optional).

At the completion of the bake time, the Bake

Timer stops timing and gives 120v input to the

PLC shown as 14 on the PLC input display.

This begins the Cool Down time sequence

(Shutdown mode).

SHUTDOWN MODE:

13

The Bake Timer directs 120v power to then PLC and

shows as 14 on the input display in the Main Control

Panel, beginning the Shutdown mode. The power to

the changeover damper solenoid and RP relay are

interrupted. The changeover damper closes, RA are

energized, the booth lights come back on, and the

Temperature Controller returns to set point, SP, also

known as the Spray Temperature. The output from

the PLC will be de-energized shutting off the burner

if the OFF-SPRAY-BAKE switch is set to summer

position.

The PLC also begins and internal time cycle,

normally 10 minutes, all functions of the booth will

shut down completely at the end of the time cycle.

The logic of the PLC will not allow the booth to

restart until the OFF-SPRAY-BAKE switch is set to

the OFF position. The Operator may interrupt the

Shutdown Mode at any time by placing the OFF-

SPRAY-BAKE switch in the SPRAY position.

GAS TRAIN POWER CIRCUIT:

When the burner switch is set to the winter position

there will be input to terminal 4 of the PLC and will

show number 3 on the input display of the PLC. The

PLC checks to make sure that the input is at 0 on the

input display and outputs to 7 on the output display,

giving power to the low gas pressure switch. The

PLC then makes a scan of the input to 4,5, 6 & 7, on

the input screen, and then gives output to 12 on the

output display, giving power to the Fireye unit and

power to 1 on the output display giving power to the

burner green light. The PLC will have input at 8 on

the input display, showing power to the airflow

switch. When the Fireye has done its’ job there

should be power to 9 on the input screen, showing

that power has been given to the vent and blocking

valves on the gas train. The PLC will also make the

signal connection 0 on the output display, making

the connection between the gas modulating valve

and the temperature control. In the event the Fireye

goes into the alarm state, there will be input to 10 on

the input display and no input to 9 on the PLC input

display. There will also be output to 2 on the output

display, giving power to the burner red light and the

output to 1 on the display, discontinuing the

power to the burner green light.

The Low Gas and High Gas Limit, the Proof

of Closure switch (all three are located on the

gas train), the High Temperature switch

(located on the roof of the cabin) or the Air

Flow switch (Intake Pressure switch). Each of

these items may be checked by proving 110

volts from their respective terminals at the top

of the Main Control Panel. The airflow switch

(intake pressure switch) is powered through

the flame safety module, and has two

terminals.

The flame safety module will give an alarm

state (lighting the red burner light) for one of

three reasons. One, there is no spark in the

burner to ignite the burner pilot. Two, there is

no fuel being delivered to the pilot to create a

flame. Three, the flame guard device is not

sensing that there is flame in the burner.

COMPRESSED AIR FOR SPRAY

APPLICATIONS WITHIN BOOTH:

A solenoid is provided to control compressed

air in the booth. It is located within the Main

Control Panel. 110v power is provided to the

solenoid through the PLC output 5 on the

display. For the PLC to output at 5, the RA air

over electric switch, Door air switch, and

exhaust pressure switch must be closed giving

power to the PLC input 12.

14

This section is provided to assist a service technician

and explain in detail what is happening during

“normal” operation of a booth with a Touch Screen

option.

SPRAY/BAKE BOOTH OPERATION

The spray/bake booth has five separate modes of

operation: POWER ON, SPRAY, BAKE, COOL

DOWN and SHUTDOWN.

POWER ON:

The touch screen display is on when the booth is in

POWER ON mode. The 110v and 24v control

voltages are provided from the secondary side of the

control transformer. The primary side of the control

transformer is connected to the incoming three-phase

motor voltage supply.

The 120v is connected through a jumper connection

provided for use with a NC contact on an alternative

fire suppression system that requires shutdown of the

booth fans. Breaking the circuit at that point will shut

down all booth operations. The 120v continues

through the EM (emergency) stop switch in the

remote control panel, and NC overload contacts of

each Motor Starter. The 120v is then present at the

light switch, the programmable logic controller

(PLC) and the touch screen. If either motor trips to

an overload condition, a RED light on the touch

screen for the respective motor is lit, and all booth

operations quit. Breakers protect both control

voltages, 110v and 24v.

The EM switch, when depressed, shuts down all

booth operations. Turning the EM switch clockwise

reconnects the supply voltage, unless the

jumper circuit for the fire suppression system

is open.

SPRAY MODE:

When the touch screen is displayed, touching

the word SPRAY will put the controls in the

Spray Mode. The booth will operate in

SPRAY mode indefinitely until the operator

shuts off the booth, or switches to the Bake

Mode. The SPRAY mode provides 120v to

the PLC (Programmable Logic Controller) and

shows input “0” on the PLC input display.

This in turn provides 110v to starter SM2

located in the Control Panel. SM2 controls the

Exhaust Fan Motor and shows as “10” on the

PLC output display. The indicator light for the

exhaust fan motor on the Touch Screen should

be green. A time sequence is also started in the

PLC as SM2 is energized. At the end of the

time sequence, 110v power is provided to the

temperature controls and starter SM1, located

in the Control Panel. SM1 controls the Intake

Fan Motor and shows as “9” on the PLC

output display. The indicator light for the

intake fan motor on the Touch Screen should

be green. SM1 provides 120v to the burner

control circuit. The touch screen will show the

booth temperature and the controls should go

through the boot operations.

If the BURNER switch is in the WINTER

position, 120v power is provided to the PLC

and shows as “3” on the PLC input display,

which in turn provides 110v to the gas train

power circuit shown as “7” on the PLC output

display. See the text of the Gas Train Power

Circuit. If the BURNER switch is in the

SUMMER position, the Gas Train Power

Circuit will not be energized as there will be

no input to the PLC.

BAKE MODE:

Touching the word BAKE on the touch screen

begins the Bake Mode and provides 120v to

15

the PLC and shows as “1” on the PLC input display.

The PLC will perform a purge time sequence, during

which the booth will remain in the spray mode

temperature. At the end of the purge cycle the PLC

will begin timing the Bake Cycle and energize the

Changeover damper solenoid in the main control

panel. This places the booth in Bake Mode.

When the Changeover damper solenoid is energized,

the Changeover damper is pneumatically opened,

releasing the Damper Position Valve. When the

Damper Position Valve is released, the pressure

switch (RA), connected to the Damper Position

Valve, de-energizes and input is given to the PLC,

shown as “11” on the PLC input display. This

disconnects 110v power to the compressed air

solenoid, shown as “5” on the PLC output display,

and eliminates the 120v circuit to RL contactor,

turning off the booth lighting. If the burner switch is

in the SUMMER position, the PLC will give 120v to

the Gas Train Power Circuit, shown as “7” on the

PLC output display. In WINTER position the Gas

Train Power Circuit will already have 120v power.

The controls then initiate the ramp up time and

temperature. This begins the sequence of multiple

time and temperature settings.

At the completion of the bake time, the PLC stops

the bake time sequence and begins the Cool Down

time sequence (Shutdown mode).

SHUTDOWN MODE:

The power to the Changeover damper solenoid and

RP relay is interrupted. The Changeover damper

closes, RA is energized, the booth lights come back

on, and the booth temperature returns to the Spray

Temperature. The output from the PLC will be de-

energized, shutting off the burner if the Burner

switch on the touch screen display is set to

SUMMER position. If the Burner switch is set to

WINTER position, the burner circuit will remain

energized.

The PLC also begins and internal time cycle,

normally 10 minutes. All functions of the booth will

shut down completely at the end of the time

cycle. After the time cycle is complete, the

logic of the PLC will not allow the booth to

restart until the OFF-SPRAY-BAKE switch,

displayed on the touch screen, is set to the OFF

position. The Operator may interrupt the

Shutdown Mode at any time before the time

cycle is complete, by placing the OFF-

SPRAY-BAKE switch in the SPRAY

position.

GAS TRAIN POWER CIRCUIT:

When the BURNER switch (on the touch

screen display) is set to the WINTER position

there will be input to terminal 4 of the PLC and

will show number “3” on the input display of

the PLC. The PLC checks to make sure that

the input is at “0” on the input display and

outputs to “7” on the output display, giving

power to the low gas pressure switch. The PLC

then makes a scan of the input to “4,5, 6 & 7”,

on the input screen, and then gives output to

“11” on the output display, giving power to the

Fireye unit and power to “1” on the output

display giving power to the burner green light.

The PLC will have input at “8” on the input

display, showing power to the airflow switch.

When the Fireye has done its’ job there should

be power to “9” on the input screen, showing

that power has been given to the vent and

blocking valves on the gas train. The PLC will

also make the signal connection “0” on the

output display, making the connection between

the gas modulating valve and the temperature

controls. In the event the Fireye goes into the

alarm state, there will be input to “10” on the

input display and no input to “9” on the PLC

input display. There will also be output to “2”

on the output display, giving power to the

burner red light, and discontinuing the power

to the burner green light, output to “1” on the

display,.

The Low Gas and High Gas Limit, the Proof

of Closure switch (all three are located on the

16

gas train), the High Temperature switch (located on

the roof of the cabin) or the Air Flow switch (Intake

Pressure switch). Each of these items may be

checked by proving 110 volts from their respective

terminals at the top of the Main Control Panel. The

airflow switch (intake pressure switch) is powered

through the flame safety module, and has two

terminals.

The flame safety module will give an alarm state

(lighting the red burner light on the touch screen

display) for one of three reasons. One, there is no

spark in the burner to ignite the burner pilot. Two,

there is no fuel being delivered to the pilot to create a

flame. Three, the flame guard device is not sensing

that there is flame in the burner.

COMPRESSED AIR FOR SPRAY

APPLICATIONS WITHIN BOOTH:

A solenoid is provided to control compressed air in

the booth. It is located within the Main Control

Panel. 110v power is provided to the solenoid

through the PLC output “5” on the display. For the

PLC to output at “5”, the RA air over electric switch,

Door Air switch, and Exhaust Pressure switch must

be closed giving power to the PLC input “12”.

17

CEILING 1000

/

INTAKE 1000

/

EXHAUST 1000

/

EXHAUST 950

/

EXHAUST 900

/

EXHAUST 850

/

EXHAUST 800

/

EXT & INT 750

/

EXHAUST 700

/

EXHAUST 650

/

EXHAUST 600

/

EXHAUST 550

/

EXT & INT 500

/

EXHAUST 450

/

EXHAUST 400

/

EXHAUST

3

50

/

EXHAUST

3

00

/

EXT & INT 250

/

EXHAUST 200

/

EXHAUST 150

/

EXHAUST 100

/

EXHAUST 50/

COMMENTS

SPEC/ACTUAL

FILTER HOURS DATE

18

Table of contents

Other Garmat Service Equipment manuals