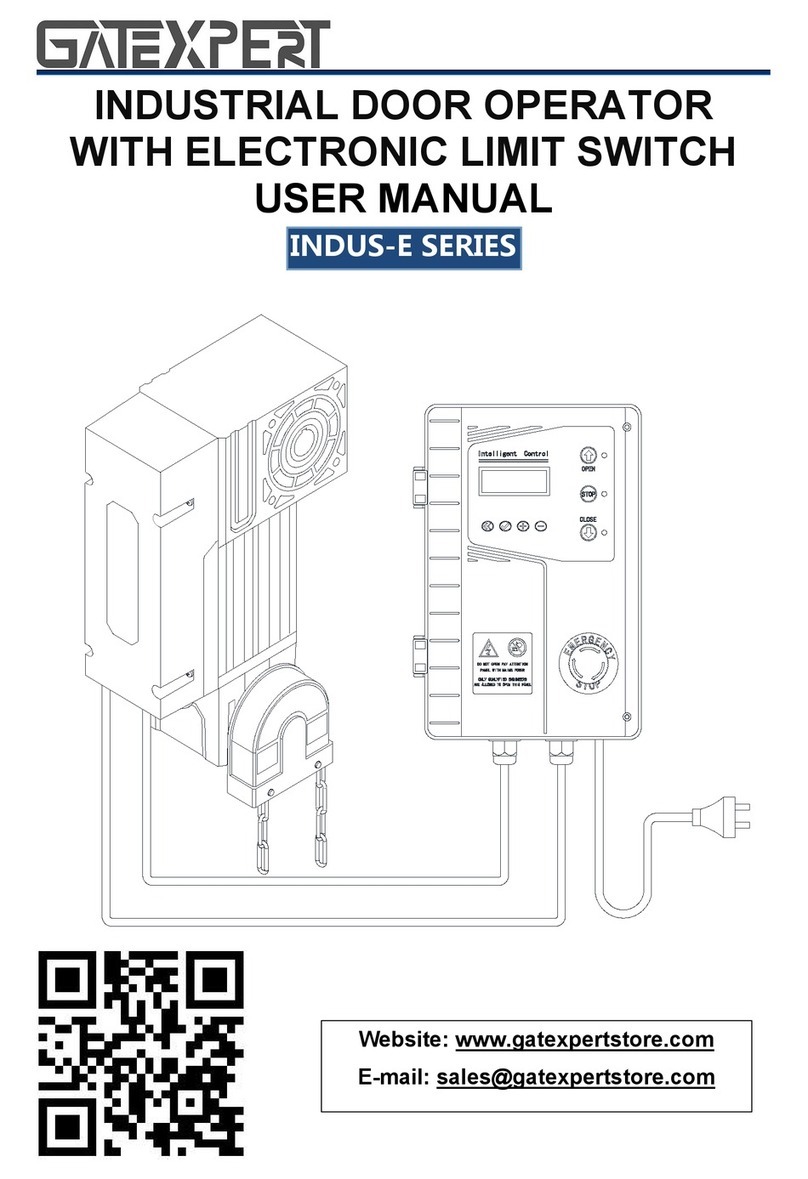

GATEXPERT GK Series User manual

INDUSTRIAL DOOR OPERATOR

USER MANUAL

GK SERIES

Website: www.gatexpertstore.com

E-mail: sales@gatexpertstore.com

Instructions for GK SERIES

www.gatexpertstore.com

WARRANTY

1. To repair against this warranty card and invoice during the warranty period.

2. Warranty period: 1 year after the date of invoice.

3. Without unauthorized dismantling, any product broken or damage due to quality

problem, we’ll offer the repair service for free or replace for free.

4. The malfunction and damages caused by incorrect use or man fault is not covered by

this warranty.

CONTACT US

E-mail: sales@gatexpertstore.com

Please fill in the order information in the form below.

All personal information you provided will be only used for warranty service and kept

strictly confidential.

Refer to this list when contacting GATEXPERT for technical service or assistance with

your automatic gate opener.

Order Number

Product Model

Purchase Date

Country / Region

Email Address

Issue Details

Instructions for GK SERIES

www.gatexpertstore.com

Dear users,

Thank you for choosing this product. Please read the manual carefully before assembling

and using it. Please do not leave out the manual if you send this product to a third party.

Safety Instruction

1. The industrial door operator should be installed and put into operation by qualified

personnel. Otherwise, serious personal injury or property damage may occur.

2. Installation and wiring must be in accordance with the construction standards and

electrical standards, diameter ≧1.5mm2; power must have a reliable grounding, ground

wire must be reliably connected to the place labeled ground tab, ground lead on the

power line is prohibited to be removed; front end of incoming power line should be

installed with electrical leakage protector which is in line with national standards.

3. This industrial door operator is only allowed to be installed on well-balanced door

which has balance spring, otherwise machine may be damaged due to overload.

4. Door should be flexible and run without stagnation; lead rail end of door must be

installed with mechanical stop block and buffering booster to prevent the door from rolling

out.

5. Control box should be installed in the wall or column of 1.4 meters where the operation

of door can be observed to prevent children from inadvertently touching. While keeping

the remote control, prohibit children to touch or play just in case of danger. Do not use the

remote control when you cannot see the operation of door.

6. Before repairing and moving the door machine and control box, please cut off the

power supply, and make sure that the door has been locked and the risk of falling due to

self-weight is null.

7. Pedestrian and vehicle are prohibited to go through or stay below the running door.

8. Hand-pulled chain on the machine is prohibited to be pulled during the operation of

door machine to prevent the machine from damage.

9. To ensure the safety of pedestrian and vehicle, please install the infrared protection

device and airbag protection device

10. Relevant safety protection devices and the operation of the door should be checked

frequently to ensure the security and stability of door.

Instructions for GK SERIES

www.gatexpertstore.com

CONTENTS

1. Technical Parameter Table……….……………………………...…………….……1

2. Dimension and Component of Industrial Door Operator…............……3

3. Installation Guide of Industrial Door Operator ……….......…………...……4

4. Industrial Door Operator Wiring……………………....………………..…..…... 7

5. GK220 Control Panel Wiring (AC220V) ………….…….………….……….. 8

6. GK380 Control Panel Wiring (AC380V) ………..……….………….……….. 9

7. Usage of hand-pulled chain … ………...………....……………………………..10

8. Setting and Adjustment of Limit……………....……………………………..11

9. Fitting Wiring……………....................................……………………………..12

10. Setting and Debugging of Control Box…………………...….………....…..14

11. Common Faults and Countermeasures ..................................................16

12. Packing List…………...............…………………………...…………………..……18

Instructions for GK SERIES

www.gatexpertstore.com

1

Industrial Door Operator Technical Parameter

Model (Single Phase AC220V±10%)

GK40

GK60

GK100

Rated Power

300W

400W

550W

Torque

40N.m

60N.m

100N.m

No-load Continuous Running Time

15min

8min

Model (Three Phase AC380V±10%)

GK60S

GK100S

GK150S

Rated Power

400W

550W

750W

Torque

60N.m

100N.m

150N.m

No-load Continuous Running Time

15 min

Other Parameter Characteristics of Above Industrial Door Operator

Thermal Protection Temperature

120℃

Reduction Ratio

1:58

No-load Rotation Speed

24r/min

Lubricating System

Oil-immersed

Noise

≤55dB

Hand Release Device

Hand-pulled chain

Quick Release

Optional

Maximum Limit Travel

Output shaft rotates 20 rounds

Output Shaft Diameter

Φ25.4mm

Environment Temperature

-20℃~+45℃

Working Duty

S2-15min

Protection Class

IP54

Main engine Dimension

218x135x357 mm.

Main engine Weight

12.5Kg

Control Unit Technical Parameter

Model

GK220

GK380

Power Supply

AC220V/50Hz

AC380V/50Hz

Remote Control Model

RT01

RT01

Applicable Model

GK40/60/100

GK60S/100S/150S

External Three Button Switch

Available (Optional)

Available (Optional)

Protection Class

IP54

IP54

Alarm Lamp

Available (Optional)

Available (Optional)

Infrared Sensor

Available (Optional)

Available (Optional)

Power Lock

Available (Optional)

Available (Optional)

Airbag Switch

Available (Optional)

Available (Optional)

Instructions for GK SERIES

www.gatexpertstore.com

2

Loop Detector (Sense Coil)

Available (Optional)

Available (Optional)

Instructions for GK SERIES

www.gatexpertstore.com

3

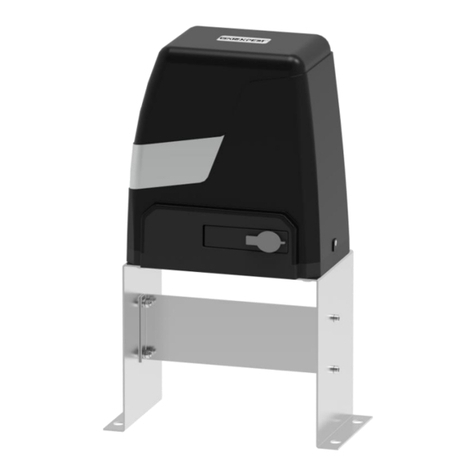

Dimension and Component of Industrial Door Operator

①Gearbox

②Mechanical limit cam

③Terminals

④Plastic cover

⑤Motor

⑥Hand-pulled chain

⑦Pull cord switch

Instructions for GK SERIES

www.gatexpertstore.com

4

Installation Guide of Industrial Door Operator

The industrial door operator is mainly used in the industrial sectional door equipped with

balance spring, but also can applied in lifting industrial door. The installation of door

machine has two forms, shaft drive and chain drive. The factory standard configuration is

shaft drive. If user want to adopt chain drive installation, they can choose the appropriate

combination of sprocket chain according to the installation needs.

Shaft Drive Installation Chain Drive Installation

1) Check the door

After the door is installed, adjust the torsion spring, manually opening or closing the door

should be flexible and run without stagnation, observe the direction of rotation of the rope

sheave which should be consistent with the direction of opening and closing of industrial

door operator.

Shaft Drive Installation

Chain Drive Installation

1Expansion Screw

1Driven wheel

②Mounting Bracket

②Door Shaft

③Mounting Screw

③Chain

④Main Engine

④Mounting Bracket

⑤Special Flat Key

⑤Driving Sprocket

⑥Door Shaft

⑥Driving Sprocket Shaft

⑦Fixing Sleeve

⑦Main Engine

Instructions for GK SERIES

www.gatexpertstore.com

5

2) Determine the installation position

Consider the boundary dimension and installation direction of the door machine,

determine the position of the mounting bracket, mark the insert cavity position, drill the

screw hole and fix the mounting bracket. (The mounting bracket can be fixed inside and

outside the door machine, recommended to be installed inside, for the convenience of

disassembly of door machine).

3)Try to install industrial door operator

Install a fixing sleeve on door shaft in advance, and insert the industrial door operator into

the door shaft.

4) Pre-fixing industrial door operator

Fix the industrial door operator on mounting bracket by 4 pieces of hexagon head flange

bolts M10×20, do not tighten.

Instructions for GK SERIES

www.gatexpertstore.com

6

5) Find the direction of key slot

First pull the red handle A to the bottom to make the hand-pulled chain mechanism enga

ge with the main engine (Manual control mode).

Rotate the output shaft of industrial door operator by pulling the hand-pulled chain up and

down until the key slot of the output shaft is fully aligned with the key slot of the door

shaft.

6) Mount flat key and fixing sleeve

Mount the flat key, keep two fixing sleeves close to the two ends of the output shaft,

fasten the two M6 head screws in the key slot of door shaft in order to prevent the flat key

from loosening and falling off.

7) Tighten the screws, prepare wiring and debugging Tighten all screws.

Finally pull green handle B to the bottom to make the hand-pulled chain mechanism deta

ch from the main machine (Electric control mode).

Instructions for GK SERIES

www.gatexpertstore.com

7

UVWCL CO OP NC CO NO

A

B

1

2

3

4

5

6

7

UVWCL CO OP NC CO NO

UVWCL CO OP

Industrial Door Operator Wiring

Pull the cable through the waterproof connector on the main engine, connect it with the

terminal inside the industrial door operator according to the instruction of cable marker.

A: Thermal Protection Wire B: Motor Wire

①Limit Switch

②Terminals

③Motor Thermal Protection Wire White

④Cable CL Red, CO White, OP Green.

⑤Output Passive Signal Wire of Opening Door, NC Yellow, CO Pink, NO Purple

⑥Motor Wire U Blue, V Brown, W Black

⑦Protection Switch of Hand-Pulled Chain (N.O.)

Instructions for GK SERIES

www.gatexpertstore.com

8

OP

COPTDET

CO

CL

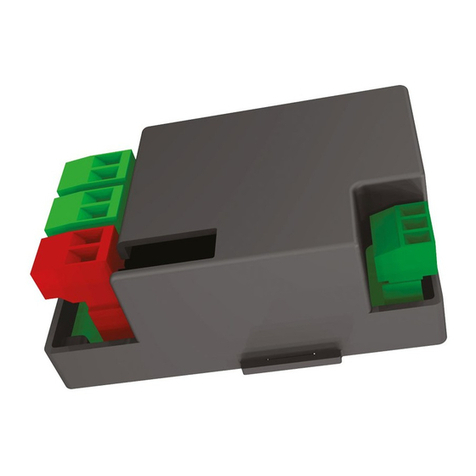

GK220 Control Panel Wiring (AC220V)

Wiring of power, motor and limit switch of GK40, GK60, and GK100 single phase control box as shown below

①Single Phase Power Wire L, N ②Motor Wire (U BLUE, V BROWN, W BLACK) ③Capacitor Wire (C BLUE, C BROWN)

④Grounded Wire (E YELLOW GREEN double color) ⑤Close Limit Wire (CL RED)

⑥Limit Common Wire (CO WHITE) ⑦Open Limit Wire (OP GREEN)

Note: Make sure the wires are securely connected. After the wiring is completed, please tighten the waterproof connector, so that the

wire is completely fixed.

WARNING: When connecting the power wires, be sure power is off so as to avoid electric shock!

Instructions for GK SERIES

www.gatexpertstore.com

9

OP

COPTDET

CO

CL

GK380 Control Panel Wiring (AC 380V)

Wiring of power, motor and limit of GK60S, GK100S and GK150S three phase control box as shown below

①Three Phase Power Wire L1, L2, L3 ②Power Neutral Wire N ③Motor Wire (U RED, V WHITE, W BLACK)

④Grounded Wire (E YELLOW GRENN double color) ⑤LED2 Indicator Light ⑥Close Limit Wire (CL RED)

⑦Limit Common Wire (CO WHITE) ⑧Open Limit Wire (OP GREEN)

Note: 1. Make sure the wires are securely connected. After the wiring is completed, please tighten the waterproof connector, so that the

wire is completely fixed.

2. If re-wiring, change in phase sequence which may cause the machine reverse should be avoided. Under the correct condition

of phase sequence, LED2 indicator light should be off rather than flashing.

WARNING: When connecting the power line, be sure power is off so as to avoid electric shock!

Instructions for GK SERIES

www.gatexpertstore.com

10

Usage of hand-pulled chain

When you need to manually open or close the industrial door, then hand-pulled chain

would be required.

Before pulling the chain, please fully pull the red handle A in the hand-pulled chain

mechanism to make it engage with the main machine. The protection switch inside the

hand-pulled chain mechanism will automatically cut off the power supply. At this time,

the chain can be pulled.

The chain should be pulled continuously and evenly to avoid damage to the

hand-pulled chain mechanism.

When you need to electrically open or close the industrial door, please fully pull the

green handle B in the hand-pulled mechanism first to make it disengage from the

main machine, and the protection switch in the hand- pulled mechanism will be reset

to make the industrial door operator return to its normal electric operation. Please fix

the hand-pulled chain on the wall properly when it’s not in use

Note: 1. After using the chain. If the display screen on the control unit shows it

is hand-pulled chain operation, then under which the door cannot be opened or

closed electrically, because the protection switch inside the hand-pulled chain

mechanism has not been reset. To fully pull the green handle in the hand-pulled

chain mechanism to separate it from the main machine, the control unit will

work normally until the hand-pulled chain operation is not shown any more on

the display screen

2. The hand-pulled chain can only be used in special circumstances such as

power failure. It cannot be used long term as normal state.

Note: Check once a month whether the travel of opening or closing is changed,

whether the limit position is accurate and reliable, whether the door is well

balanced, if not, please make adjustment timely.

If necessary, please ask professional personnel for maintenance and

debugging.

Instructions for GK SERIES

www.gatexpertstore.com

11

1

2

3

4

5

6

7

8

9

10

Setting and Adjustment of Limit

Limit Switch Structure:

①Passive Signal Cam (GREEN)

② ③ Open Limit Cam (GREEN)

④ ⑤ Close Limit Cam (RED)

⑥Passive Signal Micro switch

⑦ ⑧ Open Signal Micro switch (N.C.)

⑨ ⑩ Close Signal Micro switch (N.C.)

1) Close Limit Setting

Electronically close the door to the close limit position, and press the "STOP" button

on the control box to stop the

door. During the closing of door,

observe the rotation direction of

red cam on the limit gear (see below).

After the door is stopped, make

the two red cams continue to rotate

in this direction by hand until

both red cams pin down the limit

switch, which will make cracking sounds,

and then tighten the head screw in the middle of copper nut by hex wrench to fix two

red cams.

2) Open Limit Setting

With the same way of close limit setting, fix the two green cams of open limit to the

desired open limit position.

3) Precise Adjustment of Limit

Test the industrial door operator. If open or close limit position is not ideal, open or close limit

can be adjusted precisely.

a. Precise Adjustment of Close Limit:

Rotate the micrometer adjusting screw of

two red cams clockwise or counterclockwise

(as shown in the right), and observe the

direction of movement of the cam. When

the direction of movement is consistent

Instructions for GK SERIES

www.gatexpertstore.com

12

DET

CO

PT

OP

CO

CL

NO

NOCONC

GND24V5VOPNCLSSTPCOMDET

CO

PT

OP

CO

CL

NO

24V24VOUTCOM

24V

with the original cam rotation direction,

the close limit switch moves up and the close position will be higher. Otherwise

close position will be lower; under normal circumstances, if the hex wrench is rotated

90 °, the close position will differ by around 25mm.

b. Precise Adjustment of Open Limit: With the same way, rotate the micrometer

adjusting screw of two green cams until the desired open limit position is reached.

Note:

1) During debugging of door operator, please use the buttons on the control

box for operation.

2) Test several times to ensure the normal opening or closing of door, and

control box should be installed in the wall or column of 1.4 meters where the

operation of door can be observed, and to prevent children from inadvertently

touching.

Fittings Wiring

1. The signal wire of infrared sensor should be connected with PT and CO (State as

delivered is N.O.), power with "24V" and GND";

2. Airbag switch should be connected with PT and CO (State as delivered is N.O.)

Instructions for GK SERIES

www.gatexpertstore.com

13

GND24V5VOPNCLSSTPCOM

NO

开

停

关

DET

CO

PT

OP

CO

CL

3. The door in door switch is wired with "DET" and "CO" (State as delivered is N.C.).

When connect the door in door switch, please remove the short circuit wire jumper

between "DET" and "CO".

4. External three button switch should be connected with OPN, CLS, STP, COM

(State as delivered is N.O.). Open control wire with OPN; Close control wire with CLS;

Stop control wire STP; COM is common wire.

5. AC220V alarm lamp can be connected with D1, D2.

Instructions for GK SERIES

www.gatexpertstore.com

14

LED2AN1

Setting and Debugging of Control Box

After confirming the wiring, turn on the power for the debugging of next step (the

following debugging steps can be applied to both single phase and three phases

control box):

a. Remote control learning:

①Press the black button AN1 on the circuit

board, LED2 indicator light flickers, then

press any button of transmitter (usually

Button 1), LED2 indicator light flickers again,

and then press the same button of transmitter,

LED2 indicator light will be strobe for 4 seconds and later off. The learning of the

remote control is finished.

②As for the learning of the other remote control, repeat the above steps. The same

control panel can learn up to 25 remote controls.

③There are two modes for remote control: Three Button Mode and Single

Button Mode. Please decide one of the two modes mode when ordering.

Three button mode remote control: OPEN/CLOSE/STOP of main engine are controlled by

three buttons separately on the remote control.

Single button mode remote control: OPEN/ STOP/CLOSE of main engine are controlled by

one button circularly on the remote control.

Note:

Three button mode remote control: As long as the "Button 1" is learnt, the entire remote

control learning can be completed.

Single button mode remote control:The four buttons on the remote control can be paired

to four different motors, each button for one motor.

Instructions for GK SERIES

www.gatexpertstore.com

15

1 2 3

ON

OFF

1 2 3

ON

OFF

1 2 3

ON

OFF

DIP Switch

DIP Switch

DIP Switch

12 3

ON

OFF

12 3

ON

OFF

12 3

ON

OFF

DIP Switch

DIP Switch

DIP Switch

b. Delete remote control:

Delete remote control that have been learned; press the learning button AN1 and

indicator light will be on; loosen the button until LED2 is off. This indicates that all

remote controls that learned previously have been deleted.

Note: Users are suggested to delete the original remote controls and

re-learning them before the formal use in favor of security.

c. DIP switch selection:

By setting the DIP switch to set the required functions

(See fig. below):

Automatic close function Enable Automatic close function Disable

Inch moving Continuously moving

(Automatic close is disabled) (Automatic close is disabled)

Automatic close time 4s Automatic close time 14s

Instructions for GK SERIES

www.gatexpertstore.com

16

Common Faults and Countermeasures

No

.

Trouble

Possible Cause

Countermeasures

1

The STOP indicator

light on the control

box is off or LED1

indicator light of

circuit board is off.

1.The power supply is

not connected or the

wire connector is

loose.

Tighten the screw of the

wiring and re-power on.

2.The emergency stop

terminal is loose or

emergency stop button

is not reset.

Reinsert the emergency

stop terminal or reset the

emergency stop button.

3.Power has input,

while transformer

without voltage output.

Transformer has

damaged in transit.

Replace the circuit board.

4.The fuse in the single

phase control box is

burnt.

Replace the fuse.

2

After three phase

control panel is

powered on, LED2

indicator light on

circuit board keeps

flashing.

1.Phase sequence of

power connection is

wrong; phase

sequence detection is

activated.

Turn off the power,

exchange any two

phases among L1, L2,

and L3 until the LED2

indicator light is off.

2.Power phase

shortage.

Use a multimeter to find

out which power supply

phase is missing and

then rewiring.

3

CLOSE indicator light

keeps flashing, press

the buttons on control

box or remote control

buttons, the machine

cannot work.

1.The protective

device is activated, the

hand-pulled chain

mechanism is not

reset, the

disengagement

wrench is not closed.

pull green handle B to th

e bottom to close the

disengagement wrench.

Wait for a period of time

after the motor cools

down.

2. Limit faults.

1.Check whether the

terminals of machine and

control box are correctly

connected in accordance

with the instruction of

color or cable maker.

2.Whether the white limit

common wire inside the

control box is in poor

contact;

3.Whether the OPEN limit

cam and CLOSE limit

cam hold down the limit

switch simultaneously.

This manual suits for next models

6

Table of contents

Other GATEXPERT Gate Opener manuals

GATEXPERT

GATEXPERT PY300DCL User manual

GATEXPERT

GATEXPERT GT1000DC User manual

GATEXPERT

GATEXPERT SW400DC User manual

GATEXPERT

GATEXPERT PY300DC User manual

GATEXPERT

GATEXPERT INDUS-E Series User manual

GATEXPERT

GATEXPERT GT1000DCL User manual

GATEXPERT

GATEXPERT DKC500ACL User manual

GATEXPERT

GATEXPERT SW200DC User manual

GATEXPERT

GATEXPERT GA500DC User manual

GATEXPERT

GATEXPERT GT800ACL User manual