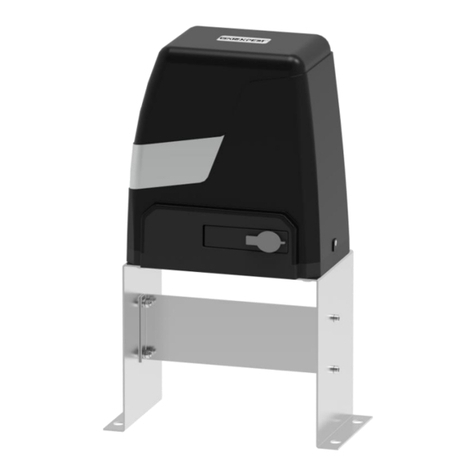

GA600AC Sliding Gate Opener User Manual

CONTENTS

Default Setting Instruction..............................................................................................................1

Parts List...........................................................................................................................................2

Technical Parameters.....................................................................................................................4

Installation........................................................................................................................................4

Before You Start..........................................................................................................................4

Tools Required / Example Sliding Gate......................................................................................4

Step 1 - Gate Preparation...........................................................................................................5

Step 2 - Checking Manual Release.............................................................................................6

Step 3 - Removing / Installing Motor Cover.................................................................................6

Step 4 - Motor Pad Footing.........................................................................................................7

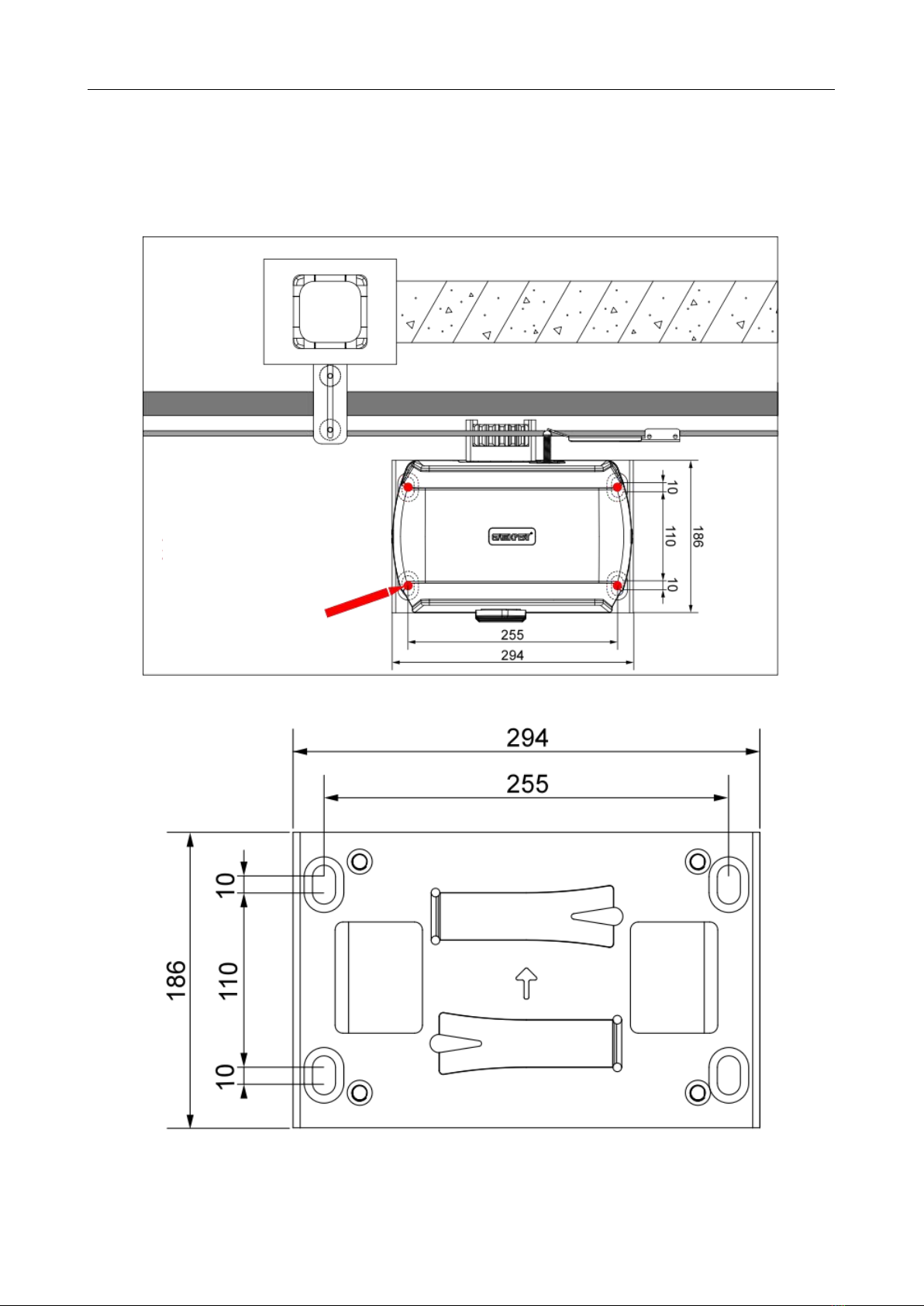

Step 5 - Fitting Mounting Plate and Motor...................................................................................8

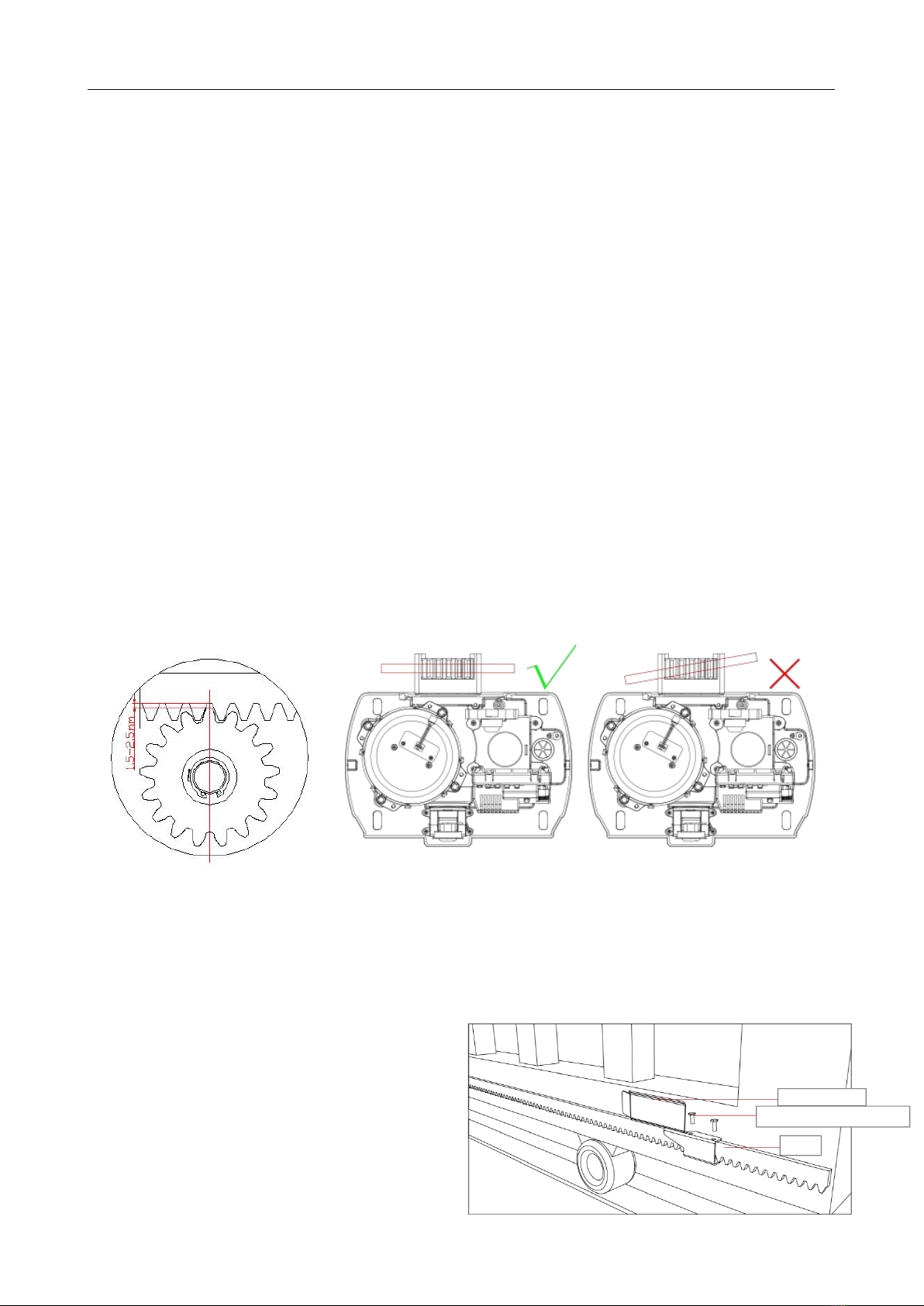

Step 6 - Motor Position Adjustment.............................................................................................9

Step 7 - Gear Rack & Motor Alignment.......................................................................................9

Step 8 - Limit Switch Stops.......................................................................................................10

Step 9 - Powering on.................................................................................................................13

Step 10 - Testing Travel and Limit Stops...................................................................................14

Control Board.................................................................................................................................15

Programming and Wiring..........................................................................................................15

DIP Switch Adjustment..............................................................................................................16

Potentiometer Adjustment.........................................................................................................17

Terminal Instructions.................................................................................................................18

Wiring to the Terminal................................................................................................................19

Connecting Infrared Photocells.................................................................................................20

Remote Control Learning and Clearing.....................................................................................21

Maintenance...................................................................................................................................26

Troubleshooting.............................................................................................................................26