GATEXPERT PY300DC User manual

Sliding Gate Opener

User Manual

PY300DC

Website: www.gatexpertstore.com

E-mail: sales@gatexpertstore.com

Instructions for PY300DC

www.gatexpertstore.com

WARNING

Instructions must be read before installation. Please follow these instructions carefully,

incorrect installation could affect gate operation.

When mounting and positioning this product please ensure the power cable is

unplugged.

The motor cover will need to be removed to mount the motor to the mounting plate or

directly to the concrete footing.

Any changes to the settings on this product can only be made by a licensed electrician.

This product can be powered by AC110V/220V power supply or backup battery power

and solar power.

Instructions for PY300DC

www.gatexpertstore.com

WARRANTY

1. To repair against this warranty card and invoice during the warranty period.

2. Warranty period: 1 year after the date of invoice.

3. Without unauthorized dismantling, any product broken or damage due to quality problem,

we’ll offer the repair service for free or replace for free.

4. The malfunction and damages caused by incorrect use or man fault is not covered by this

warranty.

CONTACT US

E-mail: sales@gatexpertstore.com

Please fill in the order information in the form below.

All personal information you provided will be only used for warranty service and kept

strictly confidential.

Refer to this list when contacting GATEXPERT for technical service or assistance with

your automatic gate opener.

Order Number

Product Model

Purchase Date

Country / Region

Email Address

Issue Details

Instructions for PY300DC

www.gatexpertstore.com

CONTENTS

Default Setting Instruction..............................................................................................................1

Safety Instruction.............................................................................................................................2

Parts List...........................................................................................................................................3

Technical Parameters......................................................................................................................4

Installation........................................................................................................................................4

Before You Start..........................................................................................................................5

Tools Required / Example Sliding Gate………............................................................................5

Step 1 - Gate Preparation............................................................................................................5

Step 2 - Checking Manual Release.............................................................................................6

Step 3 - Removing / Installing Motor Cover.................................................................................6

Step 4 – Motor Pad Footing.........................................................................................................7

Step 5 - Fitting Mounting Plate and Motor....................................................................................7

Step 6 - Gear Rack & Motor Alignment........................................................................................9

Step 7 - Powering on........................……..................................................................................11

Step 8 - Testing Travel and Limit Stops.....................................................................................11

Programming and Wiring..............................................................................................................12

Terminal Instructions.................................................................................................................13

Wiring to the Terminal...............................................................................................................14

Wiring to the Transformer..........................................................................................................14

Connecting Infrared Photocells.................................................................................................16

Remote Control Operation........................................................................................................18

Connecting Storage Battery......................................................................................................19

Connecting Solar Panel.............................................................................................................20

Maintenance...................................................................................................................................20

Troubleshooting.............................................................................................................................21

Drawing and Measurements..........................................................................................................22

Instructions for PY300DC

www.gatexpertstore.com

1

Then the gate will move

in the set direction.

Default Setting Instruction

The gate opener will open the gate to the right-hand side as its default setting. By default, the

opener mounts on the right-hand side. (Figure 1)

Gate in closed position Gate in open position

Figure 1

Before installation: Test the gate opener by plugging it into a power source and pressing the

remote. Press the opening button, the output gear rotates, then press the stop button, the output

gear stops rotating. Finally, press the closing button, the output gear rotates to the opposite

direction. This will give you an understanding of the way in which the opener will move the gate.

Figure 2

Note: Ensure that the gate opener is unplugged before proceeding with installation. Please keep

fingers away from the motor output gear whilst it is turning.

If your gate needs to open from the other direction (to the left, refer to figure 3), your opener needs

to be mounted on the left-hand side as shown, the relative wires need to be swapped over, please

check under “Terminal Instructions” for swapping. (Factory default setting is for right-hand opening:

opener mounted on the right-hand side).

Figure 3

Any works done to the gate opener must be completed whilst the power is off, and the opener is

unplugged.

Press the first/top

button on the remote.

Rotating output gear will

drive the gate frame.

Instructions for PY300DC

www.gatexpertstore.com

2

Safety Instruction

Warning: Incorrect or improper use of this product can cause damage to persons, animals or

properties.

·Please ensure that the input voltage used matches with the supply voltage of gate opener.

·All modifications to wiring or electrics, and any adjustment or maintenance to input voltage

must be done by a qualified electrician.

·All potential hazards and exposed pinch points of the gate must be eliminated or guarded prior

to installation of this gate opener.

·Never mount any device that operates the gate opener where the user can reach over (under,

around or through) the gate to operate the controls. These must be placed away from any

moving range of the moving gate.

·Ensure power plug is disconnected from the power socket during installation or maintenance.

·Keep remote control and other control devices out of children’s reach, in order to avoid

unintentional activation.

·To ensure safety, before installing the motor, mount a Gate End Catch and a Gate Stop at each

end of the rail to prevent the gate travelling off the track.

·If required, install infrared photocell to detect obstructions and prevent injury to person or

damage to property.

·Instruct all users about the control systems provided and the manual opening operation in case

of emergency.

·Ensure that the power cable is connected to a RCD protected weatherproof power outlet

installed by a qualified electrician.

·Do not install this product in an explosive atmosphere or where there is any danger of flooding.

·This product was exclusively designed and manufactured for the use specified in the present

documentation. Any other use not specified in this documentation could damage the product

and be dangerous.

·Only use original parts for any maintenance or repair operation. Our company declines all

responsibility with respect to the automation safety and correct operation when other supplier’s

components are used.

·Do not modify the automation components, unless explicitly authorized by our company.

·The user must avoid any attempt to carry out any works or repairs on this product, and should

always request the assistance of qualified personnel.

·This product is suitable for use on one sliding gate only.

·Anything which is not expressly provided for in these instructions is not allowed and will void

warranty.

·Dispose of all packing materials (plastic, cardboard, polystyrene etc.) according to current

guidelines. Keep plastic bags and polystyrene out of children’s reach.

·Save these instructions for future use.

Instructions for PY300DC

www.gatexpertstore.com

3

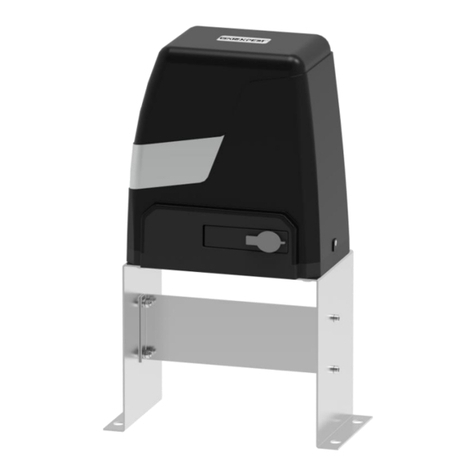

Parts List

Parts List (standard configuration)

No.

Picture

Name

Quantity

1

Motor

1

2

Manual Release Keys

2

3

Remote Controls

2

4

Accessories Box

1

5

Manual Release Bar

1

6

Anchor Bolts M8

4

6-1

Nuts M8

8

6-2

Flat Washers φ8

8

6-3

Spring Washers φ8

8

Note: Extra flat washers and spring washers are spare parts.

Parts List (optional)

No.

Picture

Name

Quantity

1

Galvanized Gear Rack

1m/pc

2

Nylon Gear Rack

1m/pc

3

Infrared Photocell

1

Instructions for PY300DC

www.gatexpertstore.com

4

No.

Picture

Name

Quantity

4

Wireless Keypad

1

5

Alarm Lamp

1

6

Mounting Plate

1

7

Hexagon Head Bolt

M8X40

4

Additional remote controls: Spare/Additional remotes for the automatic gate kit, these will need to

be paired to the motor.

Infrared photocell: Detects pedestrians, vehicles and objects that cross an infrared beam and

prevents the gate from closing.

Wireless keypad: Allows secure access through the gate used with a user set code.

Wired control: Allow users to control the opening and closing of the door through an external

push-button.

Alarm lamp: Alerts people near the gate and users that the gate is in operation.

Technical Parameters

Model

PY300DC

Power Supply

110VAC/60Hz; 220VAC/50Hz

Motor Power

100W

Gate Moving Speed

13m/min

Maximum Loading Weight

300KG

Remote Control Distance

≥30m

Remote Control Mode

Single button mode

Limit Switch

Electronic limit switch

Working Noise

≤60dB

Working Duty

S2, 20min

Recording of up Remote Controls

20

Remote Frequency

433.92 MHz

Working Temperature

-20°C - +70°C

Battery Specification

12V 4.5Ah*2pcs

Package Weight

11.32KG

Installation

Before You Start

·PY300DC Sliding Gate Automation Kit is suitable for powering the opening and closing motion

of gates up to 300kg in weight, up to a length of 8m.

Instructions for PY300DC

www.gatexpertstore.com

5

·Gate motion is achieved by the rotating output gear of the gate opener driving the gear rack

(sold separately) fitted to the moving gate.

·The gate opener requires you to press the remote control once to open, and once again to

close. This is a safety feature to ensure safe operation.

·The opener must be fitted within private property, never externally to a property’s boundary.

Any works done to the gate opener must be completed whilst the power is off and the opener is

unplugged. Any modifications/alterations/works to AC power components must only be completed by

a licensed electrician.

Tools Required

·Tape measure

·Level

·12mm concrete drill and hammer (when uses expansion screws)

·Phillips head screwdriver

·Straight screwdriver

Example Sliding Gate

Gate Track and Track Wheels Gate End Catch Gate Guide Rollers Gate Stop

Figure 4

Please ensure that the gate opener power cable is not plugged in at any stage before Step 7.

Step 1 - Gate Preparation

·Ensure that the sliding gate is correctly installed.

·The gate is horizontal and level and the gate can glide back and forth smoothly when moved by

hand before installing the gate opener.

·Wheels and guide rollers should rotate easily and be free from dirt or grime.

·Track should be flat, level and firmly affixed.

·Any misalignment in the gate will affect performance of the automatic gate opener.

Instructions for PY300DC

www.gatexpertstore.com

6

The gate should slide smoothly by hand before attempting to install the gate opener.

Figure 5

Step 2 - Checking Manual Release

·Insert the key and remove the motor case, open the manual release bar to enable the motor

get into manual mode and check that the motor output gear rotates freely by hand (Figure 6).

Figure 6

Step 3 - Removing / Installing Motor Cover

·Unscrew the two cover screws located at each side of the motor cover.

Figure 7

To make the motor into manual mode, insert the key

and remove the motor case, open the manual release

bar as shown.

In manual mode, the gear

can turn freely and the gate

can be operated by hand.

open the manual

release bar

Instructions for PY300DC

www.gatexpertstore.com

7

Step 4 - Motor Pad Footing

·The motor pad concrete footing requires an area of no less than 450mm long x 300mm wide

and a minimum depth of 200mm (Standard requirement).

·Ensure surface is level and parallel to the driveway.

Mounting Plate Dimensions

Figure 8

Step 5 - Fitting Mounting Plate and Motor

Without Mounting Plate

·Pre-embed the anchor bolts according to holes in motor base before concerting (as per Figure

9).

·Afater concrete hardening, bolt the motor with M8x40mm bolts, spring and flat washers provided

and tighten as required. (The height can be slightly adjusted by bottom bolts as per Figure 10).

Figure 9

Instructions for PY300DC

www.gatexpertstore.com

8

The bolts and flat washer between mounting plate and motor base are

used for adjusting the height of the motor.

The bolts and flat washer between mounting plate and motor base are

used for adjusting the height of the motor.

Figure 10

With Mounting Plate

·Pre-embed the anchor bolts as per Φ10 holes in Figure 8 before concreting, after hardening,

place the mounting plate, fit and tighten anchor bolts.(as per figure 11).

·Bolt motor to the mounting plate using the M8 x 40mm bolts with spring and flat washers

provided and tighten as required (as per figure 12).

Figure 11

Figure 12

Nut

Flat Washer

Flat Washer

Spring Washer

Nut

Nut

Flat Washer

Flat Washer

Spring Washer

Nut

Instructions for PY300DC

www.gatexpertstore.com

9

Fitting Motor

·Fit motor and mounting plate(if with) on the concrete footing.

·Ensure the motor output gear and gear rack are correctly aligned. Gear and gear rack should

be centered as much as possible.

·Take the motor away from mounting plate.

Figure 13

Step 6 - Gear Rack & Motor Alignment

·See Figure 15 for recommended gear rack mounting height.

·Ensure that the output gear has a minimum clearance of 1-2mm along the entire length of gear

rack fitted to the gate (as per Figure 14)

·Ensure output gear and gear rack are correctly aligned. Under no circumstances should the

gate opener output gear carry any weight of the gate. It is the task of the gate castors or wheels

to carry the weight of the gate (as per Figure 14).

·If the gate doesn’t slide freely by hand, adjust the height of the gear rack accordingly until the

full length of gate slides freely by hand.

Sliding Gate Frame (in open position)

Use pencil, chalk or similar

tools to mark at the corners of

mounting plate

Instructions for PY300DC

www.gatexpertstore.com

10

Figure 14

Figure 15

Open Position

Output Gear

Mounting Plate

Instructions for PY300DC

www.gatexpertstore.com

11

Step 7 - Powering on

·Ensure that the outer cover has been fitted and fastened back onto the motor base.

·Before powering up the gate opener make sure the gate can travel by hand in manual mode

(key unlocked).

·Slide the gate to between the middle of the posts, approximately (see below diagrams).

·Lock the manual release spanner (key locked) in readiness for automatic mode.

·Plug the power cord into an approved RCD protected weatherproof outlet.

·Remote controls included in this kit are factory paired ready for use.

Figure 16

Step 8 - Testing Travel and Limit Stops

·Ensure gate opener is installed as per step 5, 6 and the sliding gate is in the middle position.

·Please refer to control board setting(page 15) to set the open limit stop position and closed limit

stop position. The ideal closed final position for the gate frame is 10-15mm from closed gate

end catch.

·After setting up the limit stop positions, the sliding gate will automatically run to open limit stop

positon and then to the closed limit stop postion, do not cut off the power supply or stop the

gate during it’s Auto-running.

·Press remote (remotes included in kit are factory paired to the motor) or exteral push button,

the sliding gate will begin to move. When it arriaves at the limit stop position the sliding gate will

stop.

Now the basic open and closed positions are set, for further setting functions and adjusting

parameters, please refer to pages 12-20 in this manual.

Open Limit Stop Position

Closed Limit Stop Position

Instructions for PY300DC

www.gatexpertstore.com

12

J2 Terminal

J3 Terminal

J4 Terminal

Transformer

Secondary

(AC24V/3.3A)

Programming and Wiring

Any works to the 110V/220V AC must only be performed by a licensed electrician.

Ensure power is off before any modifications are made.

Figure 17

DC Motor

Solar Panel and

Storage Battery

Hall Sensor

Instructions for PY300DC

www.gatexpertstore.com

13

Terminal Instructions

All changes to these settings below must be completed by licensed electrician.

Terminal DC Motor: Black connect to “T1”, red connect to “T2”, if the running

direction is opposite, please exchange “T1” and “T2”.

J4 Terminal:

Terminal LAMP+: Alarm Lamp +24VDC

Terminal LAMP-: Alarm Lamp -24VDC

J3 Terminal:

Terminal GND: Common Terminal for Photocell

Terminal PE: Photocell Input (N.C.).

Terminal +24: Additional Accessories +24VDC

Additional accessories sold separately.

J2 Terminal:

Terminal OSC: Single Cycle for External Push Button

(open/stop/close)

Terminal COM: Common Terminal for External Push Button.

Terminal OPEN: External Open Push Button Switch.

Terminal STOP: External Stop Push Button Switch.

Terminal CLOSE: External Close Push Button Switch.

Instructions for PY300DC

www.gatexpertstore.com

14

Insert the wire into the

number on the terminal that

you are looking to connect to.

Refer to Page 12.

Tighten with a screwdriver

to secure the wire in place.

Wiring to the Terminal

Wiring to the Transformer

Figure 18

Using a screwdriver to

loosen the screw on the

side of the terminal.

Transformer Input 220VAC

Transformer

output 24VAC

T2

T1

Instructions for PY300DC

www.gatexpertstore.com

15

Setting the Open and Closed Position

1. Press and hold SET until digital dispalys “1”.

2. Press and hold OPEN until gate opens to a proper open position(The open position will

be determined by customer themselves. Note: Press OPEN, the gate will open, if it’s not

opening, please change the motor wire “T1” and “T2”)

3. Press SET to confirm the open position, the digital will dispaly “2”.

4. Press and hold CLOSE until gate closes to a proper closed position.(The closed position

will be determined by customer themselves.)

5. Press SET to confirm the closed position.

6. After these steps, the gate will automatically run a complete opening and closing cycle.

Figure 19

Adjusting the Auto-close Time:

1. Press and hold OPEN until digital display “—”.

2. Press OPEN to add the time for Auto-close, press CLOSE to reduce the time.

3. If the time setting is 0, there will be no Auto-close function.

4. Press SET to confirm.

5. The number increase by 1, the time will add by 10 seconds.

Note: The Auto-close function will work only after the sliding gate runs to open

position.

Instructions for PY300DC

www.gatexpertstore.com

16

Figure 20

Setting the Reverse Function After Meeting Obstacles

If the sliding gate meets an obstacle during closing, it will stop and reverse 15-20cm.

1. Press and hold SET until digital dispalys “3”.

2. Press OPEN to increase the sensitivity of meeting obstacles, the strogest level is 9,

press CLOSE to decrease the sensitivity, 1 is the lowest level.

3. Press SET to confirm the setting.

Note: The sensivity should be set according to the gate weight to ensure the reverse

function is workable, or it may have potential safety concerns.

Figure 21

Connecting Infrared Photocells

Highly recommend the use of infrared photocells as an additional safety feature.

1. Press and hold CLOSE until digital dispalys “—”.

2. Press OPEN, digital disaplays “H”, the photocell funtion is enabled.

3. Press CLOSE, digital disaplays “||”, the photocell funtion is disabled.

4. Press SET to confirm your setting. (If there is no photocell connected, please set it as

“||”)

Table of contents

Other GATEXPERT Gate Opener manuals

GATEXPERT

GATEXPERT PY300DCL User manual

GATEXPERT

GATEXPERT PY1200AC User manual

GATEXPERT

GATEXPERT GT1000DCL User manual

GATEXPERT

GATEXPERT SW400DC User manual

GATEXPERT

GATEXPERT GT800ACL User manual

GATEXPERT

GATEXPERT GA600AC User manual

GATEXPERT

GATEXPERT GT1000DC User manual

GATEXPERT

GATEXPERT GK Series User manual

GATEXPERT

GATEXPERT SL500DCL User manual

GATEXPERT

GATEXPERT DKC500DCL User manual