GATmatic TWC-1600 User manual

TIRE CHANGER FOR TRUCK TWC-1600

AUTOMATIC TIRE CHANGER

INSTRUCTION MANULA

TIRE CHANGER

ITEM NO: TWC-1600

TIRE CHANGER FOR TRUCK TWC-1600

1

1 GENERAL INFORMATION

Tire changer has been specifically designed to demount high-speed bus and

truck tires with rims form 14"to 26"and a maximum 1600mm diameter

Any other use is improper and therefore not authorized before beginning any

kind of work on or with this machine, carefully read and understand the

contents of these operating instructions.

Shall not liable for any injury to persons or damage to things caused by

improper use of this machine.

Keep this manual near the machine and consult it as needed during

operations.

2 TECHNICAL DATA

Pump motor

1.5KW

Gear-box motor

1.8KW

Handles rim form

14"-26"

Max. wheel diameter

1.600mm

Max. wheel width

780mm

Weight(with standard accessories)

518kg

Acoustic pressure level(at work)

LPA<70dB(A)

3 GENERAL SAFETY REGULATION

The use of this machine is reserved to specially trained and authorized

personnel.

Any unauthorized changes or modifications to the machine, in particular to its

electrics system, relieve form all liability.

Removing or tampering with the safety devices installed on this machine is in

violation of European safety Regulations.

4 SAFETY DEVICES

Tire changer has a number of safety devices designed to guarantee the utmost

operator safety:

1. Check valve on the spindle opening hydraulic line (inside the swivel

connector, see fig. B/1).This prevents the wheel form falling form the spindle

if the hydraulic is accidentally broken.

2. pilot operated dual seal check valve(see Fig. B/2)

This prevents the spindle carrier arm from dropping if the hydraulic circuit

accidentally breaks.

3. Pressure relief valve factory set at 130 bar ±5%(see Fig. B/3).

Any work, however minor, on the electric system must

be done exclusively by professionally qualified

personnel.

TIRE CHANGER FOR TRUCK TWC-1600

2

This limits the pressure in the hydraulic circuit and ensure correct operation

of the plant.

4. Pump motor overload cut-out (inside the electric enclosure).

This cuts in if the motor overheats to prevent it from burning out.

5. Mechanical tool arm tip lock device (see Fig. B/4).

Prevents the arm form being moved to its “non-working position” if the tool

has been removed.

CAUTION!

Removing or tampering with safeties is in violation of European Safety

Regulations and relieves manufacturer of any and all liability for injury to

persons to damage to things caused or referable to such acts.

5 TRANSPORT

Depending on customer request, the machine is delivered in 3 packing

versions:

1-in a wooden crate with pallet

2-fixed to a pallet

3-no packing

In all cases the machine is protected by a plastic covering.

In the first and second case, the machine must be handled with a fork-lift truck

with the forks positioned as shown in the figure.

TIRE CHANGER FOR TRUCK TWC-1600

3

6 UNPACKING

Once the packing material has been removed, check the machine visually for

any signs of damage.

Keep the packing materials out of the reach of children as they can be a source

of danger.

N.B.: Keep the packing for possible future transport.

7 INSTALLATION PLACE

Choose the place the machine is to be installed in compliance with current work

place safety regulations.

The floor should not be broken or uneven so that the machine will be stable and

the platform rollers can move freely.

If the installation is outdoor, it must be protected by some kind of roofing

against rain.

The following work environment conditions are applicable: Relative

humidity :form 30-95% without condensation; Temperature: form 0-55℃.

WORKPLACE REQUIREMENTS

Maximum machine space requirements are 1950×1600mm with a minimum

distance from walls as shown in the diagram.

Caution! These measurements are also the tire changers working range.

Persons other than specially trained and authorized operators are

expressly forbidden to enter this area.

Position the tire changer lifting it with the specific bracket (1, fig. A) with the tool

carrier arm (2, Fig. A) lowered all the way. The spindle (3, Fig. A) closed and

the tool carrier slide (4, Fig. A) at its stop close to the arm.

ATTENTION!

The machine must not be operated in explosive atmospheres.

TIRE CHANGER FOR TRUCK TWC-1600

4

It is not essential to anchor the machine to the floor however, the floor must be

smooth and permit the platform rollers to move freely.

ELECTRIC HOOK UP

Before making any electric hook up, check to be certain that the mains

voltage corresponds to that stamped on the voltage tag (attached to the

cord near the tire changer’s plug).

It is absolutely essential that:

-the system is equipped with a good grounding circuit.

-The machine is connected to a power supply line circuit breaker set for

30 mA.

-The current in-stake is adequately protected against over-currents with

fuses or automatic magneto-thermic switch with rated values as shown in

the table.

Note the required power draw as high-lighted on the data plate fixed to

the tire changer. Check to make sure the shop electric wiring circuit is

dimensioned sufficiently to carry this.

Manufacturer shall not be liable for any injury to persons or damage to

things caused by failure to comply with these regulations and can cancel

warranty coverage.

SENSE OF ROTATION CHECKS

power supply

Rated current

Fuse

Switch

220v-3ph-50/60Hz.

10A

16A

Work on the electric system, even if minor, must be done

exclusively by professionally qualified personnel.

TIRE CHANGER FOR TRUCK TWC-1600

5

Connect the machine to the mains, switch “ON”(5,fig.B/7)and check that the

gearbox motor rotation corresponds to the indicating arrow(6,fig.B/6).

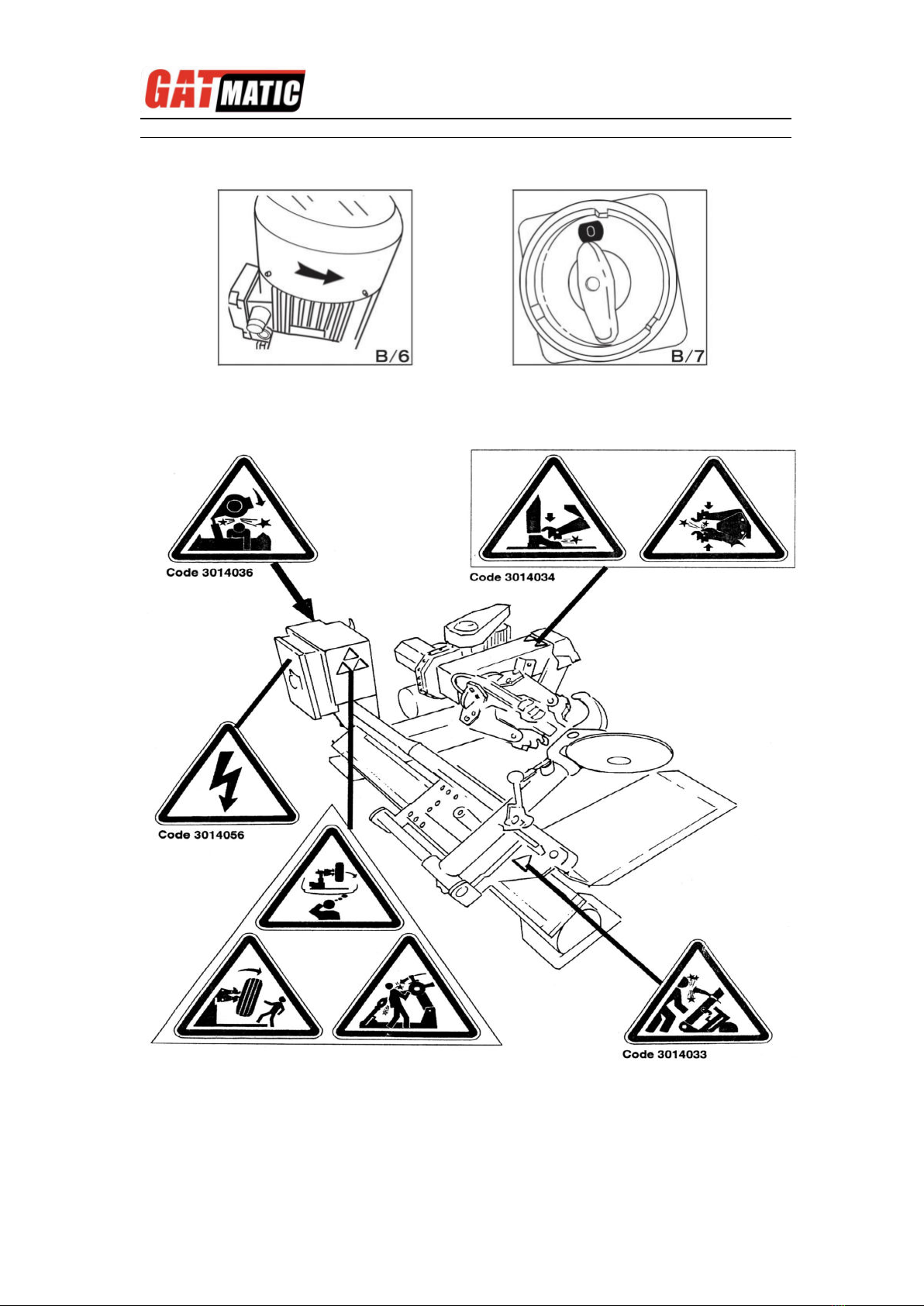

8 IDENTIFYING WARNING SIGNALS

WARNING!

Unreadable and missing warning labels must be

replaced immediately.

Don’t interpose any object witch could prevent the

operator from seeing the labels.

Use the code in this table to order labels that you

might need.

TIRE CHANGER FOR TRUCK TWC-1600

6

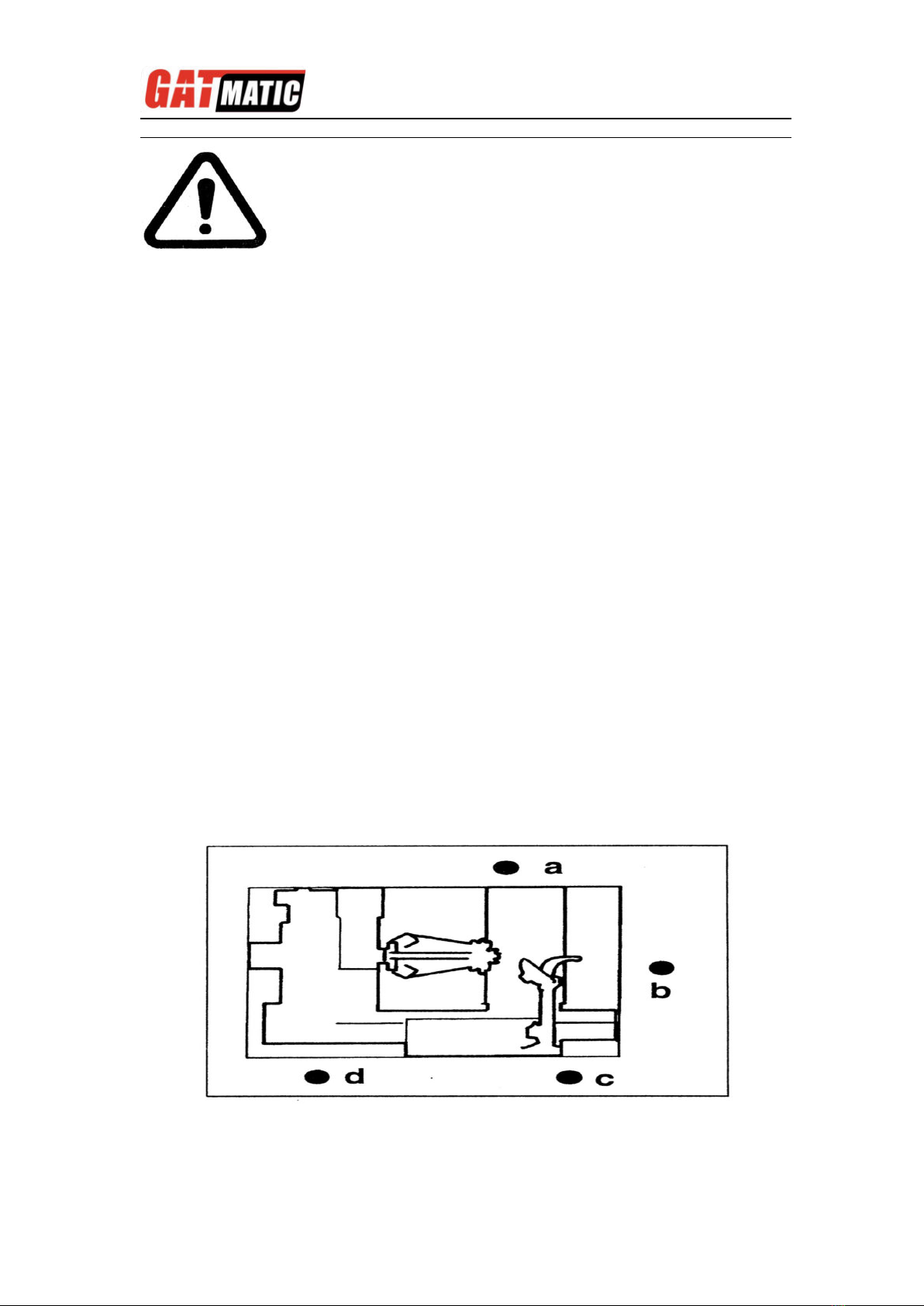

9 IDENTIFICATION OF CONTROL

The mobile control center (fig. c) enables the operator to work at any position

around the machine .on this mobile control center the following controls are

located:

-The lever (8, fig. c) which in position a lifts the chuck arm and in position b

lowers it; in position cmoves the tool holder arm and in position dmoves them

away. (Note: in order to memorize this operation, there is a hole in the lever

guard corresponding to position c).

-The chuck switch (9, fig. c) when moved upwards, opens the arms of the

self-centering chuck (LOCKING), and when moved down, close the arm of the

self-centering chuck (UN-LOCKING).

-The pedal (10, fig. c) when pressed on the left or right side rotates the

self-centering chuck in the same direction as shown by the arrows placed on

the foot pedal.

NOTE: all the controls are very sensitive and small movements of the .machine

can be done with precision.

The GATMATIC TWC-1600 tire changer also has:

Lever (15, Fig. D) to tip the tool carrier arm (14, Fig. 4) form its work to its

non-working position and vice-versa.

Handle (19, Fig. D) that permits alternative use of the bead-breaking disk

(17,Fig.D)or the hooked tool(18,Fig.D).

10 WORKING POSITION

The diagram shown here illustrates the various working positions

(A, B, C, D) referred to in the following pages describing how to use the tire

changer.

Use of these positions ensures greater precision, speed and safety for those

TIRE CHANGER FOR TRUCK TWC-1600

7

using the machine.

11 CORRECT OPERATION CHECKS

Before using the tire changer, a number of checks should be made to ensure it

works correctly.

CAUTION! The operations described here should be done with the tool carrier

arm in its non-working position.

First use lever (15, Fig. d) to tip the arm to this position.

1) Move the joystick (8, Fig. c) up (a): the spindle carrier arm (2, Fig. a) should

lift; move the joystick down (b): the arm should lower. Move the joystick

towards the left (C): the tool carriage and the mobile platform (13, Fig. D)

Should move towards the spindle (3, Fig. A);move the joystick towards the

right (d) the carriage and platform should move away from the spindle.

2) Tum switch lever (9, Fig. C) towards the top: the spindle arm should

open; move the lever down and the spindle arms should close.

3) Depress the right pedal (10, 568 Fig. C): the spindle (2, Fig. A) should turn

clockwise; depress the left pedal: the spindle should turn anticlockwise.

4) Check to be certain the hydraulic circuit is working correctly:

-move switch lever (9, Fig .c) towards the top until the spindle arms are fully

extended.

CAUTION!

Do not move your face close to the tool carrier arm when you

release it to tip it as needed.

DANGER!

When the spindle carrier arm is lowered. There is

always a potential for crushing anything in its

movement range. Always work from the position given

in the instructions keep well out of the working range

of the various moving arms.

(2, Fig. A)

DANGER!

When the spindle arms open or closed, there is always a

potential for crushing anything in their movement

range.

Always work form the position given in the instructions

keep well out of the spindle’s working range.

Lifting arm lift or lower and hydraulic chuck open or close, there is

always a potential for crushing anything in its movement range.

Always work form the position given in the instructions keep well

out of the working range

TIRE CHANGER FOR TRUCK TWC-1600

8

-hold the switch lever in this position (Top) and check if the pressure shown on

the gauge on the swivel fitting is 130 bar 5%.

If the pressure shown in not as indicated here, do not use the tire changer

and call our GATMATIC assistance team.

12 USE

LOCKING THE WHEEL

Always remember that the safest locking is on the central flange.

WARNING!

In locking the wheel, make sure that clamps are properly

positioned on the rim, so as to prevent the tire form falling

WARNING!

During all operations, keep hands and the other parts of the body as possible

form moving parts of the machine.

Necklaces, bracelets and too large clothes can be dangerous for the operator.

1) Take the mobile control unit to work position B.

2) Pull the tool-holder arm (14, Fig. D) into the upright

position.

3) Operating form the mobile control center, move the sliding table (13,

fig. D) away form the self-centering chuck and place the wheel in vertical

position on the sliding table.

4) Continuing to operate form the mobile control center, lift or lower the

arm in order center the self-centering chuck (3, fig. a) relative to the

rim.

5) With the jaws (22, fig. A) in the closed position, move the wheel on

the sliding table to the self-centering chuck. Operate the chuck switch

(9, fig. C) to open the self-centering chuck and lock onto the inside wheel

rim. The most convenient locking position on the rim may be selected

according to figE/1-E/2-E/3-E/4-E/5 and E/6.

TIRE CHANGER FOR TRUCK TWC-1600

9

N.B. for rims with channel, clamp the wheel so that the channel is near the

outside of the rim (fig. E/1)

TUBELESS AND SUPERSINGLE WHEELSBEAD

BREAKING

1) Look the wheel on the self-centering chuck, as previously described, and

ensure that the tire is deflated.

2) Take the mobile control unit to work position C.

3) LOWER THE TOOL-HOLDER ARM (14, Fig. F) into is working position and

allow it to lock.

4) Operating form the mobile center, manoeuvre the wheel until the outside of

the rim skims the bead-breaker disk (fig. F).

5) Rotate the wheel and at the same time, advance the bead-breaker plate

with small forward movements following the profile of the rim, with the plate.

6) Continue until the first bead is fully detached. To facilitate this operation,

lubricate the bead and the edge of rim with tire lubricant whilst the wheel is

rotated.

DANGER!

This operation can be extremely dangerous.

Do it manually only if you are certain you can keep the wheel

balanced.

For large and heavy tires an adequate lifting device must be used.

DANGER!

Do not very the area with a wheel clamped on the tyre changer

and lifted up from the floor.

TIRE CHANGER FOR TRUCK TWC-1600

10

Remember that the stronger the tire’s adherence to the rim. The slower must be

the disk’s penetration.

7) Bring the tool carrier arm (14, Fig. F) back form the edge of the rim. Release

the hook, raise the arm to its non-working position, shift it and rehook it in its

second work position (Fig. G).

8) Push the double headed tool lever (19, Fig. G) and turn the head 180º until it

locks automatically.

Then slide the tool-holder arm along the sliding table and lock it in position.

Repeat the operation previously described until the second bead is completely

broken.

DANGER!

Always check to be certain that the arm is corrected hooked to

the carriage.

DANGER!

The bead breaker disk must NOT be pressed against the rim but

against the bead.

CAUTION!

To avoid all risk, lubricate the beads turning the wheel

CLOCKWISE if you are working on the outside plane and

ANTICLOCKWISE if working on the inside plane.

DANGER!

Do not hold your hands on the tool when you bring it back

to its work position. Your hand(s) could be trapped between

the tool and the wheel.

9) Take the mobile control unit to work position D.

TIRE CHANGER FOR TRUCK TWC-1600

11

N.B.: During the bead breaking. The claw (18, Fig. G) can be lowed so that it is

out of the way.

DEMOUNTING

Tubeless tires can be demounted in two ways:

1) If the tire is not difficult to demount, once the beads have been loosened, use

the bead disk to push against the inside plane of the tire until both beads come

off the rim (see Fig. H)

2) With supersingle or very hard tires the procedure described above cannot be

used. The hook tool will have to be used as follows:

-Transfer the tool carrier arm to the outside plane of the tire.

-Rotate the wheel and at the same time move the hook tool forward inserting it

between rim and bead until it is anchored to the bead (see Fig. I)

-Move the rim 4-5 cm form the tool taking care that it does not unhook form the

bead.

-Move the hook tool towards the outside until the red reference dot is by the

outside edge of the rim.

-Insert lever BL (17, Fig. I) between rim and bead at the right of the tool.

-Press down on the lever and lower the wheel to bring the edge of the rim about

5 cm form the hooked tool.

-Turn the wheel anticlockwise pressing down on lever BL until the tool bead is

completely off.

-Move the tool carrier arm to its non-working position and then move it to the

inside plane of the wheel.

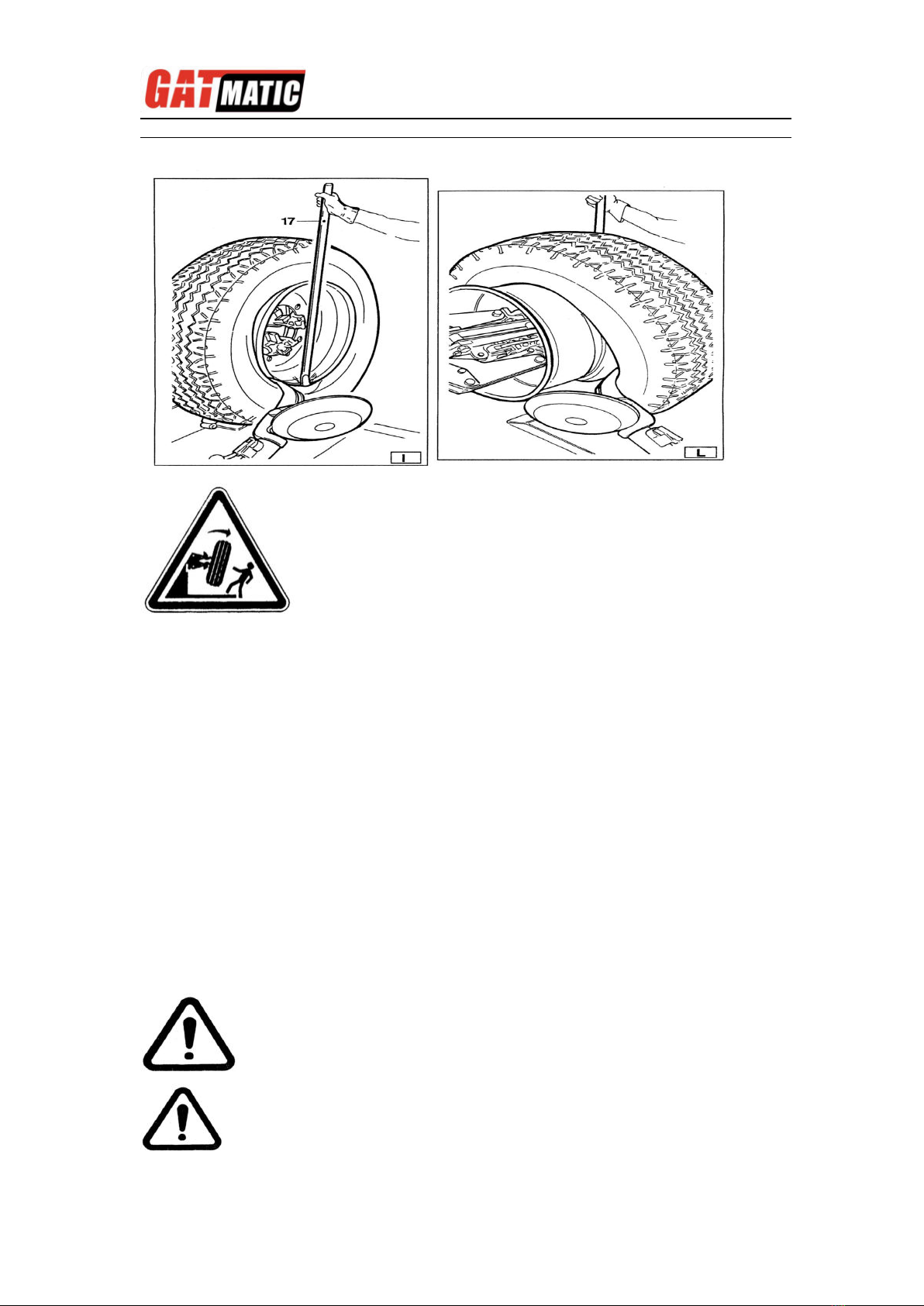

-Turn the hook tool 180º and insert it between rim and bead (see Fig. L). Move

it until the bead is by the edge of the rim (best to do this with the wheel turning).

-Move the rim about 4-5 cm from the tool making sure the hook does not detach

form the rim.

-Move the hook tool so that its red reference dot is about 3 cm inside the rim.

-Insert lever BL (17,Fig.I) between rim and bead at the right of the tool.

-Press down on the lever and lower the wheel to bring the edge of the rim about

5 cm form the hooked tool. Turn the wheel anticlockwise pressing down on

Take the mobile control unit to work position C.

Take the mobile control unit to work position B.

Take the mobile control unit to work position D.

Take the mobile control unit to work position B.

TIRE CHANGER FOR TRUCK TWC-1600

12

lever LA until the tire comes completely off the rim.

MOUNTING

Tubeless tires can be mounted using either the bead breaker disk or the hook

tool. If the tire is not problematic, use the bead loosener disk. If the tire is very

rigid, the hook tool must be used.

TIRE MOUNTING WITH THE DISK

Follow these steps:

1) If the rim has been removed form the spindle, put it back on the spindle as

described in the section on “CLAMPING THE WHEEL”

2) Lubricate both beads and the rim with tire manufacturer recommended

lubricant.

3) Attach the RP clip to the outside edge of the rim at the highest point (see

Fig.M).

4) Put the tire on the platform and lower the spindle (make sure the clip is at

the high point).

DANGER!

When the beads come off the rim, the tire will fall.

Check to make sure there are no bystanders in

the work area.

CAUTION!

Make sure the clip is firmly attached to the rim.

Take the mobile control unit to work position B.

TIRE CHANGER FOR TRUCK TWC-1600

13

5) Lift the rim with the tire hook to it and turn it anticlockwise about 15-20 cm.

The tire will be positioned tilted across the rim.

6) Position the bead loosener disk against the second bead of the tire and turn

the spindle until the clip is at the low point(at 6 o’clock)

7) Move the disk away form the wheel.

8) Remove the clip and replace it at 6 o’clock outside the second bead (see

Fig.N).

9) Turn the spindle clockwise 90º to bring the clip to 9 o’clock.

10)Move the disk forward until it is about 1-2 cm inside the edge of the rim.

Begin to turn the spindle clockwise checking to make sure that, with a 90º

turn, the second bead begins to slip into the center well.

11)When the bead is fully mounted, move the tool away form the wheel, tip it to

its non-working position and remove the clip.

12)Position the platform under the wheel, lower the spindle until the wheel rests

on the platform.

13)Close the arms of the spindle completely. Support the wheel to prevent it

falling off.

14)Move the platform to remove the wheel form the spindle.

15)Remove the wheel.

NB: If the tire permits it, the operation described above can be speeded

up by mounting both beads at the same time:

Take the mobile control unit to work position C.

Take the mobile control unit to work position B.

DANGER!

This operation can be extremely dangerous. Do it manually only

if you are certain you can keep the wheel balanced.

For large and heavy tire an adequate lifting device must be used.

TIRE CHANGER FOR TRUCK TWC-1600

14

-Follow the steps described under points 1,2,3,4 described above but instead

attaching the clip to just the first bead (refer to point 4)clip it to both.

-Lift the rim with the tire hooked to it and turn it anticlockwise 15-20 cm (clip at

10 o’clock).

-Follow the steps described in points 10,11,12,13,14,15 above.

MOUNTING WITH THE HOOKED TOOL

1) Follow the steps described in points 1,2,3,4,5 for mounting with the disk.

2) Move the tool carrier arm to its non-working position. Move it to the inside

plane of the tire and rehook it at this position.

3) Check to make sure the hook tool is positioned on the wheel side. If not,

press lever (19,Fig.D)and turn it 180º.

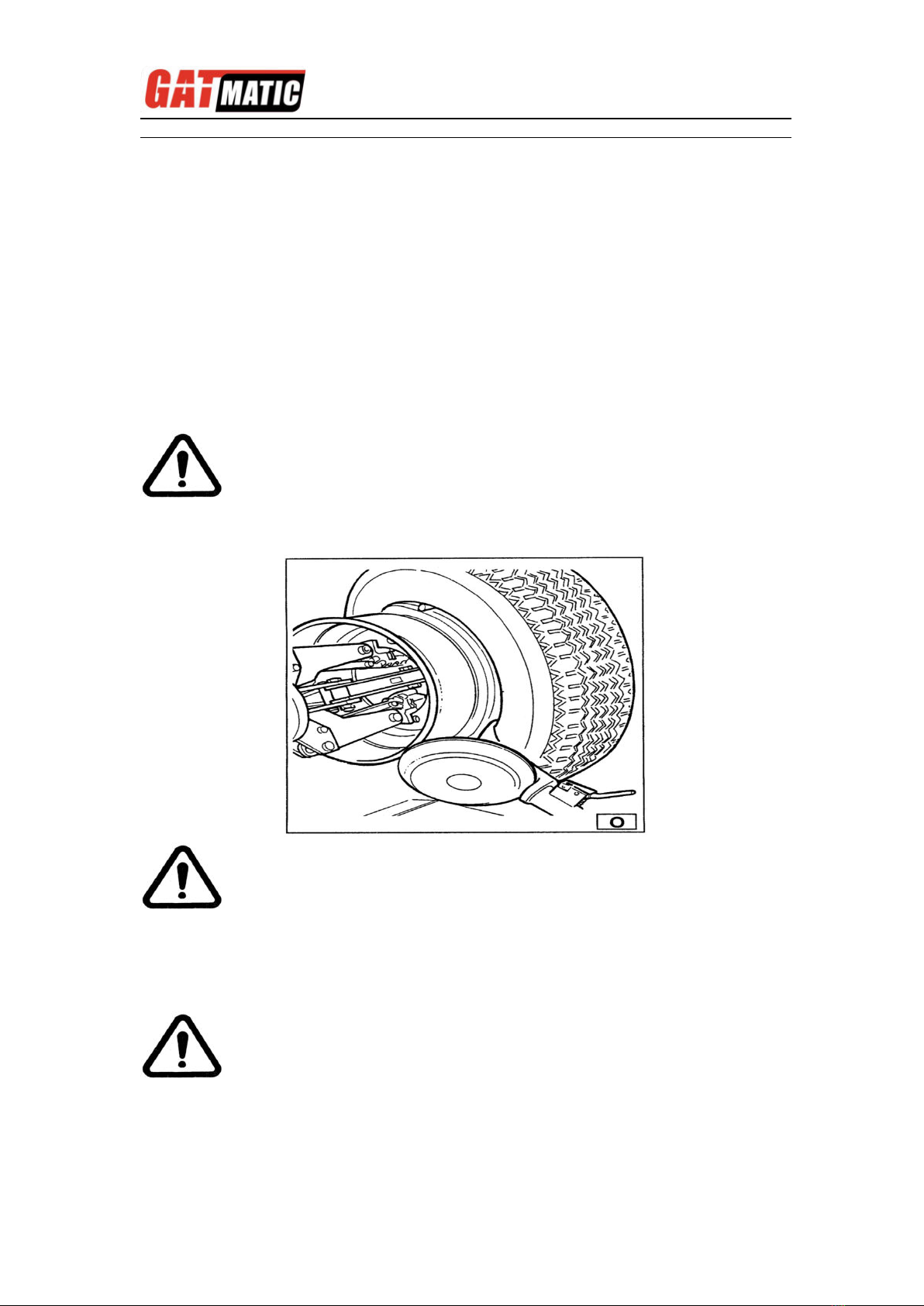

4) Move the tool forward until the red reference dot is lined up with the outside

edge of the rim and about 5 mm form it(see Fig.O).

5) Move to the outside of the wheel and check the exact position of the took

visually and adjust it as needed. Then turn the spindle clockwise until the

clip is at the bottom (6 o’clock). The first bead will be on the rim.

6) Remove the clip.

7) Remove the tool from the tire.

8) Move the tool carrier arm to its non-working position. Move it to the outside

plane of the tire and rehook it in this position.

9) Turn the tool 180º with lever (19,Fig.D).

Take the mobile control unit to work position D.

Take the mobile control unit to work position C.

Take the mobile control unit to work position D.

TIRE CHANGER FOR TRUCK TWC-1600

15

10) Attach the clip at the bottom (6,o’clock) outside the second bead(see

Fig.N)

11)Turn the spindle clockwise to about 90º (clip at 9 o’clock).

12)Bring the tool forward until the red reference dot is lined up with the outside

edge of the rim and about 5 mm form it. Begin to turn the spindle clockwise

and check if, after about 90º of rotation the second bead has started to slip

into the center well. Continue turning until the clip is at the bottom (6 o’clock).

The second bead will now be mounted on the rim.

13)Follow the steps described in points 11,12,13,14,15 for mounting with the

disk since this will ensure that the wheel is removed correctly form the

machine.

TUBED WHEELS BEAD BREAKING

WARNING: Unscrew the bush which fixes the valve when deflating the tire

so that the valve, coming in the inside of the rim, is not an obstacle during

bead breaking.

Follow all the steps described previously for bead breaking tubeless tires.

With tubed tires, however, stop disk movement as soon as the bead has

loosened to avoid damaging the tube inflation valve.

DEMOUNTING

1) Tip the tool carrier arm (14, Fig. D) to its non-working position. Move it to the

outside plane of the wheel and rehook it in this position.

2) Rotate the wheel and at the same time move the hook tool (18, Fig. D)

forward inserting it between rim and bead until it is anchored to the tool.

3) Move the rim 4-5 cm form the tool taking care that it does not unhook form

the bead.

4) Move the hook tool towards the outside until the red reference dot is by the

outside edge of the rim.

5) Insert lever BL (see Fig. P) between rim and bead at the right of the tool.

6) Press down on the lever and lower the wheel to bring the edge of the rim

about 5 cm from the hooked tool.

7) Turn the wheel anticlockwise pressing down on lever BL until the bead is

completely off.

Take the mobile control unit to work position C.

Take the mobile control unit to work position C.

Take the mobile control unit to work position B.

TIRE CHANGER FOR TRUCK TWC-1600

16

8) Move the tool carrier arm to its non-working position. Lower the spindle until

the tire is pressed down against the platform. As the platform is moved

slightly towards the outside, the tire will open a little and thus create enough

space to remove the inner tube.

9) Remove the inner tube and lift wheel back up.

10)Move the tool carrier arm to the inside plane of the tire, turn the hook tool

180º and lower the arm to its work position. Insert it between rim and bead

and move it until the bead is by the form edge of the rim ( best to do this with

the wheel turning).

11) Move the rim about 4-5 cm form the tool making sure the hook does not

detach from the rim.

12) Move the hook tool so that its red reference dot is about 3 cm inside the

rim.

13) Insert lever BL between rim and bead at the right of the tool (see Fig. Q).

14) Press down on the lever and lower the wheel to bring the edge of the rim

about 5 cm from the hooked tool. Turn the wheel anticlockwise pressing

down on lever BL until the tire comes completely off the rim.

MOUNING

1) If the rim has been removed from the spindle, put it back on the spindle as

described in the section on “CLAMPING THE WHEEL”.

2) Lubricate both beads and the rim with tire manufacturer recommended

lubricant.

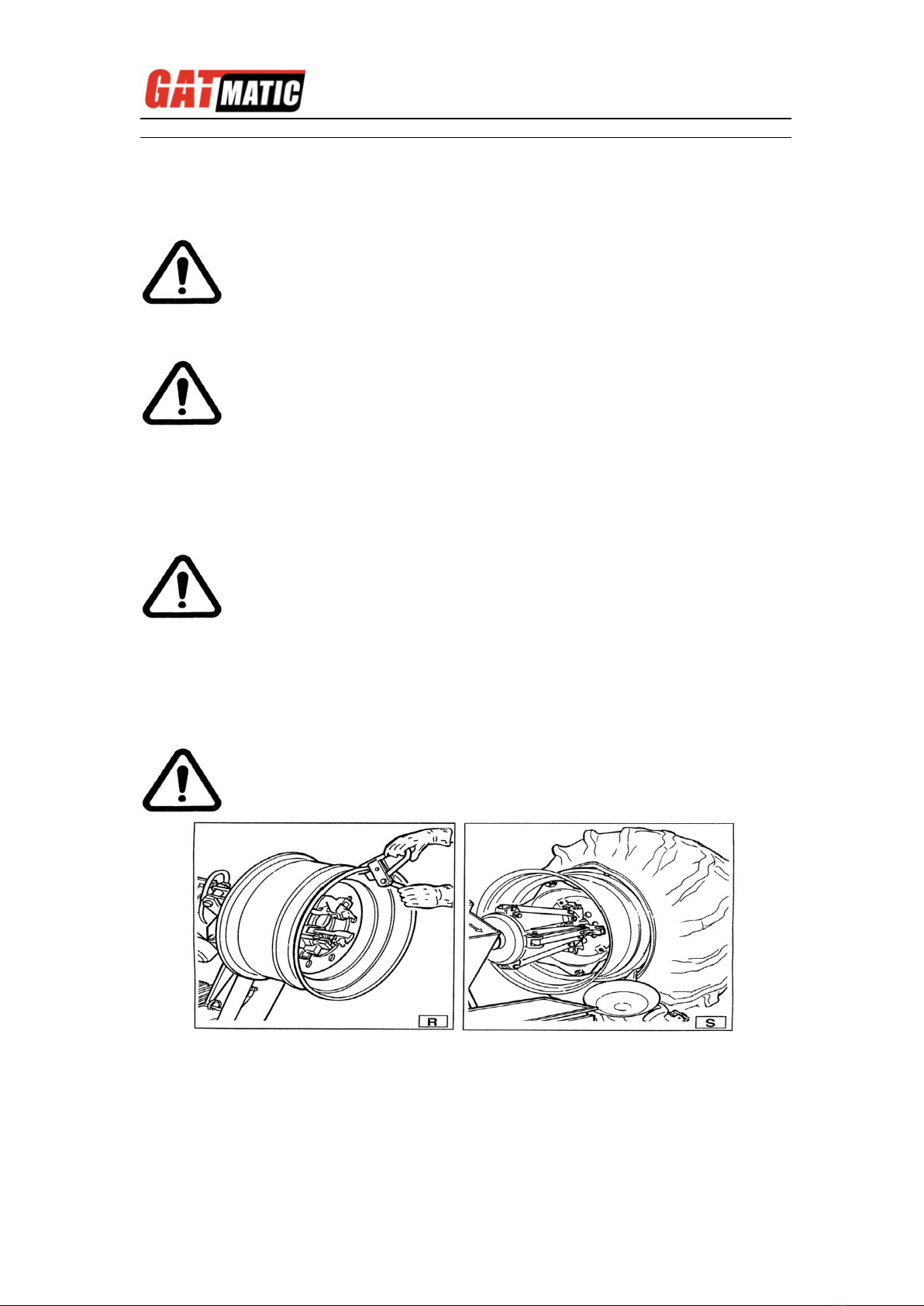

3) Attach the RP clip to the outside edge of the rim at the highest point (see Fig.

R).

4) Put the tire on the platform and lower the spindle (make sure the clip is at

the high point) to hook the first bead on the clip.

5) Lift the rim with the tire hook to it and turn it anticlockwise about 15-20 cm.

The tire will be positioned tilted across the rim.

Take the mobile control unit to work position D.

Take the mobile control unit to work position B.

DANGER!

When the beads come off the rim, the wheel will fall. Check to

make sure there are no by-standers in the work area.

CAUTION!

Make sure the clip is firmly attached to the rim.

Take the mobile control unit to work position B.

TIRE CHANGER FOR TRUCK TWC-1600

17

6) Move the tool carrier arm to its non-working position. Move it to the inside

plane of the tire and rehook it in this position.

7) Check to make sure the hook tool is positioned on the wheel side. If not,

press lever (19,Fig.D)and turn it 180º.

8) Move the tool forward until the red reference dot is lined up with the outside

edge of the rim and about 5 mm from it(see Fig.S)

9) Move to the outside of the wheel and check the exact position of the hook

visually and adjust it as needed. Then turn the spindle clockwise until the

clip is at the bottom (6 o’clock). The first bead will be on the rim. Remove the

clip.

10) Remove the tool from the tire.

11) Move the tool carrier arm to its non-working position. Move it to the outside

plane of the tire.

12) Turn the tool 180º with lever(19,Fig.D)

13)Turn the spindle until the valve hole is at the bottom (6 o’clock).

14)Move the platform (4 Fig. A) under the wheel and lower the spindle until the

tire is pressed down against the platform. As the platform is moved slightly

towards the outside, the tire will open a little and thus create enough space

to insert the inner tube.

NB: The valve hole may be asymmetrical to the center of the rim. In this

case position and insert the inner tube as shown in Fig .T.

Take the mobile control unit to work position D.

Take the mobile control unit to work position C.

Take the mobile control unit to work position D.

Take the mobile control unit to work position B.

TIRE CHANGER FOR TRUCK TWC-1600

18

Insert the valve through the hole and fix it with its locking ring.

15)Place the inner tube in the center well of the rim (NB: to facilitate this, turn

the spindle clockwise).

16)Turn the spindle until the valve is at the bottom (6 o’clock).

17)Inflate the inner tube a little (until it has no folds) so as not to pinch it while

mounting the second bead.

18)Attach an extension to the valve and then remove the locking ring.

NB: The purpose of this operation is to allow the valve to be loose so that

it is not ripped out during second bead mounting.

19)Move the tool carrier arm (14, Fig. D) to its working position.

20) Bring the tool forward until the red reference dot is lined up with the outside

edge of the rim and about 5 mm from it.

21)Pull back on this lever which will guide the bead into center well. Continue to

turn the spindle until the tire is completely mounted on the rim.

22)Tip the tool carrier arm to its non-working position.

23)Position the platform directly under the wheel and lower the spindle until the

wheel rests on the platform.

24) When the wheel is resting on the platform, check to make sure the valve is

perfectly centered with its hole. If it is not, turn the spindle slightly to adjust

the position. Fix the valve with its locking ring and remove the extension.

25) Close the arms of the spindle completely. Support the wheel to prevent it

falling off.

26) Move the platform to release the wheel from the spindle.

27) Remove the wheel.

Take the mobile control unit to work position C.

DANGER!

This operation can be extremely dangerous.

Do it manually only if you are certain you can keep the wheel

balanced.

For large and heavy tires an adequate lifting device must be used.

TIRE CHANGER FOR TRUCK TWC-1600

19

WHEELS WITH SPLIT RING BEAD BREAKING AND DEMOUNTING

WHEELS WITH 3-PIECE RINGS

1) Clamp the wheel on the spindle as described previously and check to make

sure it has been deflated.

3) Lower the tool carrier arm (14, Fig. D) to its work position until it is locked in

position by its hook.

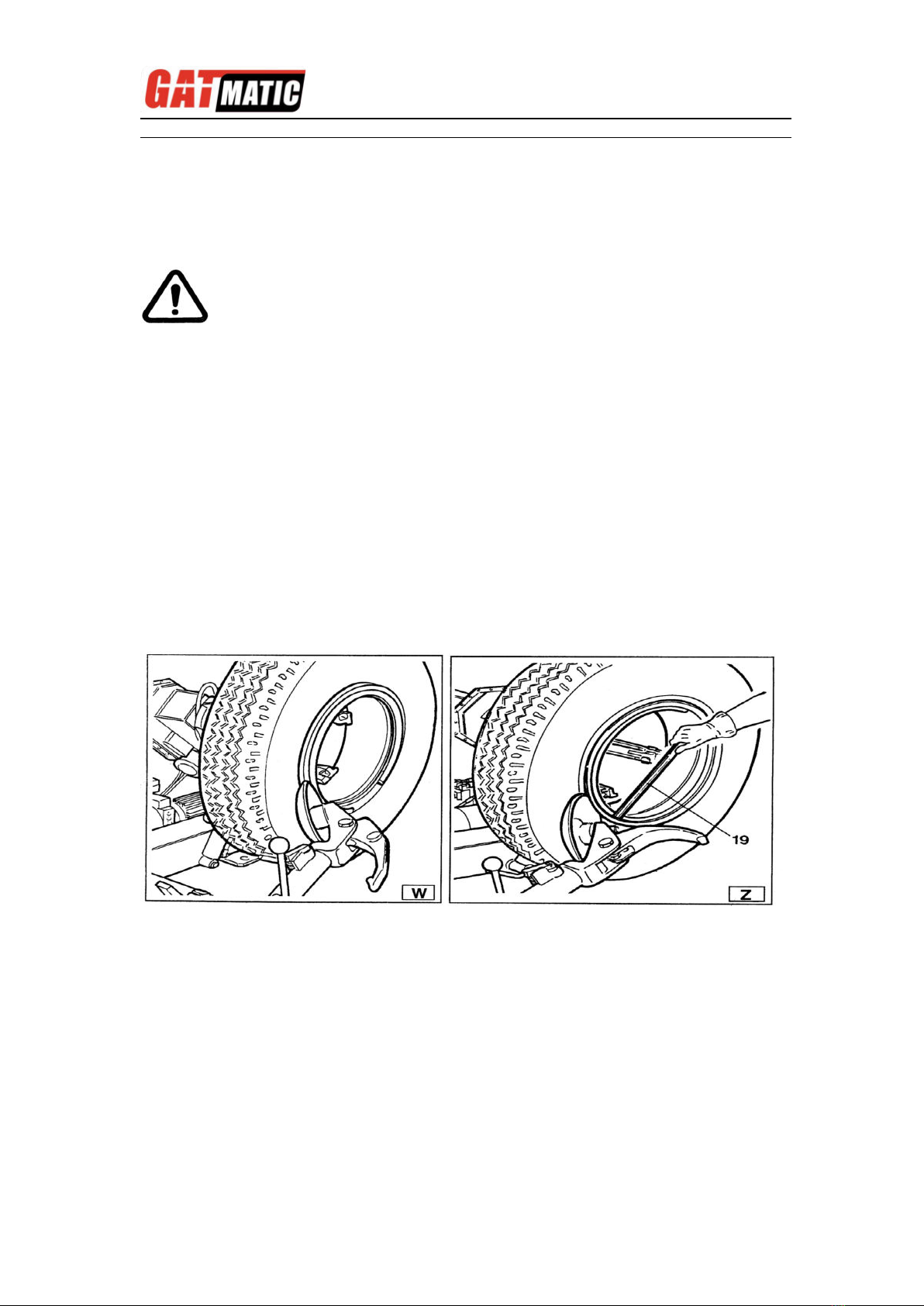

4) Position the bead loosener disk level with the rim (see Fig. W.)

5) Turn the spindle and at the same time move the disk forward a bit at a time

following the contour of the rim until the first bead is completely free (NB:

lubricate while doing this).

CAUTION! If the tire has an inner tube, work very carefully and be prepared to

stop the disk immediately once the bead has been broken so as not to damage

the valve and the inner tube.

6) Repeat this procedure but this time bring the disk against the split-ring (see

Fig. Z) until the lock ring is freed. Remove this with the special lever TL (19

Fig. Z) or with the help of the disk.

7) Remove the split-ring.

8) Move the tool carrier arm (14 Fig. D) back from the edge of the rim. Release

the hook and tip the arm to its non-working position.

Move the tool carrier arm to the inside plane of the wheel.

9) Press lever (19 Fig. D) and turn the tool head 180º which will automatically

lock in this position. Lower the arm to its working position.

10)Turn the spindle and at the same time bring the bead loosener disk up

against the tire following the contour of the split-ring until the second bead

has been broken(NB: Lubricate during this process).Continue to move

the disk forward until about half the tire has demounted from the rim(see Fig.

K).

11) Move the tool carrier arm to its non-working position.

12) Move the platform(4 Fig. A) directly under the wheel .

2) Take the mobile control unit to work position B.

Table of contents