Table Of Contents

INTRODUCTION ..........................................................................................................................................I

About this guide ....................................................................................................................................I

Contents.................................................................................................................................................I

1. PRODUCT OVERVIEW......................................................................................................................1-1

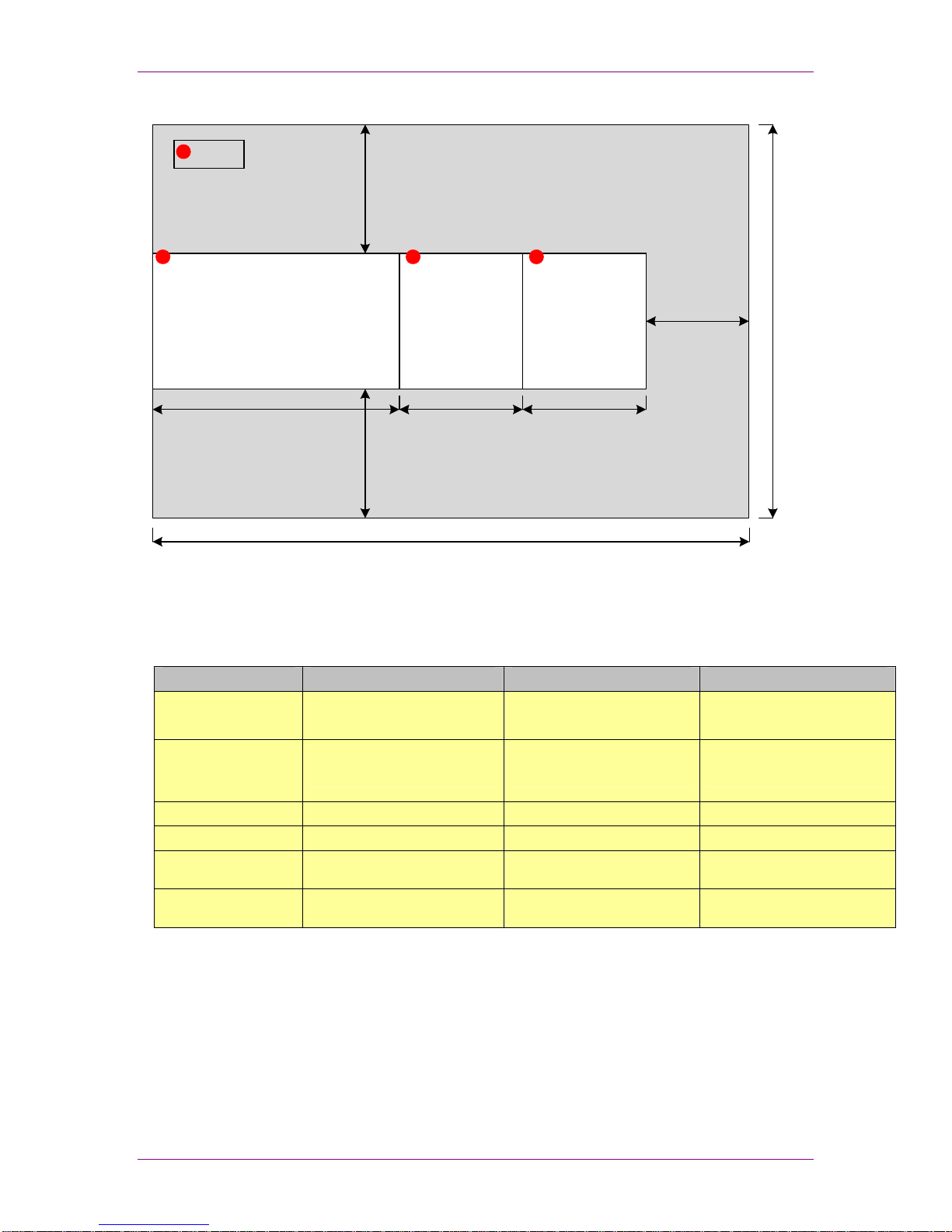

Install Planning..................................................................................................................................1-2

Device Configurations..................................................................................................................1-2

Space Requirements....................................................................................................................1-2

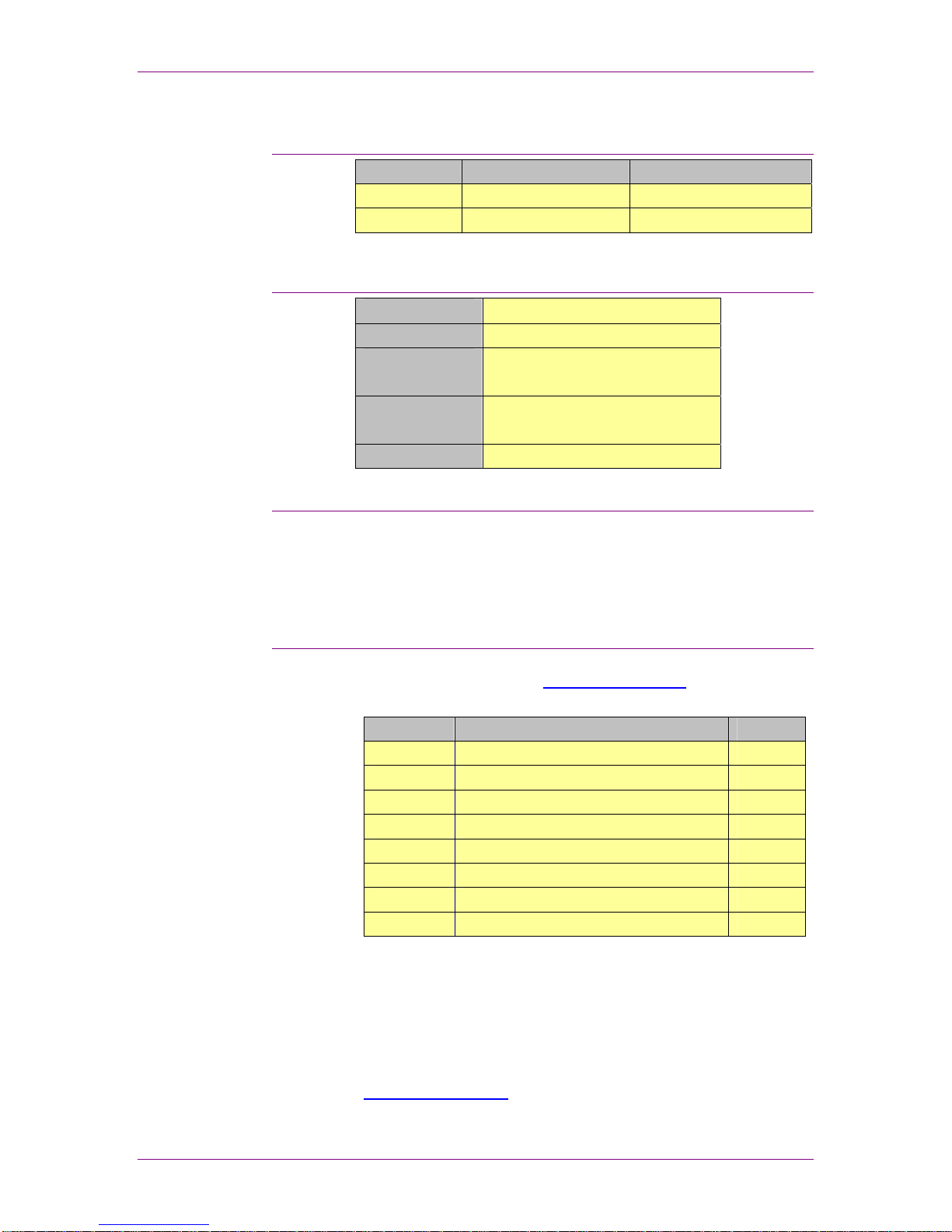

Electrical Requirements...............................................................................................................1-4

Environmental Requirements......................................................................................................1-4

Estimated Installation Time.........................................................................................................1-4

Operating Supplies....................................................................................................................... 1-4

Floor Load......................................................................................................................................1-5

Floor Level.....................................................................................................................................1-5

Unique Features Set ........................................................................................................................1-6

2. XEROX DOCUTECH 61XX................................................................................................................2-1

Performance Specifications.............................................................................................................2-1

Limitations..........................................................................................................................................2-1

System Dependencies and Prerequisites..................................................................................... 2-2

Configuration Guide..........................................................................................................................2-2

Productivity Guide............................................................................................................................. 2-2

3. XEROX IGEN3®DIGITAL PRODUCTION PRESS..............................................................................3-1

Performance Specifications.............................................................................................................3-1

Limitations..........................................................................................................................................3-1

System Dependencies and Prerequisites..................................................................................... 3-1

Configuration Guide..........................................................................................................................3-2

Productivity Guide............................................................................................................................. 3-2

4. XEROX NUVERA™100 / 120 DIGITAL PRODUCTION SYSTEM.......................................................4-1

Performance Specifications.............................................................................................................4-1

Limitations..........................................................................................................................................4-1

System Dependencies and Prerequisites..................................................................................... 4-2

Configuration Guide..........................................................................................................................4-2

Productivity Guide............................................................................................................................. 4-2

5. XEROX DOCUCOLOR 6060 / 7000 / 8000 DIGITAL COLOR PRESS..............................................5-1

Performance Specifications.............................................................................................................5-1

Limitations..........................................................................................................................................5-1

System Dependencies and Prerequisites..................................................................................... 5-2

Configuration Guide..........................................................................................................................5-2

Productivity Guide............................................................................................................................. 5-2

6. CUSTOMER AGREEMENT FORM......................................................................................................6-1

Devices...........................................................................................................................................6-1

Primary Customer Applications.................................................................................................. 6-1

Special Considerations / Limitations..........................................................................................6-1

I