Version : 9.0

2

Table of Contents

Chapter 1:Overview ..................................................................................................................... 3

1.1 Introduction ......................................................................................................................... 3

Chapter 2:Mechanical System ................................................................................................. 4

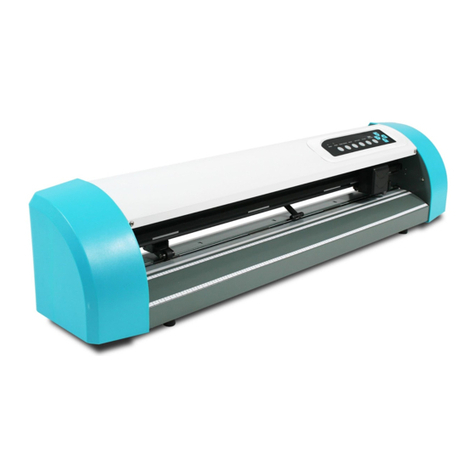

2.1 Main Unit Assembly ........................................................................................................... 5

2.2 Left End Assembly ............................................................................................................. 8

2.3 Right End Assembly ........................................................................................................ 10

2.4 Motor Bracket and Belt Assembly ................................................................................. 12

2.5 Carriage Assembly ........................................................................................................... 14

2.6 LX Carriage Assembly (AAS) ......................................................................................... 16

2.7 Pinch Roller Assembly .................................................................................................... 19

2.8 Main Beam Assembly ...................................................................................................... 21

2.9 Drum Assembly ................................................................................................................ 23

Chapter 3:Circuit System ........................................................................................................ 25

3.1 System Diagram ............................................................................................................... 25

3.2 J5 Wiring Diagram ........................................................................................................... 25

Chpater 4 Maintenance ............................................................................................................... 28

4.1 Components Replacement and Belt Tension Adjustment ......................................... 28

4.1.1 Removing the Front, Back, End and Top Covers ............................................. 28

4.1.2 Replacing the Pinch Roller Sets ......................................................................... 30

4.1.3 Replacing the Tool Carriage ............................................................................... 32

4.1.4 Replacing the

Y-Motor

.......................................................................................... 36

4.1.5 Replacing the VCM PC Board............................................................................. 38

4.1.6 Main board Connection or Replacement ........................................................... 39

4.1.7 Replacement

of Fuses ......................................................................................... 39

4.1.8 Adjusting the Tool Carriage

Transmission Belt

................................................. 40

4.1.9 Adjusting the X Motor Tension Belt .................................................................... 41

4.1.10 Adjusting the Y Motor Tension Belt .................................................................. 42

Chapter 5. Troubleshooting ....................................................................................................... 44

5.1 Maintenance Diagnostics ................................................................................................ 44

5.1.1 How to Begin

Maintenance Diagnostics

............................................................ 44

5.1.2 Diagnostic Test for SRAM and DRAM ............................................................. 46

5.1.3 Diagnostic Test for Lever Sensor .................................................................... 46

5.1.4 Diagnostic Test for Media Sensors .................................................................. 47

5.1.5 Diagnostic Test for Width Sensor .................................................................... 48

5.1.6 Diagnostic Test for Motor Encoder and Tool Holder Encoder ..................... 49

5.1.7 Y Motor Encoder Test ....................................................................................... 50

5.1.8 Diagnostic Test for Tool Force (VCM) ............................................................ 50

5.1.9 Diagnostic Test for Motor Movement .............................................................. 50

5.1.10 Diagnostic Test for the RS-232 Interface ........................................................ 52

5.2 Problems and Solutions .................................................................................................. 53

5.3 Firmware update .............................................................................................................. 56

Chapter 6 Appendix ..................................................................................................................... 58

6.1 Recommended Parts and Accessory List .................................................................... 58