2

Contents

Important

Safety

Information

.......................................................1

Safety Instructions........................................................................................................ 1

General and Personal Safety Precautions …..................................................................1

Contents

.........................................................................................2

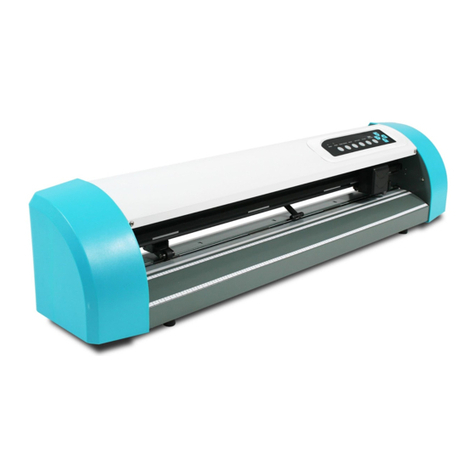

Introduction and Component Overview..........................................................................3

Main Unit Assembly……………................................................................................4

Unit Chassis Assembly .................................................................................................6

Left End Assembly..........................................................................................................7

Right End Assembly ......................................................................................................9

Carriage Assembly without PCB…..............................................................................11

Complete X-motor Assembly........................................................................................13

Y-Axis Idle Pulley Assembly........................................................................................15

Pinch Roller Assembly..................................................................................................17

Grid Drums Assembly...................................................................................................19

Main Beam Assembly………………………………………………………………...21

1. System

Diagram

and

Components

of

Main

Board

................22

1.1 System Diagram………………………………………………………………..23

1.2 Connection of Electrical Components…………………………………………24

Replacement of Pinch Roller Set and Lever Assembly............................................26

Removal and installation of Tool Carriage……………….............................................28

Belt Tension Adjustment……………........................................................................29

2. Maintenance………………………………………………………..30

Removing the Front, Back, End and Top Covers…………………………………..30

Replacing the Pinch Roller Sets…...............................................................................32

Replacing the Tool Carriage………………………………………………………...34

Replacing the Y-Motor................................................................................................36

Replacing the VCM PC Board.....................................................................................38

Main board Connection or Replacement ................................................................…39

Replacement of Fuses ............................................................................................….40

Adjusting the Tool Carriage Transmission Belt...........................................................41

Adjusting the X Motor Tension Belt............................................................................42

Adjusting the Y Motor Tension Belt............................................................................43

3.T

r

oubleshooting…………………………………………………..45

Maintenance Diagnostics.............................................................................................45

How to Begin Maintenance Diagnostics......................................................................46

Diagnostic Test for SRAM and DRAM.......................................................................47

Diagnostic Test for Lever Sensor.................................................................................47

Diagnostic Test for Media Sensor…………………....................................................48

Diagnostic Test for Width Sensor ................................................................................49

Diagnostic Test for Motor Encoder and Tool Holder Encoder ...................................50

Diagnostic Test for Tool Force (VCM).......................................................................51

Diagnostic Test for Motor Movement.........................................................................51

Diagnostic Test for the RS-232 Interface....................................................................53

Problems and Solutions...............................................................................................54

Appendix

………………………………………………………..……57

Spare Parts Reordering Form...............................................................................58