1

INSTALLATION INSTRUCTIONS

Servicenter™mini-unit substation

Three-phase 22.5 kVA models

Receiving

Upon receipt of shipment, examine the

package for any damage that may have

occurred in transit. While unpacking,

examine the unit for broken, bent, loose

parts, or other damage. If injury from

outside sources is evident, file a damage

claim with the transportation company

and notify the nearest sales office.

Storage and handling

The storage area should be clean. Before

placing the unit in service after a period of

storage, be sure it is clean and dry by

observing the instruction under

“Installation”. The unit may be fork truck

lifted or raised by the lifting holes located

on the top core clamps under the

transformer cover.

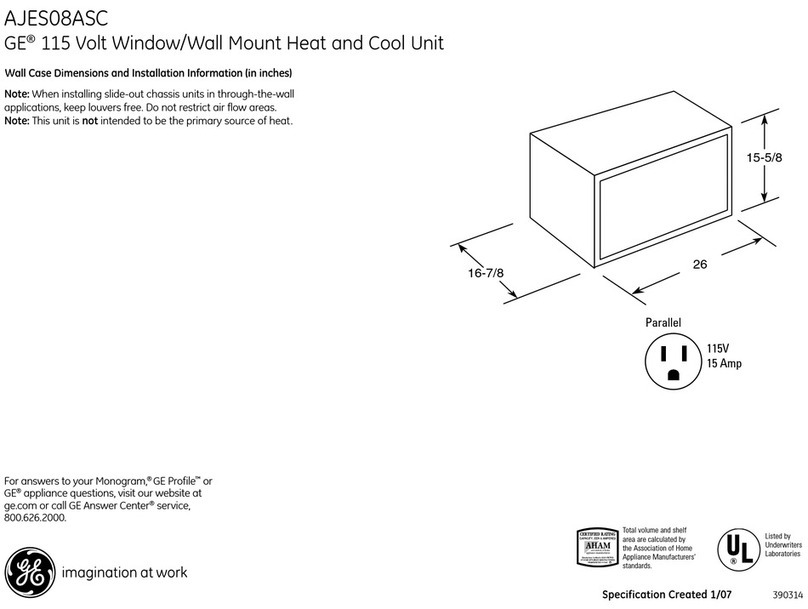

Installation preparation and mounting

If the interior moisture is evident by the

appearance of rust, the unit should be

dried. Megger readings of 10 Megohms

minimum should be obtained before

installation. Free circulation of air is

essential for proper operation of the unit.

The servicenter will perform at its rated

output when surrounding air does not

exceed 40 °C (105 °F) and adjacent

structures permit free movement of

cooling air. The unit must be mounted

upright.

Connections

NOTE: Do not make or change

connections while unit is

energized!

The unit must be mounted upright.

Reference should be made to the wiring

diagram (Figure 1) when making

connections.

A new grounding electrode conductor is to

be connected to the neutral bar of the

secondary in accordance with the National

Electrical Code.

If a primary terminal strip is bonded to the

enclosure by means of the neutral bonding

screw, it may be removed for special

applications.

Make certain that all connections are

electrically tight to prevent joint heating.

If aluminum cable is used, adequate

preparation of the aluminum cable and

protection of the joint is essential.

Secondary branch circuit breaker ampere

ratings and branch circuit conductor sizes

must be selected in accordance with the

National Electrical Code.

The servicenter is factory connected on

the primary side for the nominal rated

three-phase delta connected input

voltage. If the primary input voltage is

other than nominal, the transformer taps

may be adjusted in accordance with

instructions provided with the

transformer.

The primary main breaker and the

secondary main breaker may be changed

using breakers of equal voltage ratings

and “equal to” or “lower” current ratings.

However, the use of primary breakers with

current ratings lower than those supplied

may result in nuisance tripping. This is due

to in-rush currents in the primary winding

which occur when the transformer is

energized.

NOTE: Primary and secondary

breakers with current ratings

higher than those supplied must

not be used.

After all electrical connections have been

made and the required branch circuit

breakers installed, the inside metal cover

plate must have the corresponding branch

circuit breaker knockouts removed and

the cover-plate reinstalled. Fasten the

cover-plate in place, being sure that no

cables are caught between the cover-plate

and the framework. Also, ensure that all

breakers are aligned with the knock-out

holes in the cover-plate. Branch circuit

positions should be recorded on the

identification labels provided.

—

Servicenter mini-unit substation