Everest Ca-Zoom®6.2

1. Warning and Precautions...................... 3

.

2. System Symbol Description ................. 7

3. Features and Benefits .......................... 8

4. Applications ...........................................8

5. Helpful Hints .......................................... 9

6. System Overview .................................. 9

6.1 System .......................................... 9

6.2 Standard System .........................10

6.3 Optional Component ....................10

7. System Components ...........................11

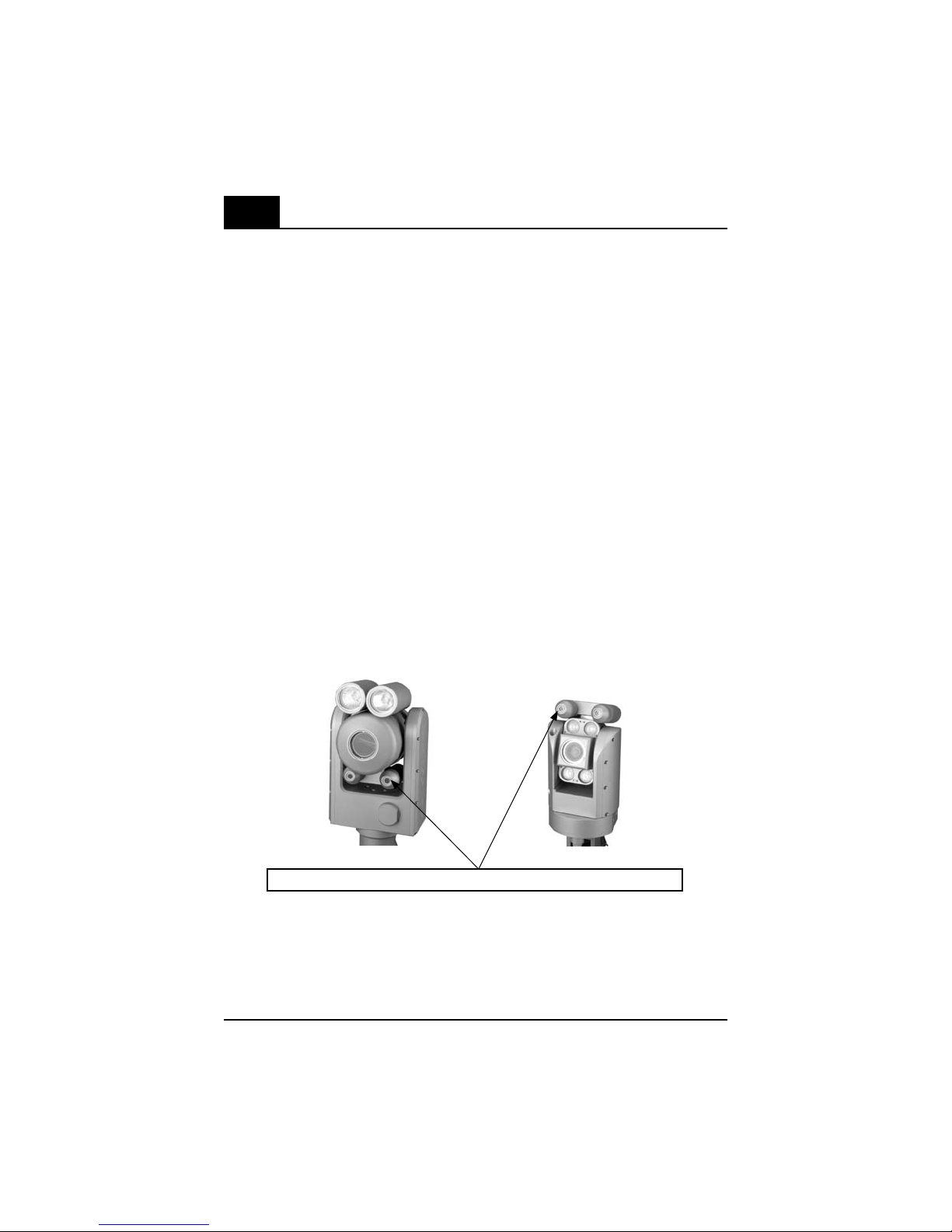

7.1 Camera Control Unit ....................11

7.2 Camera Head .........................11-12

7.3 Hand-held Controller ..................12

8. System Setup ......................................13

8.1 Attaching HH Controller Cable.....13

8.2 Attaching the Camera Cable........14

8.3 Attaching Strain Relief Cable .....14

8.4 Attaching Slip Ring Cable

Reel ............................................15

8.5 Attaching other PeripheralDevices.15

8.6 System Power ............................15

8.7 Laser Installation PTZ100............16

8.8 Laser Installation PTZ140............17

9. Operation Procedures ....................... 18

10. Hand-Held Controls ...........................19

11. Menu Features .................................. 27

11.1 SAVE IMAGE ................................ 27

11.2 ANNOTATION ............................... 29

12. Main Menu Operation ......................

36

12.1 GO TO HOME................................37

12.2 CAMERA SETUP Menu ................37

12.3 LASERS ..................................... 43

12.4 POSITIONS ................................. 43

12.5 SPLIT SCREEN ............................45

12.6 VIDEO RECORD ...........................48

12.7 FILE MANAGER Menu ................

50

12.8 SETUP Menu .............................

58

Table of Contents

13. Measurement Operations ............... 67

14. Maintenance ......................................71

14.1 Cleaning .................................... 71

14.2 Storage & Shipment .................. 71

14.3 Lamp & Lamp Window

Replacement - PTZ140............... 71

14.4 Camera Window

Replacement - PTZ140............... 72

14.5 Camera Module

Replacement - PTZ140...............73

14.6 Lamp Window

Replacement - PTZ100............... 75

14.7 Camera Window

Replacement - PTZ100.............. 76

14.8 Camera Module

Replacement - PTZ100...............77

14.9 Lamp Replacement - PTZ70...... 79

14.10 Camera Window

Replacement - PTZ70................ 80

14.11 Camera Module

Replacement - PTZ70.................81

14.12 Purging ....................................... 82

14.13 Pressure testing .........................82

15. Troubleshooting ............................... 83

16. Service .............................................. 84

17. Warranty............................................. 85

18. Appendices ........................................86

A - Specifications ...............................86

B - Software......................................... 90

C - Legacy ......................................... 91

D - New System Default Settings.........92

E - Accessories.................................. 92

F - Manual Image Control Features......93

G - Laser Accessory Calibration ..........94

H - Agency Certification..................... 96

I - System Configuration (w/cable)......97

J - System Configuration (no cable).....98

K - Spare Part List ..............................99

L - Chemical Compatibility.................101

M - Creating a Logo Bitmap File ........102

N - Environmental Compliance ........ 103

2