– 3 –

Table of Contents

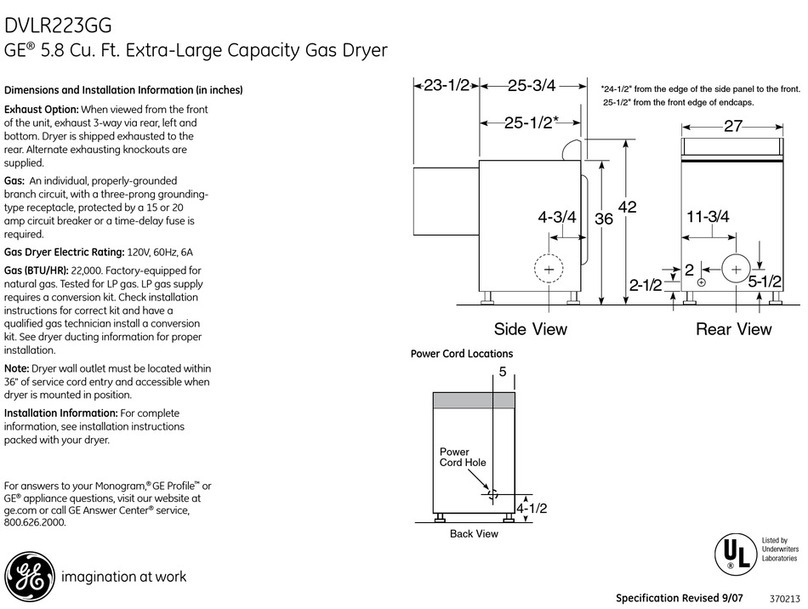

Air Duct Assembly ............................................................................................................................................................14

Belt Switch............................................................................................................................................................................18

Blower Motor ......................................................................................................................................................................19

Blower Wheel......................................................................................................................................................................21

Burner Assembly and LP Conversion......................................................................................................................25

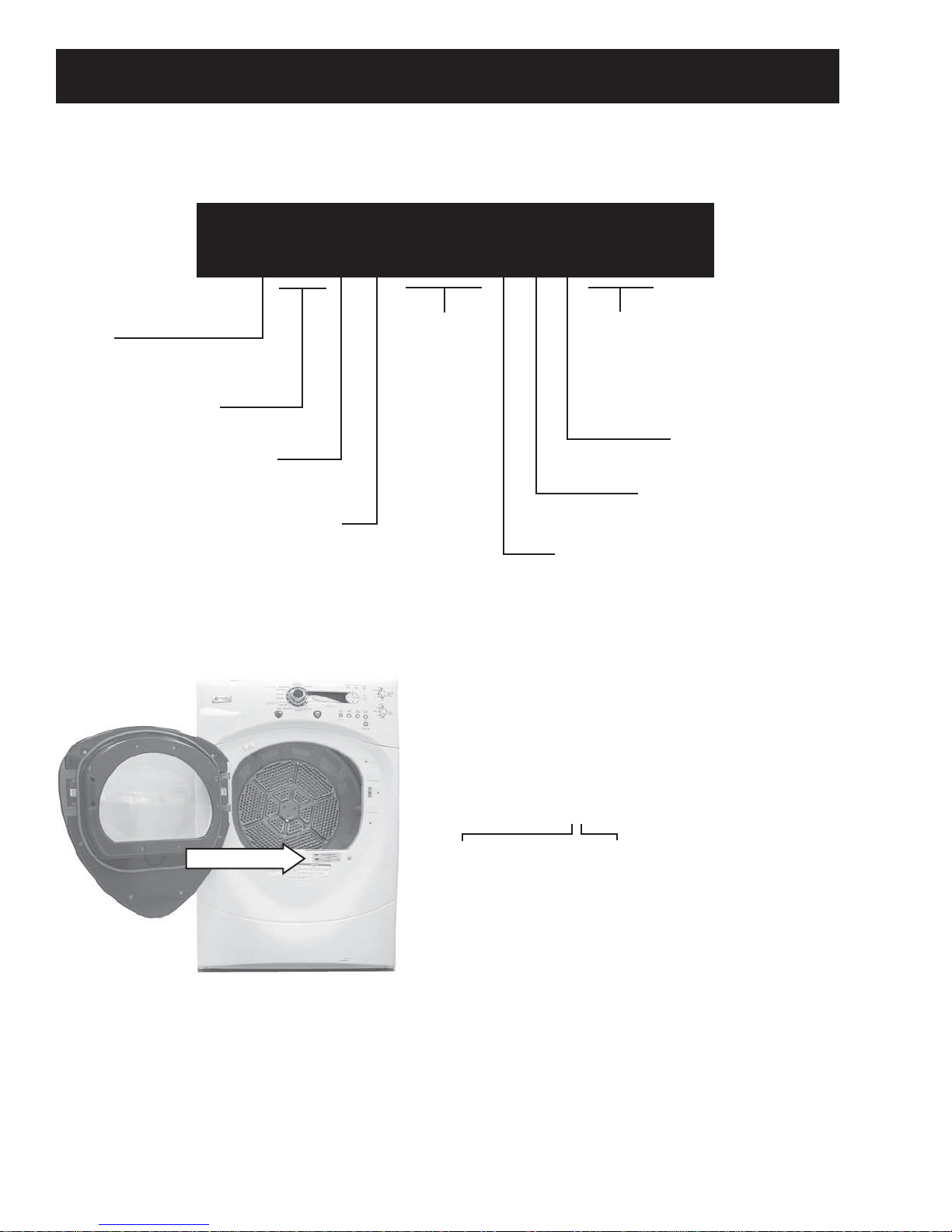

Component Locator Views........................................................................................................................................... 8

Control Board Assembly ...............................................................................................................................................33

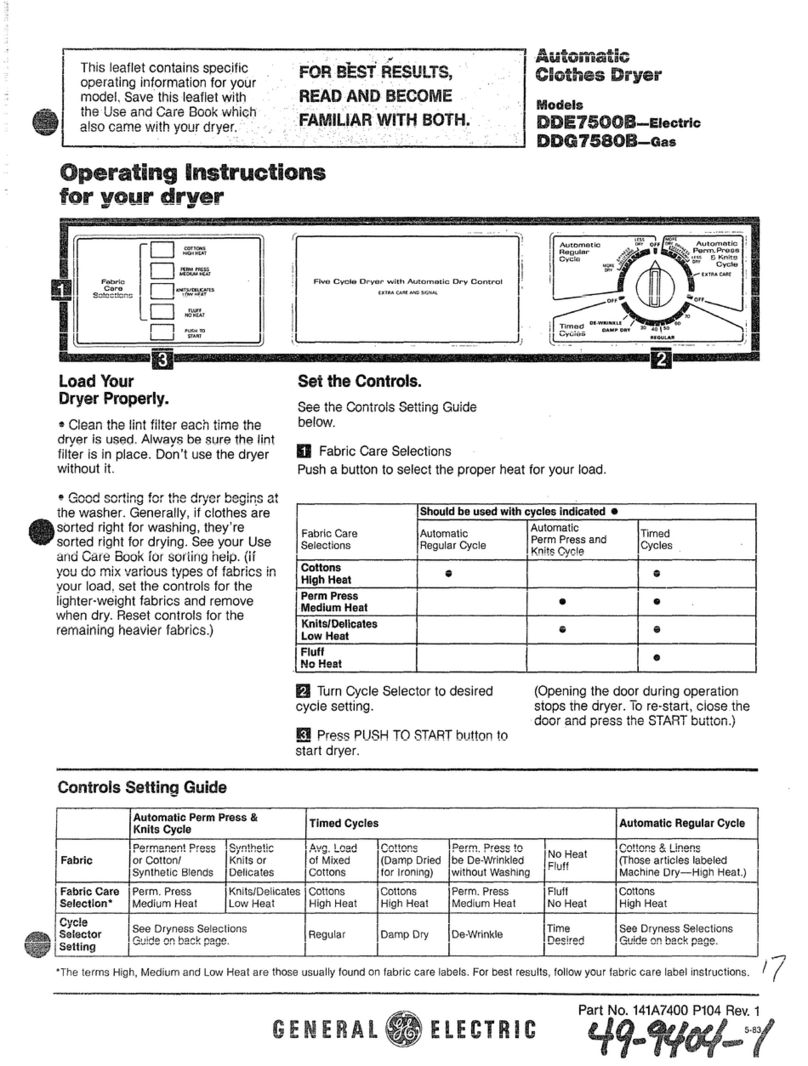

Control Features............................................................................................................................................................... 6

Control Panel.......................................................................................................................................................................12

Display Board.....................................................................................................................................................................34

Door Switch ......................................................................................................................................................................... 15

Drive Belt...............................................................................................................................................................................16

Drum.......................................................................................................................................................................................17

Drum Motor.........................................................................................................................................................................18

Drum Shaft and Bearing................................................................................................................................................17

Drum Slide Assembly......................................................................................................................................................14

Dryer Components...........................................................................................................................................................12

Dual Idler Assembly.........................................................................................................................................................17

Error Codes .......................................................................................................................................................................... 43

Flame Detector ..................................................................................................................................................................27

Front Panel...........................................................................................................................................................................13

Gas Valve..............................................................................................................................................................................26

Gas Valve Coils...................................................................................................................................................................25

Heater Assembly...............................................................................................................................................................22

High Limit Thermostat....................................................................................................................................................31

Ignitor.....................................................................................................................................................................................27

Ignitor Circuit Operation................................................................................................................................................28

Inlet Control Thermistor.................................................................................................................................................30

Inlet Safety Thermostat.................................................................................................................................................30

Introduction......................................................................................................................................................................... 5

Moisture Sensor ................................................................................................................................................................15

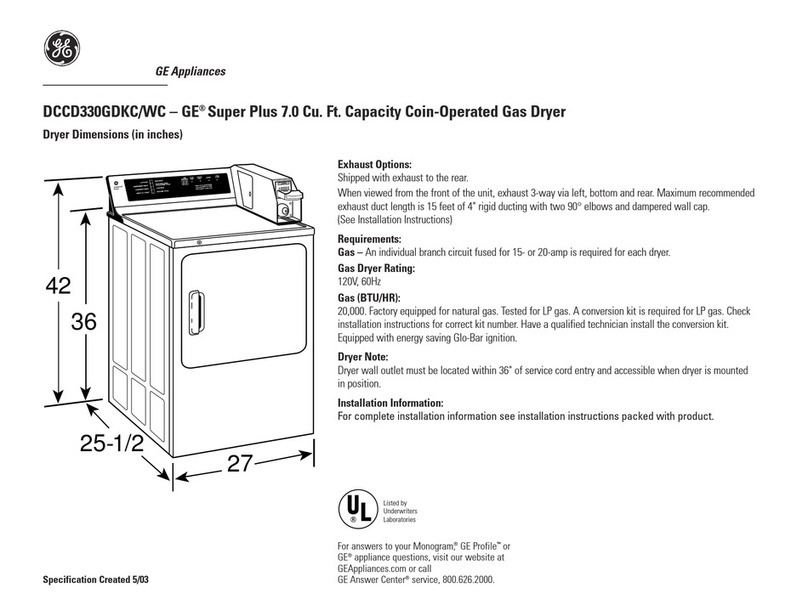

Nomenclature .................................................................................................................................................................... 4

Outlet Control Backup Thermostat...........................................................................................................................32

Outlet Control Thermistor .............................................................................................................................................31

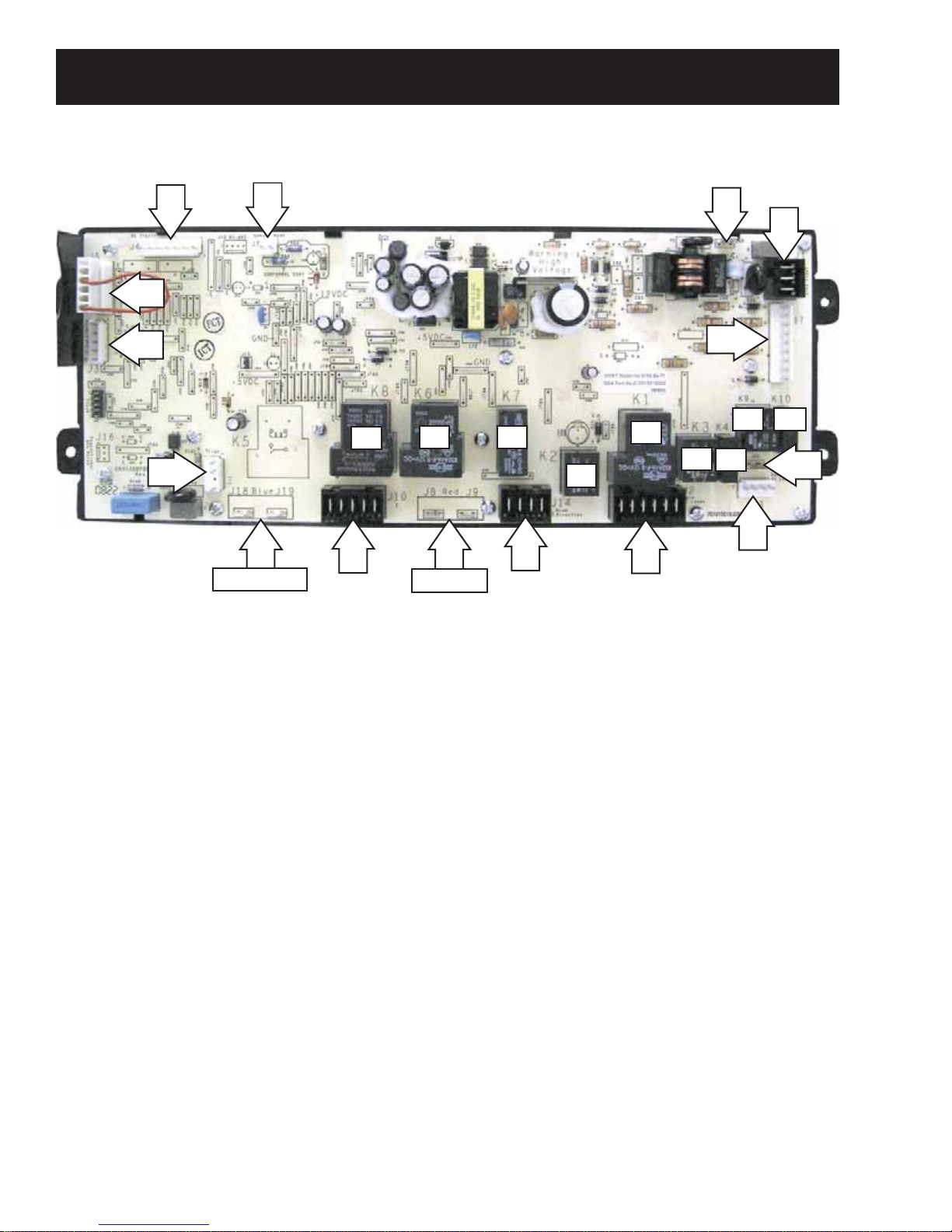

Power Board........................................................................................................................................................................33

Power Board Connector Locator View....................................................................................................................10

Rack Dry Calrod®Element ...........................................................................................................................................29

Rack Dry Thermostat......................................................................................................................................................32

Schematics and Wiring Diagrams............................................................................................................................46

Service Test Mode.............................................................................................................................................................39

Steam Components.........................................................................................................................................................35

Steam Generator Assembly.........................................................................................................................................35

Steam Interlock Relay.....................................................................................................................................................37

Top Panel ..............................................................................................................................................................................13

Triac.........................................................................................................................................................................................22

Troubleshooting ................................................................................................................................................................39

Warranty ..............................................................................................................................................................................50

Water Fill Timer..................................................................................................................................................................38

Water Valve.........................................................................................................................................................................37