IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

AWARNING'!

YOURLAUNDRYAREA

• Keep the area underneafll and around your

appliances flee of combustible mamrials, such

as lint, papeI, rags and chemicals.

• Keep the floor around your appliances clean and

d_T to reduce the possibility of slipping.

• Keep area around die exhaust opening and

surrounding areas flee flom the accumulation

of lint, dust and dirt.

• Do not obsnuct die flow of ventilating mL Do not

stuck or place laun& T or throw rugs against tile

flont or back of the d_TeL

• (]lose supervision is necessaiy if dais appliance is

used by or near children. Do not allow children

m plW on, with or inside tills or any other

appliance.

• Keep all laundI T aids (such as detergents,

bleaches, etc.) out of the reach of children,

preferably in a locked cabinet. Observe all

warnings on container labels to avoid i_ju_T.

• Never climb on or stand on die d_Ter rap.

4

WHENUSINGYOURDRYER

Never reach into the dryer while the drum is

moving. Before loading, unloading or adding

clothes, wait until the drum has completely

smpped.

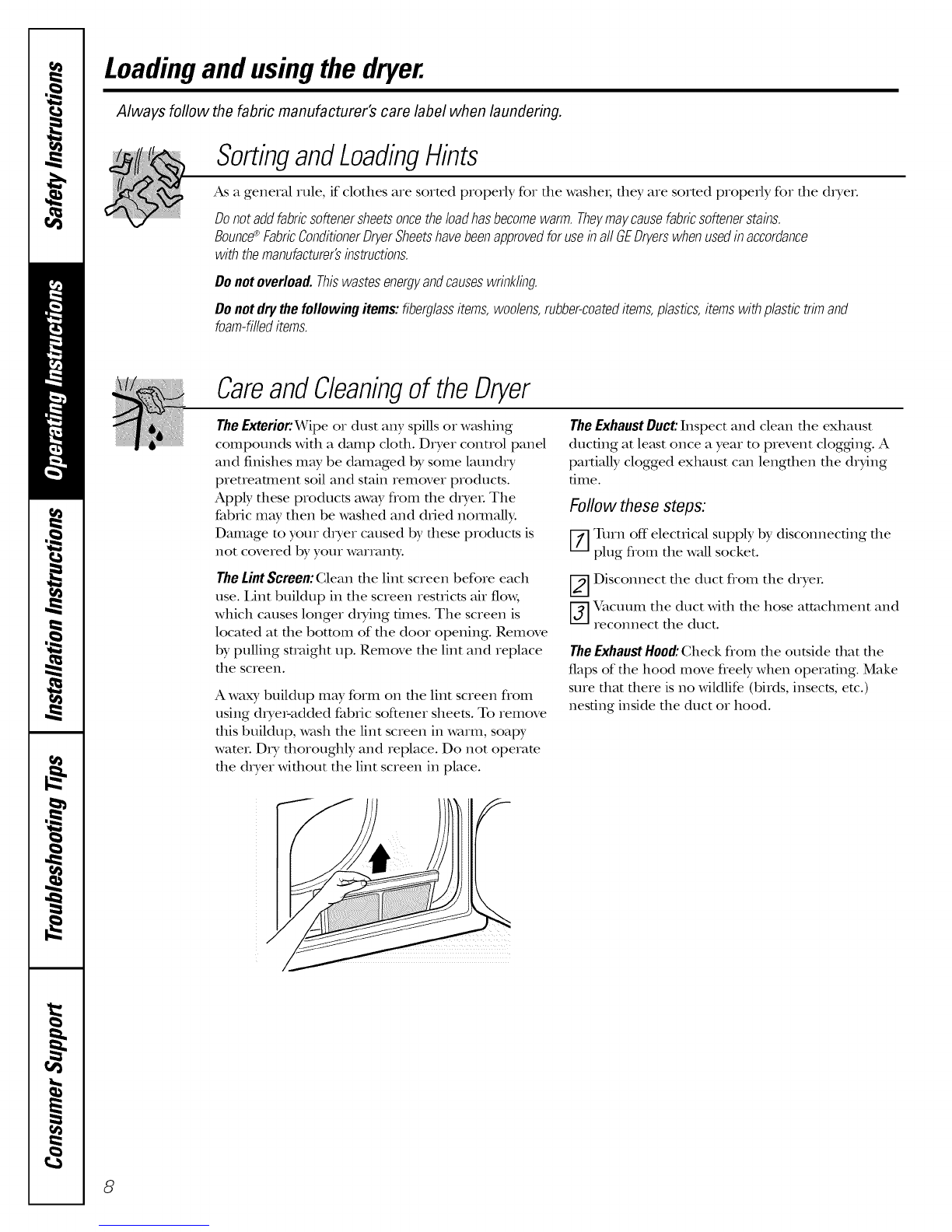

Cleanthelintfilterbeforeeachloadto prevent lint

accumulation inside the dryer or in the room.

DONOTOPERATETHEDRYERWITHOUTTHELINT

FILTERIN PLACE,UNLESSTHEDRYINGRACKISIN

USE.Ah,vays replace tile lint screen when finished

using the d_Ting rack.

• Do not dI y articles containing mbbeI, plastic

or similar mam_ials such as padded bins, mnnis

shoes, g_doshes, badl mats, rugs, bibs, baby pants,

plastic bags and pillows that may melt or burn.

Some rubber mamIials, when heated, can under

certain circumstances produce fire by

spontaneous combustion.

• Do not store plastic, paper or clodflng dmt may

burn or melt on top of the dxyer during

operation.

• Do not wash or dITarticles dmt have been

cleaned in, washed in, soaked in or spotted

with combustible or explosive substances (such _ts

wax, oil, paint, gasoline, degreaseIs, dry-cleaning

soNents, kerosene, etc.). These substances give

offvapots that m W igmim or explode. Do not add

these substances m the wash WamL Do not use or

place these substances around your washer or

d_Ter du_ing operation.

• Aalyarticle on which you have used a cleaning

sokent or dmt contains flammable mamrials

(such as cleaning cloths, mops, towels used in

beauty salons, restaurants or barber shops, etc.)

must not be placed in or near the d_Ter until

sokents or flammable materials have been

removed. There are many highly fl_umnable

imms used in homes such as acetone, denatured

alcohol, gasoline, kerosene, some household

cleaners, some spot removers, turpentines,

waxes, wax removers and products containing

peuoleum disfillams.

The laund_ T process can reduce die fl_une

remrdancy of fabrics. To avoid such a result,

careflfily follow the garment manufacturer's

care insu-ucfions.

• Garments labeled OrgAway from Hoator Do

Not Tumble Dry (such as life jackets containing

kapok) must not be put in your dryeL

• Do not dIT fiberglass articles in your dITeL

Skin iIxitafion could result flom the remaining

particles that may be picked up by clothing

du_ing subsequent d_Ter uses.

• To minimize file possibility of elecuic shock,

unplug ttlis appliance flom tile power supply

or disconnect the &yet at tile household

disuibufion panel by removing the fllse or

swimhing off the circuit breaker before

attemp6ng any maintenance or cleaning

(except the removal and cleaning of the lint

filter). NOTE: Turning the Cycle Selector knob

to an OFFposition does NOTdisconnect the

appliance from the power suppl?:

• Do not spray any type of aerosol into, on or near

d_Ter at any time.

• Do not place imms exposed to cooking oils in

your d_yer. Imms contaminamd with cooking oils

may conuibum to a chemical reaction that could

cause a clothes load m catch fire.