GE

Lumination

Installation Guide

12

Volt

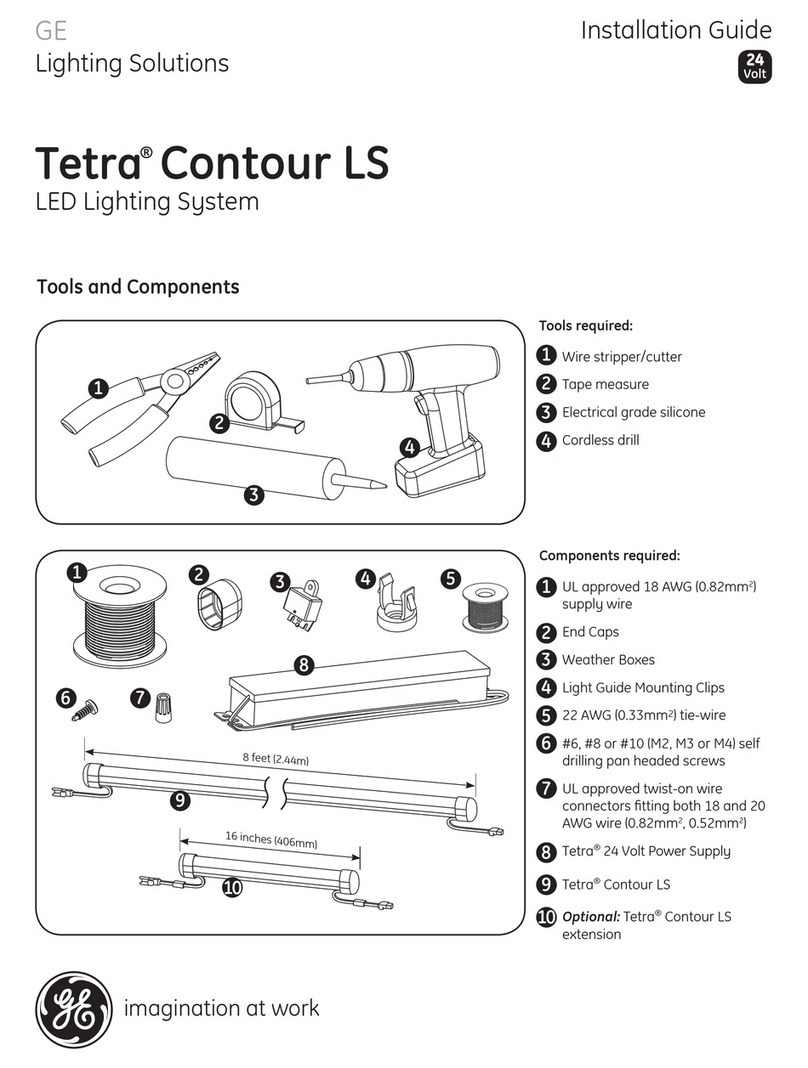

6

7

8

9

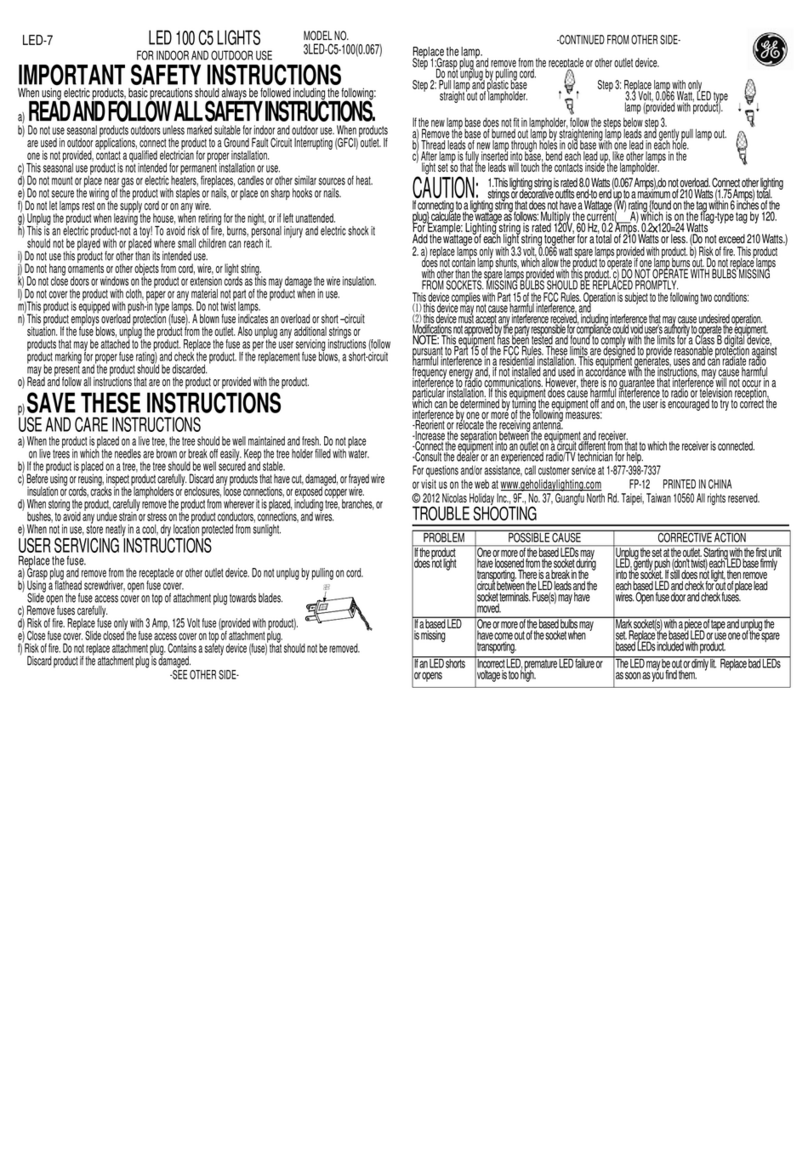

1

2

3

4

5

UL approved 18 AWG (0.82 mm2) supply wire

UL approved 22-14 AWG (0.33-2.08 mm2)

wire connectors or 22-18 AWG

(0.33-0.82 mm2) in-line/IDC connectors

#6 or #8 (M3 or M4) screws or 1/8 inch

(3.2 mm) rivets

End caps (GETMEC1)

Tetra®Power Supply (GEPS12-20,

GEPS12-60, GEPS12-60U)

Tetra®PowerStrip LED modules

(GEWHSSP3-65K, GEWWSSP3-41K)

Components

imagination at work

Tetra®PowerStrip

LED Lighting System

6180 Halle Drive • Valley View, Ohio 44125-4635 • USA

P: 216.606.6555 • F: 216.606.6599 • www.led.com • info@led.com

Lumination, LLC is a subsidiary of the General Electric Company. Tetra is a trademark of Lumination, LLC. The GE brand, logo, and ecomagination are trademarks of the General Electric Company.

© 2009 Lumination, LLC. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

SIGN066-R060909

For customer service & technical support, contact:

1-888-MY-GE-LED (1.888.694.3533)

(GEWHSSP3-65K, GEWWSSP3-41K)

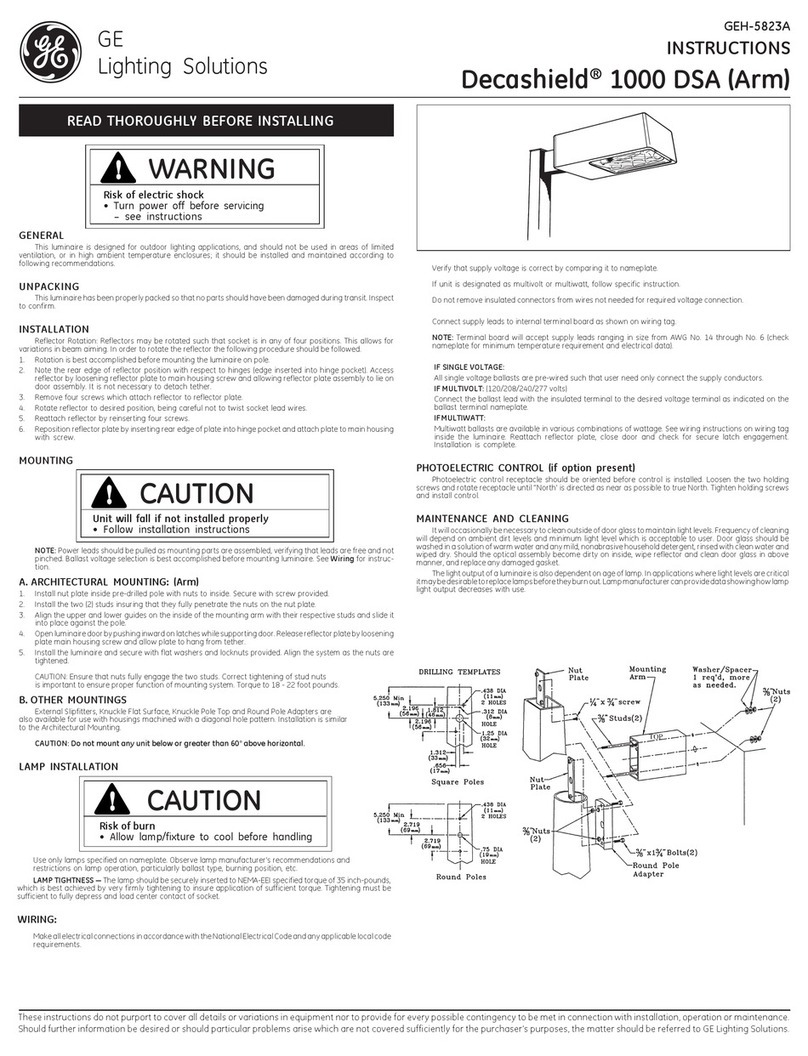

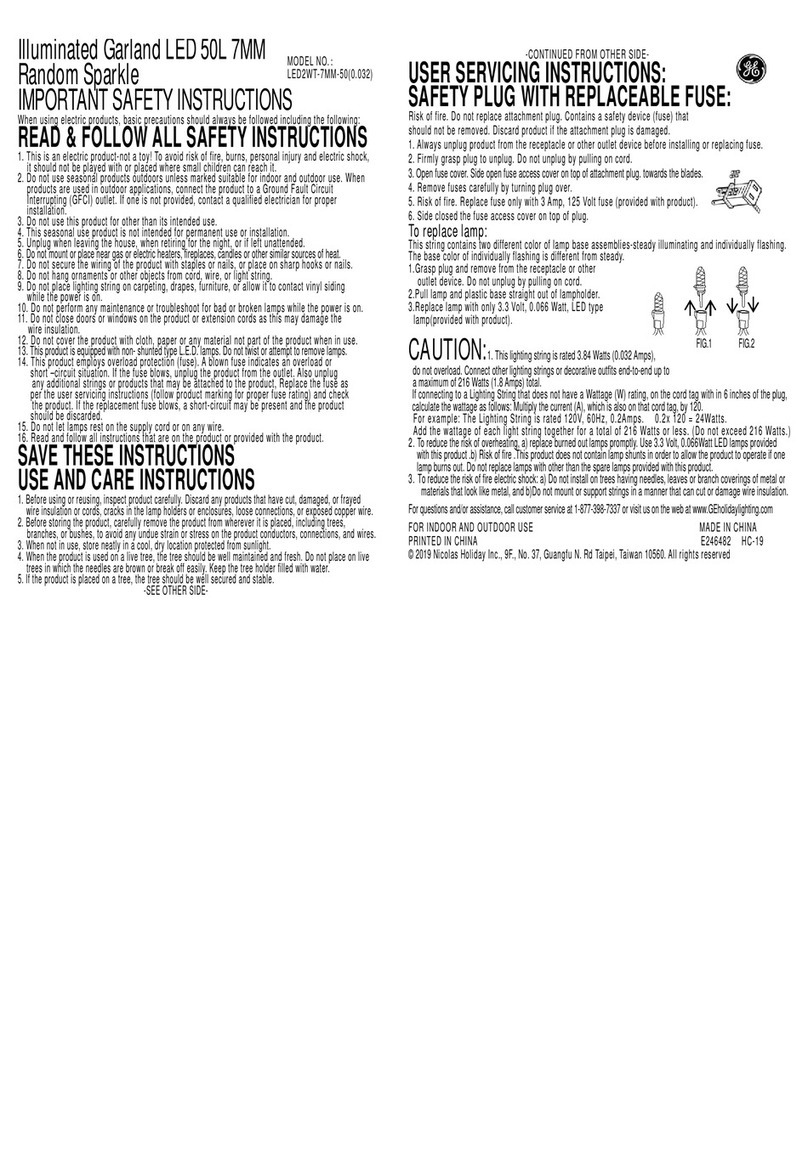

RISK OF ELECTRIC SHOCK:

• Turn power OFF before inspection, installation

or removal.

• Properly ground Tetra Power Supply enclosure.

RISK OF FIRE:

• Follow all NEC and local codes.

• Use only UL approved wire for input/output

connections. Minimum size 18 AWG (0.82 mm2)

WARNING!

Conforms to the following standards:

Prepare Electrical Wiring

Electrical Requirements

• Do not use in wet locations.

• The grounding and bonding of the LED

Driver shall be done in accordance with

National Electric Code (NEC) Article 600.

• Follow all National Electric Codes (NEC) and

local codes.

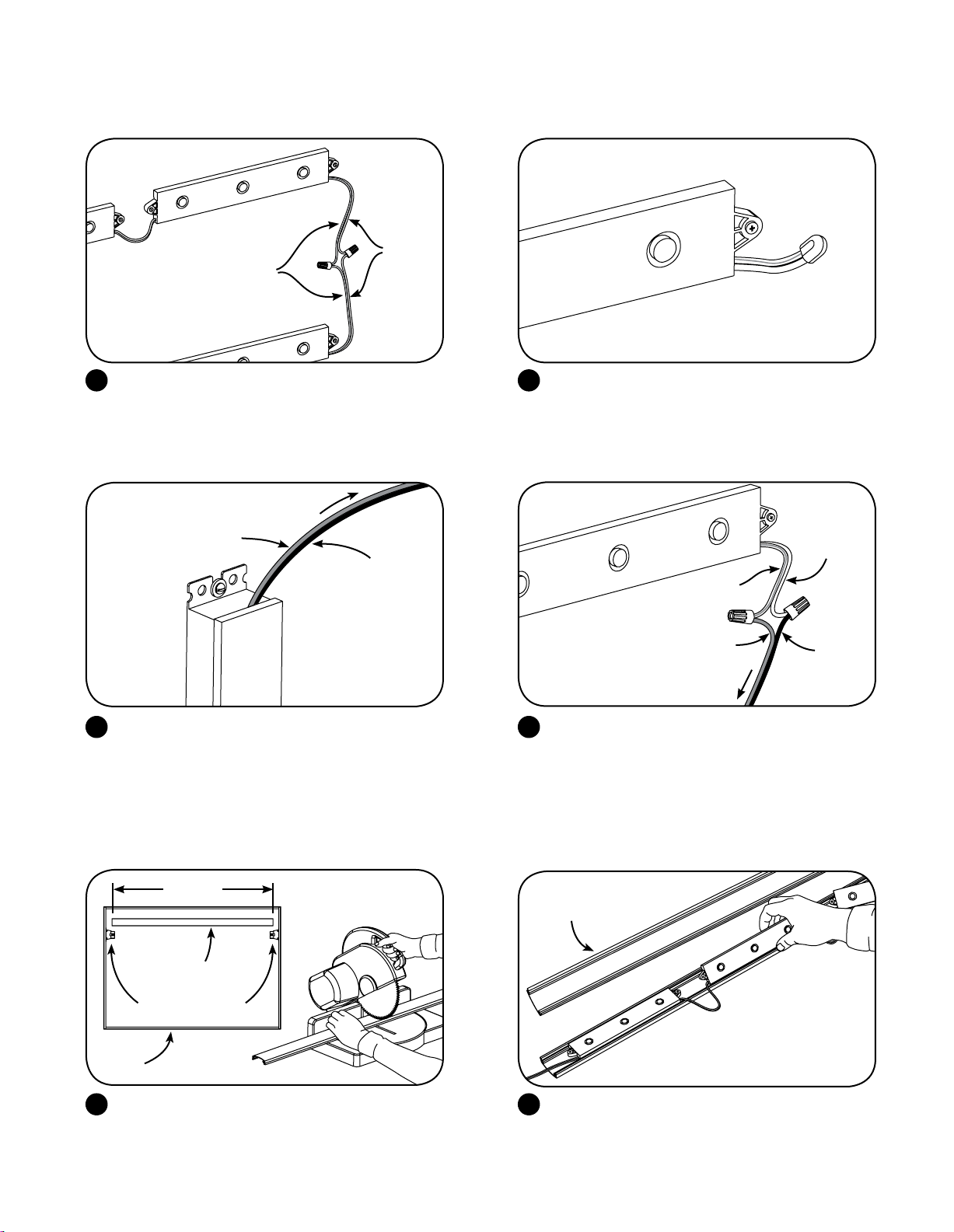

Symptom Solution

Row of modules does

not light • Check wire connections to power supply to ensure red stripe-to-red and white-to-black connections.

• Check row-to-row polarity connections.

Sign does not light • Check input and output voltage and check power supply input/output connections.

• Check polarity connections.

Individual modules

do not light

• Remove module and replace with another working module.

Modules are dim • Ensure the overall length of the Tetra®LED system does not exceed the maximum load.

• Ensure the length and gauge of the supply wire is equal to or below the recommended remote

mounting distance.

Troubleshooting

Tetra®PowerStrip Assembly Support

(GEDSAS1)

Tetra® PowerStrip Tube Connector (GEDSTC1)

Tetra® PowerStrip Assembly End Cap

(GEDSMB1)

Tetra® PowerStrip Tube (GEDSAT96)

OPTIONAL

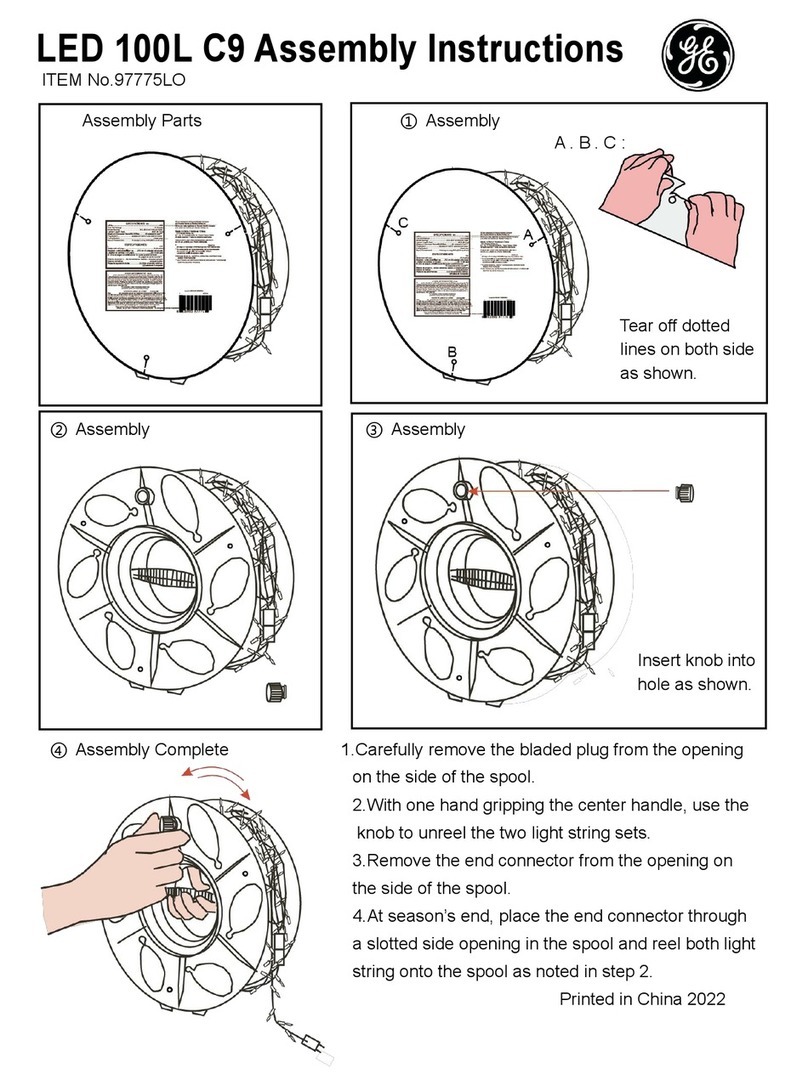

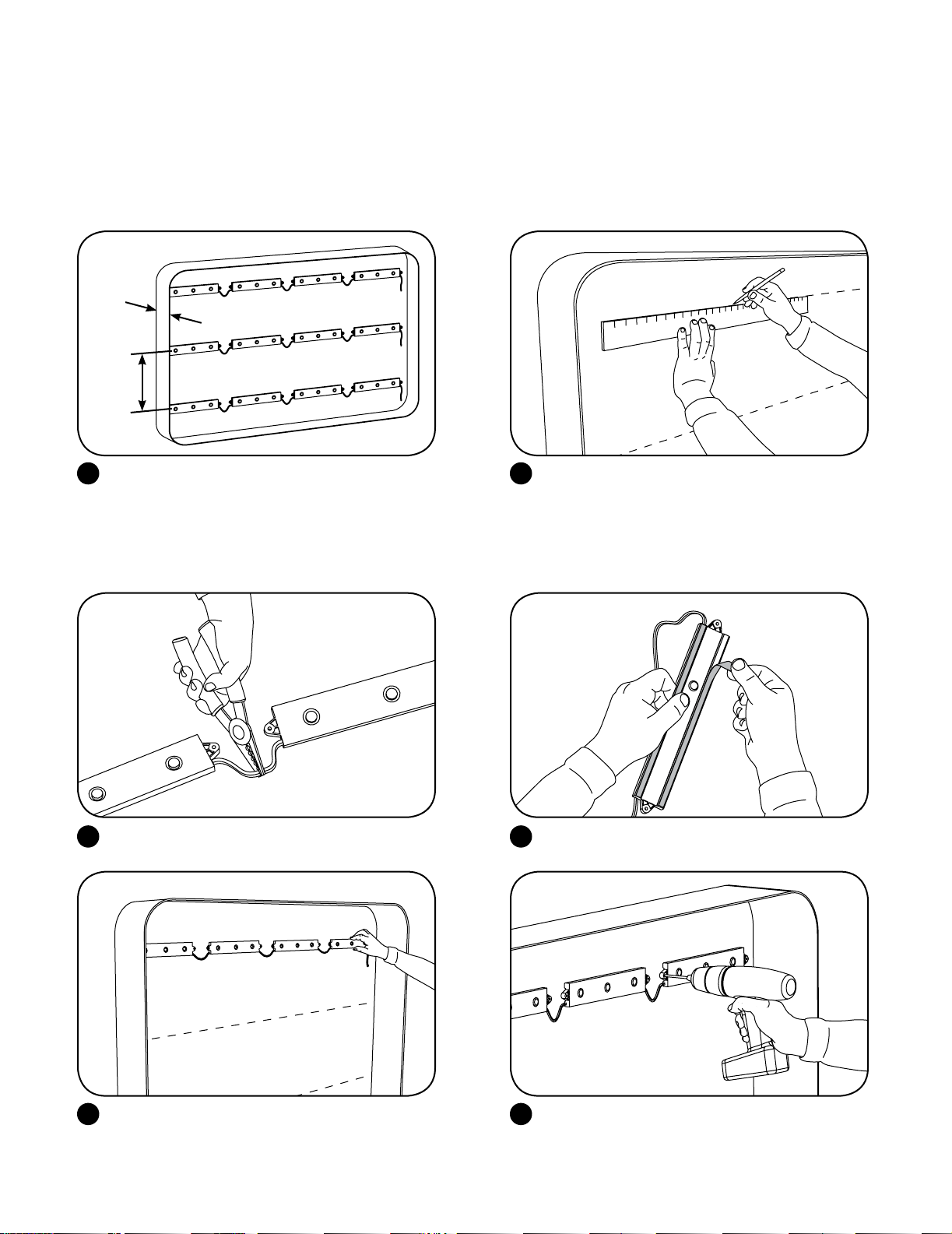

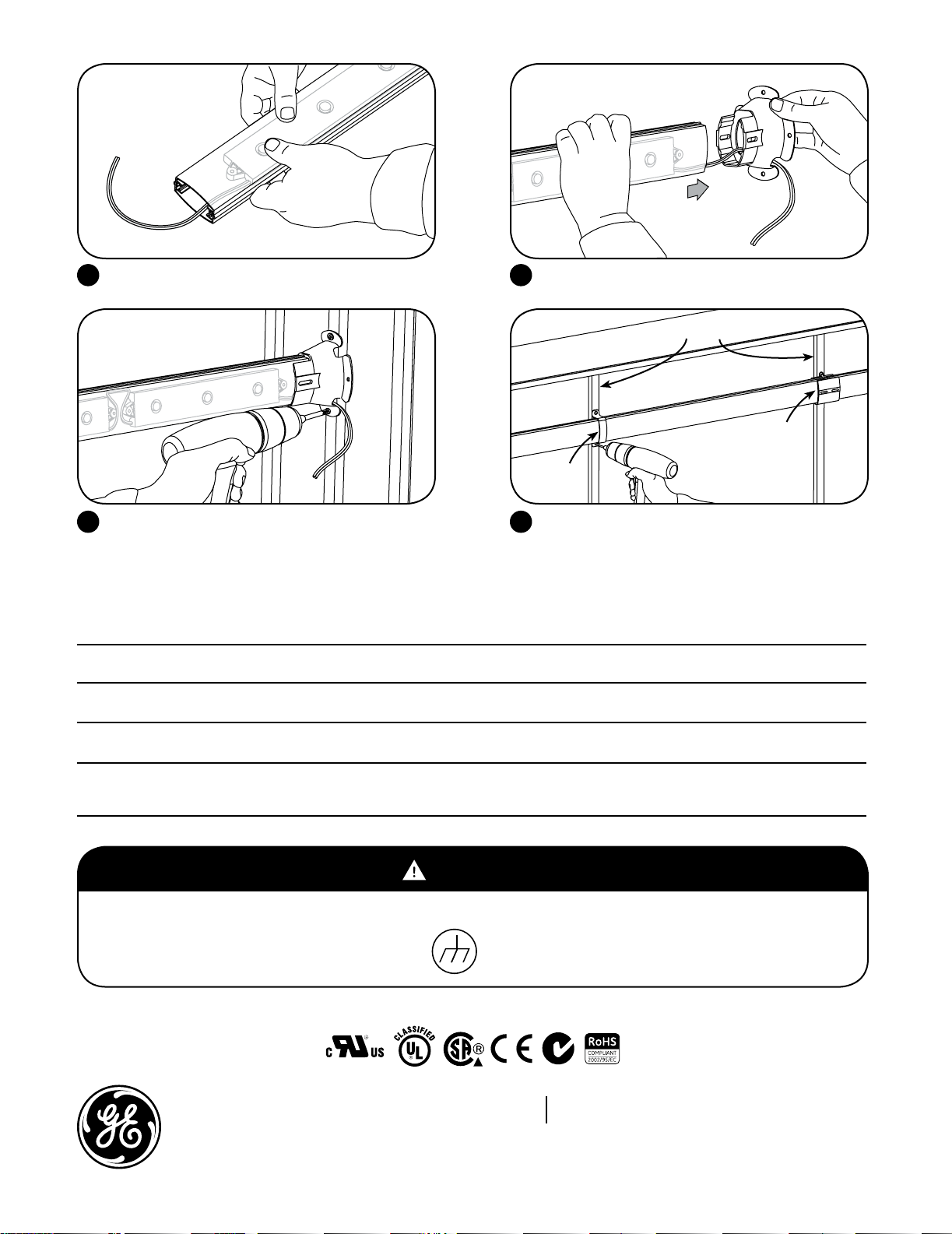

Snap together tube halves. Feed wire through assembly end cap and slide into

assembly end cap.

3 4

Place Tetra PowerStrip Assembly into correct position

and fasten assembly end cap to the sign with two

#6 (M3) screws.

When mounting horizontally assembly supports MUST

BE used to support tubes approximately every 4 ft.

(1.22 m) by mounting assembly supports around tubes

and securing into support stringers with screws.

OPTIONAL: Install a tube connector for longer spans

up to 10 ft. (3.05 m) and push tube ends into connector.

5 6

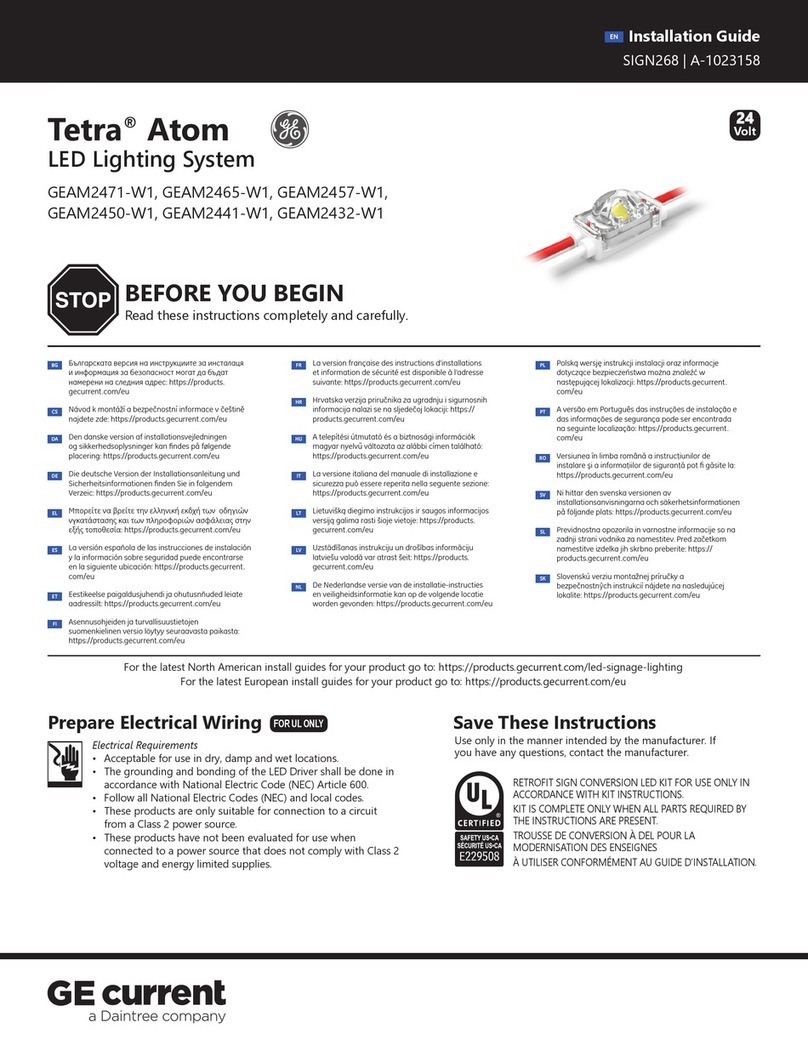

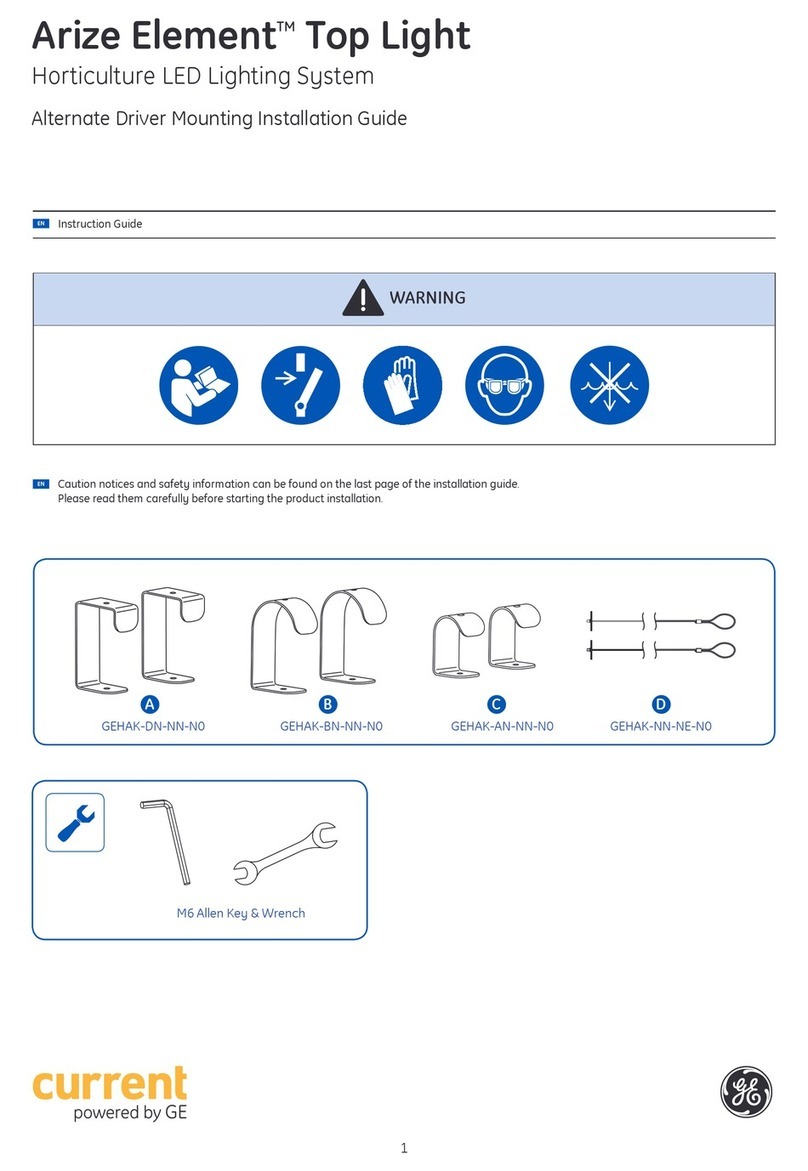

BEFORE YOU BEGIN

Read these instructions completely and carefully.

WARNING/ADVERTISEMENT

Risk of electrical shock. Disconnect power before

servicing or installing product.

Risque de choc électrique. Couper l’alimentation

avant le dépannage ou avant l’installation du produit.

10

10

12 3 4

5

6

7 8 9

Support stringers

Tube

connector

Assembly

support