Section 1- Operating Information

1. Operating Information

This section contains information that will help you prepare for the installation of

the Accelerometer Systems. General information for typical applications,

principles of operation, and monitoring compatibility of the Accelerometers are

presented in this section.

1.1 Application

Accelerometers are very effective when used for the measurement of high

frequency vibrations. Supplemental high frequency casing measurements are

typically required for measuring gear mesh and blade pass frequencies. Section

2explains the proper installation of the Accelerometers.

Application Advisory: If casing acceleration measurements are being

made for the overall protection of a machine, thought should be given to

the usefulness of the measurement for each application. Most common

machine malfunctions, such as unbalance, misalignment, etc., occur on

the rotor and originate as an increase or a change in rotor vibration. For

any casing measurement alone to be effective for overall machine

protection, a significant amount of rotor vibration must be faithfully

transmitted to the machine casing or mounting location of the

transducer. In addition, care should be exercised in the physical

installation of the acceleration transducer on the bearing housing or

machine casing. Improper installation may result in a decrease of the

transducer amplitude and frequency response and the generation of

false signals that do not represent vibration on that particular machine.

1.2 Principle of Operation

The Accelerometer is made up of a piezoelectric shear-mode element and

electronics. When subjected to machinery vibration, this mass/spring system

exerts a force on the piezoelectric ceramic, which generates a charge proportional

to that force. The electronics converts the charge to a voltage that can be sent to

a Bently Nevada monitoring system.

The 330400 and 330425 Accelerometers are designed to monitor vibration

frequencies ranging from 10 Hz to 15 kHz. The calibrated scale factor and

maximum acceleration for the Accelerometers are shown in Table 1.

Table 1-1.

Transducer Scale Factor Maximum

Model (mV/g ± 5%) Acceleration

330400

330425

100 50

25 75

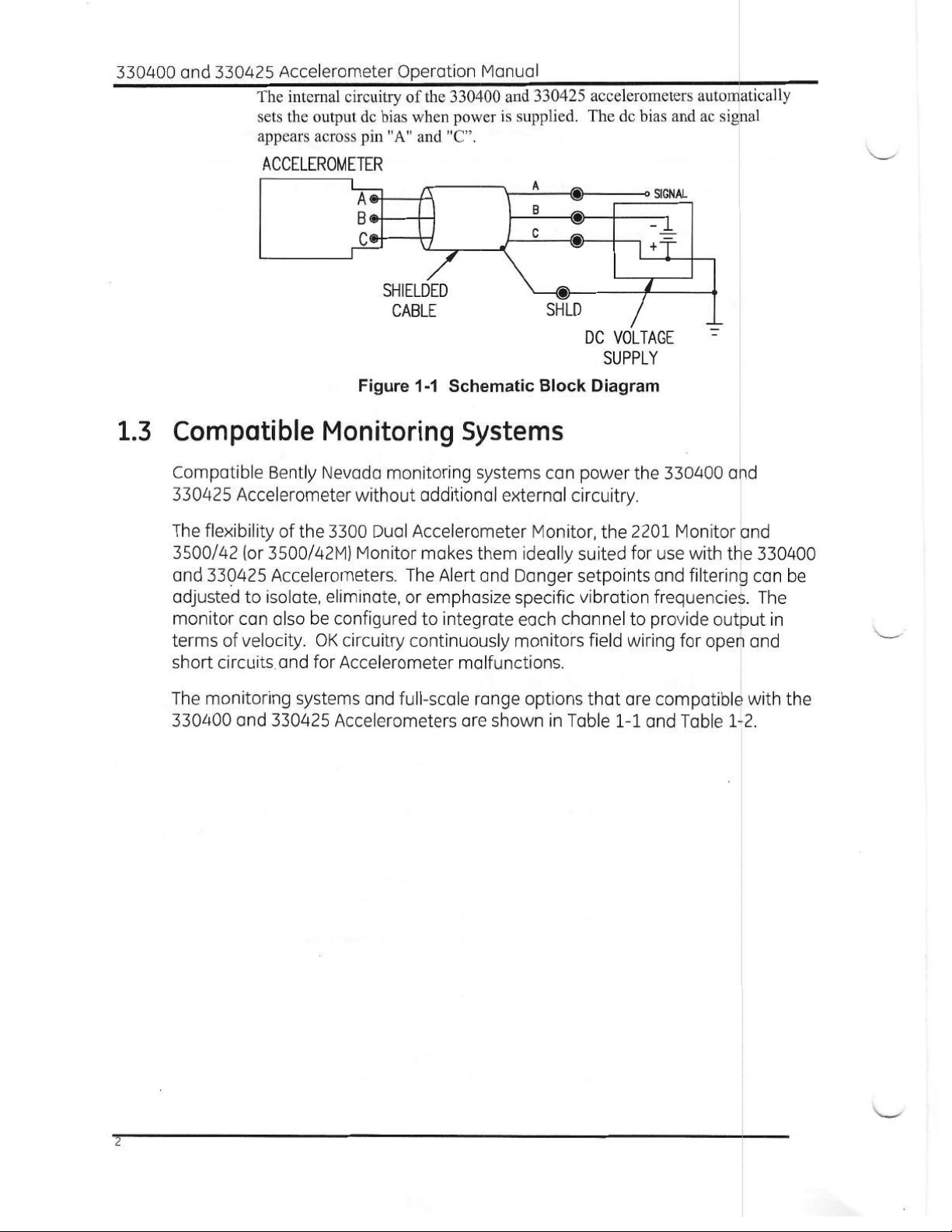

The 330400 and 330425 Accelerometers are three wire transducers which

require external power supplies. The power supply voltage is -24 Vdc. A

simplified schematic block diagram of the 330400 and 330425 Accelerometer

appears in Figure 1-1.

1