CGS990 DOUBLE OVEN -2K5

31-14982-2 07-11

GAS, FREESTANDING, SELF-CLEANING RANGE

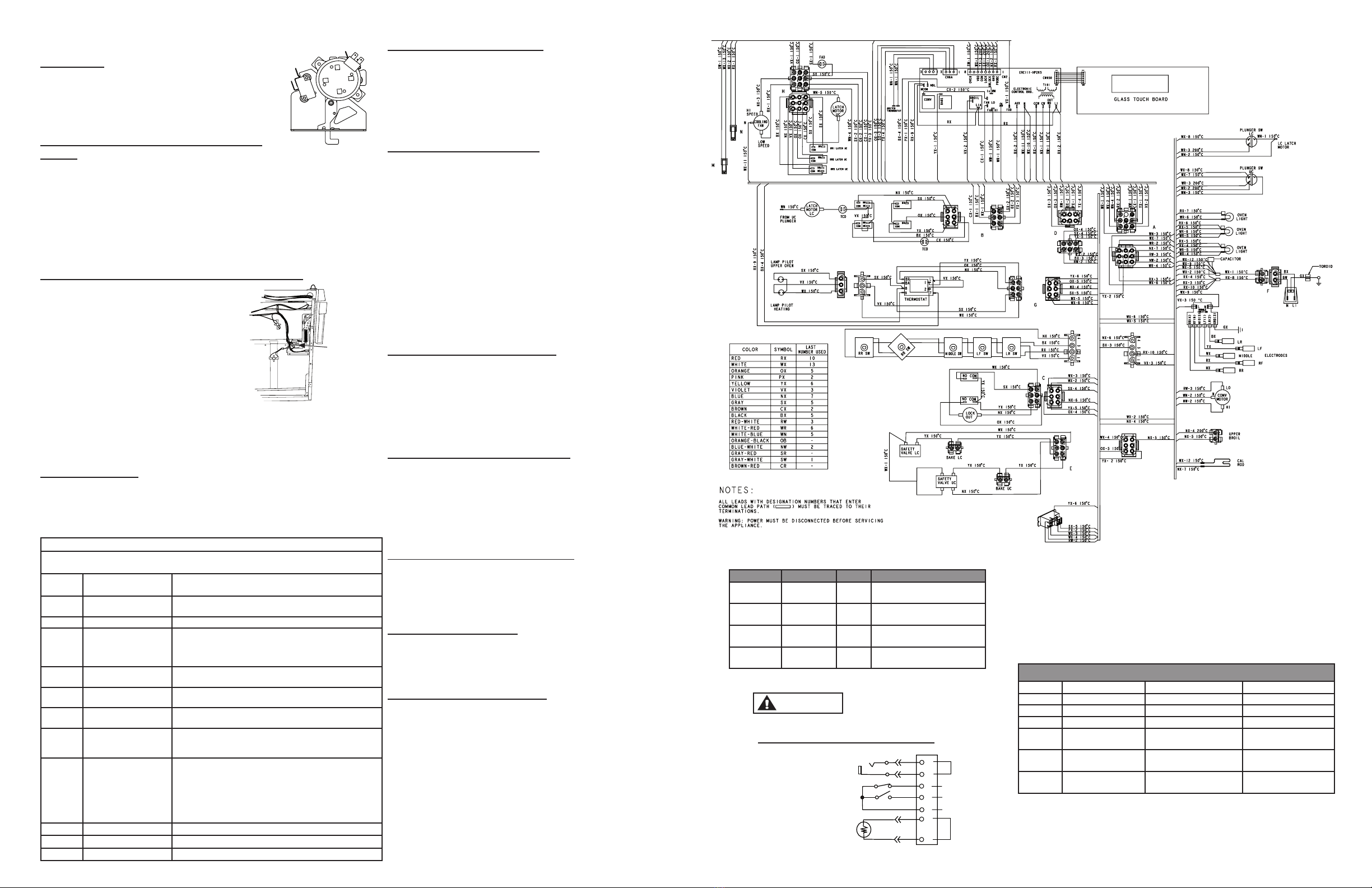

DOOR LATCH

The latch mechanism is thermally operated. When the SELF

CLEAN cycle is selected, the latch will automatically lock for

cleaning and unlock after cleaning. The door locks immediately

and will remain locked until the oven has dropped below these

temperatures (about 420˚F.)

UPPER LOCK MECHANISM AND LOCK SWITCH

ACCESS

1. Remove oven door.

2. Remove the cooktop (see Remove Cooktop in this manual.)

3. Remove manifold panel (remove phillips head screws from burner ame adjustment

switch and 1/4” hex head screws from the underside of the manifold panel.)

4. Remove cover over lock mechanism (remove 1/4” hex head screws on each side of

the cover.)

5. Label and remove wires from lock switch.

6. Remove screws securing lock mechanism to oven frame.

7. Remove mechanism.

Note: After installing mechanism, rotate lock to unlock position to prevent low

temperature lock-up.

LOWER LOCK MECHANISM AND LOCK SWITCH ACCESS

1. If upper door is locked, see Upper Lock Mechanism

and Lock Switch Access to disengage the upper

lock mechanism and remove the upper door.

2. Remove 2 hex screws from front that attach the

lower lock mechanism to the front frame. If lower

door is locked, disengage latch hook to remove

lower oven door.

3. Remove the cooktop (see To Remove Cooktop in

this manual.)

4. Remove manifold panel (remove Phillips

head screw from left and right burner ame

adjustment switch and 1/4” hex head screws

from the underside of the manifold panel.)

5. Remove left side panel (Remove screws at top connecting to burner box. Remove

screws at rear connecting to range back. Remove screw at bottom front connecting to

front frame. Remove screw at top front connecting to side post.)

6.

Lower lock mechanism is located between the upper and lower oven near the front of the unit.

Note: After installing mechanism, rotate lock to unlock position to prevent low

temperature lock-up.

ERC FAILURE CODES

The oven may stop operating but not give an F code on the display immediately. F codes

are stored in nonvolatile eprom memory until the same fault occurs twice consecutively.

After that, the F code will be displayed. F codes can be recalled by pressing together TIMER,

CLOCK, MIN DOWN or 9. While F codes are displayed, pressing MIN UP or 8 and HR, DOWN

or 6 together will clear them.

RELAY CONTACT TO OPERATION TEST

RELAY TERMINALS VOLTAGE IN MODE VOLTAGE IN OFF

BAKE BAKE to N 120 VAC IN BAKE* 0 VAC IN OFF

BROIL BROIL to N 120 VAC IN BROIL** 0 VAC IN OFF

LATCH MDL to N 120 VAC 0 VAC IN OFF

OVEN

LIGHT

LIGHT to L1 120 VAC 0 VAC IN OFF

FAN LO

SPEED

FAN L to N 120 VAC IN CONVECTION

BAKE*

0 VAC IN OFF

FAN HI

SPEED

FAN H to N 120 VAC IN CONVECTION

ROAST*

0 VAC IN OFF

* Be sure to select a temperature or setting

** Must be in Bake cycle. Wait until preheat has completed and call for heat initializes.

FAILURE CODE MEANING & CORRECTIONS

FAILURE CODES WILL BE SHOWN IN THE OVEN CONROL BY PRESSING THE

(TIMER), (8) & (9) KEYS AT THE SAME TIME

FAILURE

CODE MEANING CORRECTION

F0 CLEAR/OFF key input

failure Short for approximately 100 seconds.

F1 Control Failure Loss of element relay redundant driver protection.

F2 Oven temperature

condition due to

sensor input to

control

Oven above 640˚F with Lock input untrue. Oven above

915˚F with Lock input true.

F3 Open Sensor Sensor is 2900 to innite ohms while in a heating

mode.

F4 Shorted Sensor Sensor is 0 to 950 ohms maximum while in a heating

mode.

F6 Failed Gas Valve

Lockout

Open harness switch and/or installed gas lockout

motor.

F7 Shorted key detection

except for slew entry

and Clear/O keys

Short for approximately 40 seconds.

F9 Door lock false

while above

Runaway Setpoint,

Unlatched Door Lock

temperature OR

FAD device setpoint

exceeded.

“Unlock” Latch Changing status to “Lock”. Latch of

Motor changing to “Un-Lock” while above run away set

point.

FC Door Latch error

Unlock home and lock home are try simultaneously.

FD Probe failure

Shorted Probe

FF Control failure

Loss of door motor redundant driver protection.

CIRCUIT TERMINALS OHMS CONDITION

OVEN

SENSOR

6 to 8 1100 OVEN AT ROOM

TEMPERATURE

DOOR

UNLATCHED

3 to 5 0 DOOR LATCH IN BAKE/BROIL

POSITION

DOOR

LATCHED

4 to 5 0 DOOR LATCH IN CLEAN

POSITION

MEAT

PROBE

1 to 2 55000 AT ROOM TEMPERATURE

MEAT PROBE INSERTED

WARNING

Power must be disconnected

before servicing this appliance.

222D6585P010

TO SELF CLEAN IN LOWER OVEN

1. Press SELF CLEAN.

2. Press number pads to enter desired time (4:00 hours is standard).

3. Press START pad.

4. LOr and door will be displayed and LOCKED will be ashing.

CLEAN will be on and

solid indicating the gas valve and doors are locking and the unit is entering self clean.

The gas valve locks rst, then the lower door, then the upper door. The call for heat

will begin once everything has locked successfully. Towards the end of the cycle, the

lower door will unlock, then the upper door, and nally the gas valve. LOCKED will

ash while the doors are unlocking. LOC will ash while the gas valve is unlocking.

TO SELF CLEAN IN UPPER OVEN

1. Turn thermostat to SELF CLEAN position.

2. Press START pad (default time is 5:00 and cannot be changed).

3. UPr and door will be displayed and LOCKED will be ashing.

CLEAN will be on and

solid indicating the gas valve and doors are locking and the unit is entering self clean.

The gas valve locks rst, then the lower door, then the upper door. The call for heat

will begin once everything has locked successfully. Towards the end of the cycle, the

lower door will unlock, then the upper door, and nally the gas valve. LOCKED will

ash while the doors are unlocking. LOC will ash while the gas valve is unlocking.

NOTE FOR SELF CLEAN IN UPPER OR LOWER OVEN: Average clean temperature is

790˚F. Cool down period is 1 hour at the end of the cycle. The self-clean operation

can only be initiated when the range is at room temperature. If any recent oven

cooking has been done, allow the range to cool to room temperature before initiating

a self-clean cycle. If you try to initiate a self-clean cycle in either of the ovens before

the range has reached room temperature, the following will occur: Initially, the

display will look normal. 15 seconds after initiating the cycle, the control will begin

to beep about once every second for approximately 1 minute. After 1 minute, the

beeping will cease and the display will ash the word. LOC. After 15 seconds, the

control will show the time of day, indicating it is now in the standby mode and the

self-clean cycle has been terminated.

OVEN TEMPERATURE CALIBRATION

The bake temperature can be adjusted from its factory calibration (+ or -) 35˚F in 1˚

increments.

1. Press and hold both the BAKE and WARM pads for about 2 seconds until the

display shows SF.

2. Press the BAKE pad. The current oset setting is shown in the display.

3. Enter the desired temperature oset using the number pads.

4. Use the BAKE pad to toggle between +/-.

5. Press START key. The display will return to Time or Day Clock.

BAKE BURNER REMOVAL UPPER OVEN

• Remove oven door and drawer.

• Remove the screws on the oven oor at the back of the oven cavity and remove

oven oor/deector.

• Remove 1/4” hex head screws from the bracket holding the burner to the back

wall of the range.

• Remove the screw at the front of the burner.

• Disconnect the igniter wires.

• Remove the Bake Burner.

BAKE BURNER REMOVAL LOWER OVEN

• Remove oven door and drawer.

• Remove the screws on the oven oor at the back of the oven cavity and remove

oven oor/deector.

• Remove the screw at the front of the burner.

• Disconnect the igniter wires.

• Remove the Bake Burner

BACKGUARD DISASSEMBLY

• Remove screws located on the back of the backguard. (There is a set of screws on

each side.)

• Remove the torx screw on the front inside corner of backguard (1 on each side).

• Gently lift backguard o.

• Be sure to reassemble rear cover and backguard per original assembly.

OVEN BURNER IGNITION SYSTEM

The ignitor is a “Norton” style rectangular glowbar. The ignition circuit consists of

the electronic control, the igniter, and the oven safety valve (gas valve). The three

components are wired in series.

The most important points to know about the ignition system are:

1. THE IGNITOR RESISTANCE DECREASES AS THE IGNITER SURFACE TEMPERATURE

INCREASES.

2. THE SAFETY VALVE OPERATES BY CURRENT, NOT VOLTAGE.

From a cold start, the ignitor needs 30-60 seconds, with voltage applied, to reduce the

electrical resistance enough to provide a minimum of 2.9 amps of current ow in the

series circuit. This is the required current ow needed for the safety valve to open to

supply gas to the burner. The glowbar should provide a steady current ow of between

3.2 to 3.6 amps owing in the circuit. The igniter will remain energized at all times

during burner operation. If the igniter glows red but does not draw at least 2.9 amps,

the fault is usually with the igniter, not the valve. Always check the oven shut-o valve

for a “No Oven” condition.

SENSOR AND LOCK SWITCH CIRCUIT

1

2

3

4

5

6

8

MEAT PROBE CIRCUIT

PINS 1 & 2

UNLOCKED DOOR

LOCKED DOOR

LOCK COMMON

MEAT SENSOR CIRCUIT

PINS 6 & 8

OVEN TEMP SENSOR

1100 OHMS AT ROOM TEMP

2650 OHMS AT CLEAN TEMP

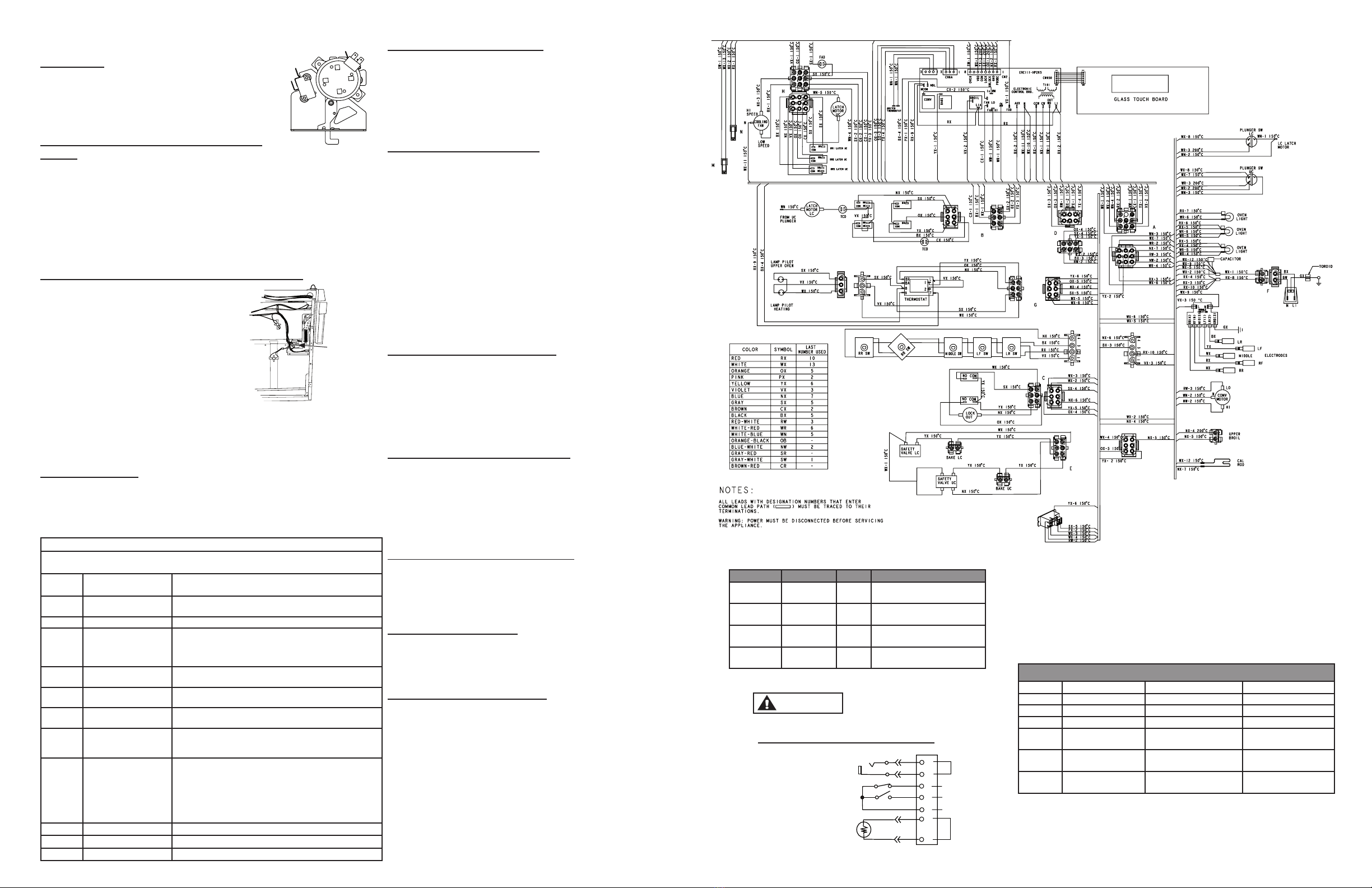

WIRING DIAGRAM

Lower lock

mechanism