2 Safety

2.1.1 High voltage warning

The voltage of the frequency converter is dangerous whenever it is connected to mains. Incorrect installation of the motor or frequency

converter may cause damage to the equipment, serious injury or death. Consequently, it is essential to comply with the instructions in this

manual as well as local and national rules and safety regulations.

2.1.2 Safety instructions

Prior to using functions directly or indirectly influencing personal safety (e.g. Fire Mode or other functions either forcing the motor to stop or

attempting to keep it functioning) a thorough risk analysis and system test must be carried through. The system tests must include testing

failure modes regarding the control signalling (analog and digital signals and serial communication.

• Make sure the frequency converter is properly connected to earth.

• Do not remove mains connections, motor connections or other power connections while the frequency converter is connected to power.

• Protect users against supply voltage.

• Protect the motor against overloading according to national and local regulations.

• The earth leakage current exceeds 3.5 mA.

• The [OFF] key is not a safety switch. It does not disconnect the frequency converter from mains.

2.1.3 General Warning

Warning:

Touching the electrical parts may be fatal - even after the equipment has been disconnected from mains.

Also make sure that other voltage inputs have been disconnected, (linkage of DC intermediate circuit), as well as the motor connection for

kinetic back-up.

Before touching any potentially live parts of the frequency converter, wait at least as follows:

380 - 480 V, 110 - 250 kW, wait at least 20 minutes.

380 - 480 V, 315- 1000 kW, wait at least 40 minutes.

525 - 600 V, 45 - 400 kW, wait at least 20 minutes.

525 - 600 V, 450 - 1000 kW, wait at least 30 minutes.

Shorter time is allowed only if indicated on the nameplate for the specific unit.

Leakage Current

The earth leakage current from the frequency converter exceeds 3.5 mA. According to IEC 61800-5-1 a reinforced Protective Earth connection

must be ensured by means of: a min. 10mm² Cu or 16mm² Al PE-wire or an addtional PE wire - with the same cable cross section as the Mains

wiring - must be terminated separately.

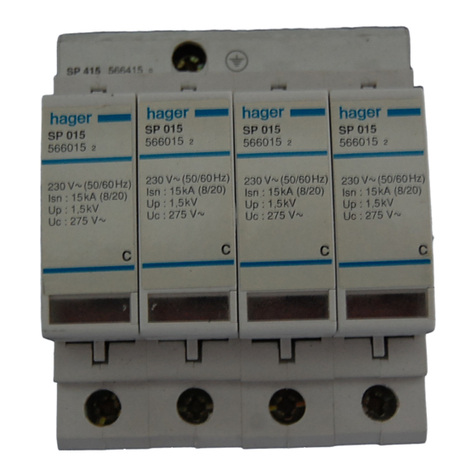

Residual Current Device

This product can cause a D.C. current in the protective conductor. Where a residual current device (RCD) is used for extra protection, only an

RCD of Type B (time delayed) shall be used on the supply side of this product.

Protective earthing of the frequency converter and the use of RCD's must always follow national and local regulations.

AF-600 FP High Power Operating Instructions

7

2