SecoGear 24kV-27kV Air Insulation Switchgear

4

Handling and Storage

Condition on delivery

Packing

Transport

At the time of dispatch, the factory assembled SecoGear will

have withdrawable parts either securely locked in the service

position or packed separately, depending on the rating of the

equipment, transport mode and destination.

The SecoGear panels are verified in the factory for completeness

as per order requirement, and also passed routine testing as per

IEC 62271-200.

The busbars are not assembled, they are packed separately with

fasteners and accessories.

Based on the kind of transportation and country of destination,

the packing may vary. To protect against moisture a drying

agent bag is provided. IEC62271-1:2007 guidelines are followed.

•Panels with basic or no packing

•Panels with seaworthy or similar packing (including packing

for containerized shipments)

o Sealed in polyethylene sheeting

o Transport drying agent bags included

o Moisture indicator included

•Observe the directions for use of the drying agent bags. Note

the following

o Drying agent color observed blue indicates the packaged

equipment is dry condition

o Drying agent color observed pink indicates the packaging

contains moisture (relative humidity above 40%). Please

contact the manufacturer in this case before installation

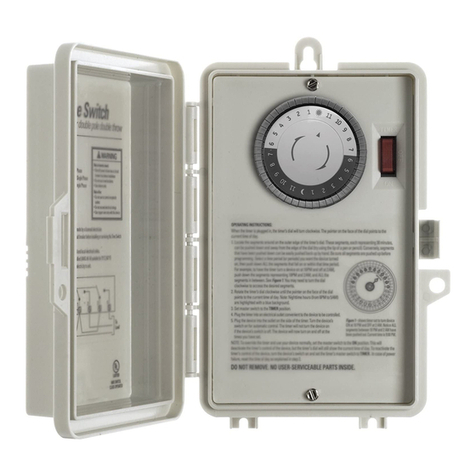

The transport units normally comprise of individual panels and,

in exceptional cases, small groups of panels. The panels are

equipped with four (4) lifting eyebolts.

Only carry out loading operations when all precautionary

measures to protect personnel and materials have been taken,

with the following equipment:

•Crane of suitable capacity; the minimum capacity shall be 2

tonnes

•Fork-lift truck and/or manual trolley

•Lifting ropes/slings of appropriate load capacity with shackles

•Maintain an angle of at least 60°from the front for the ropes

leading to the crane hook (Figure 1/1)

HANG THE UNITS USING ALL 4 EYEBOLTS!

Figure 1/1: Handling by crane

(1) Lifting eyebolts (qty.4)