GuardSwitch™Series 300

371-BT

371-BT

Safety Interlock Switch

Installation

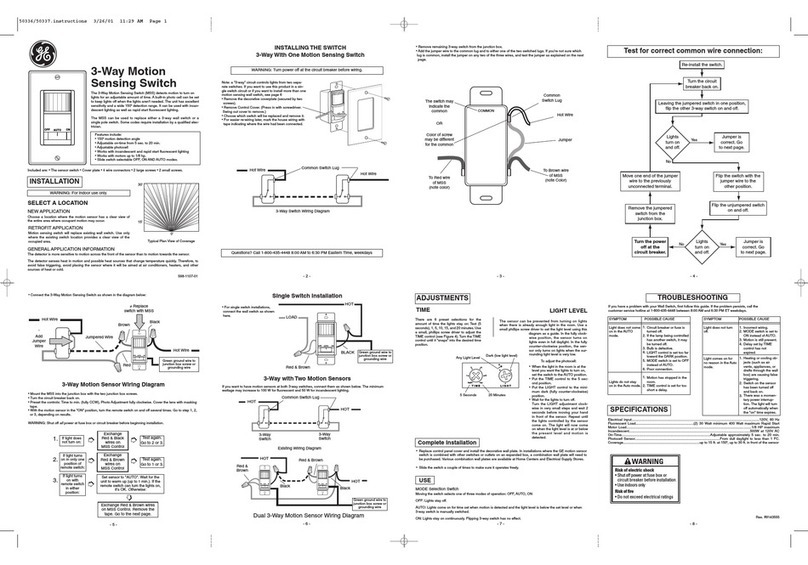

Use non-removable screws, bolts, or nuts to mount the switch and actuator. Do not

over-torque mounting hardware.

1. Position the switch and actuator so the labels are reading in the same direction.

(See Figure 1.)

2. Mount the switch on the stationary frame of the machine and mount the actuator

on the moveable guard, door or gate. Keep the switch and actuator within the

listed sense range. (See Ordering Information.)

See Figure 2 or recommended mounting configurations.

3. Mounting on a ferrous material will effect the sense range a minimum of 50%.

However, a 1/4" non-ferrous spacer positioned under the actuator and/or switch

should restore most of the lost sense range.

4. For best protection against operator defeat, mount with non-removable screws,

bolts or nuts (see Accessories).

5. Caution! When not used with a GE INT safety relay, particular care must be taken to

determine the actual load of the switch circuit. High voltage transients from coils,

motors, contactors, and solenoids must be considered. Transient protection, such

as back-to-back zener diodes (TransZorb®) or an RC network, is recommended for

such loads to ensure that maximum ratings of the switch are not exceeded. Not

recommended to be used with tungsten filament loads because of high current

inrush surges. Line capacitance and load capacitance must be considered.

Excessive line capacitance can be caused by cable lengths over 50' when using a

maximum 48 VAC. A resistor can be added in series to limit the inrush current (at

least 48 Ohms for 24V applications). The resistor can be added in series just before

the load. The voltage drop and the power rating of the resistor must be considered.

Voltage drop = I•R; Watts = I2R (I = maximum continuous current of the load).

continued

Description

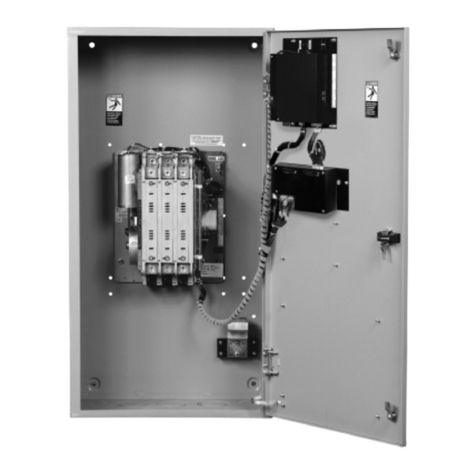

The 371-BT Series DPST safety interlock switch is designed for use with safety

monitored relays or monitored circuits. To achieve the optimum Series 300 defeat

resistant feature of the 371-BT, both the switch circuit (Circuit 1) and the tamper

circuit (Circuit 2) must be connected.

Notes:

1. Environmental: Pollution Degree II

2. Correct use of this control device is an essential part of proper machine cycle

control.

3. Failure to follow ALL instructions could lead to serious bodily injury or death.

4. Maintenance to be done by qualified personnel only

5. The connecting cables between the INT devices and the switches must be located

in an IP 23 type enclosure (minmum).

6. The mounting for the switch and the actuator magnet must be accomplished per

this specification.

7. Non-removable hardware must be used for installation.

8. The housing of the 300-BT must be connected to the PE (Primary Earth) ground

circuit via a lock washer on the mounting screw. The PE ground symbol must be

placed adjacent to the screw.

To verify switch operation with an ohmmeter:

Set range at 20 mega ohms (switches with triac output, set ohm range at 20 kilo

ohms). For a normally open switch, the meter will read a high impedance with the

actuator away. It will read very high to infinity range (triac switches will read high

kilo ohm to infinity range) with the actuator within sense range. You will see the

opposite reading for a normally closed switch.

Dimensions

5.75''

14.61cm

5.27''

13.39cm

0.24''

0.61cm

0.83''

2.11cm 0.42''

1.07cm 5.75''

14.61cm

5.26''

13.36cm

0.24''

0.61cm

0.64''

1.63cm

2.03''

5.16cm

0.64''

1.63cm

2.33''

5.92cm

1.10''

2.79cm

0.28''

0.71cm

1.12''

2.84cm

1.49''

3.78cm

0.22''

0.56cm

dia.

1.51''

3.84cm

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email:

[email protected]