Before you begin - Read these instructions completely and careflllly.

IMPORTANT - Save these instructions for local inspector's use.

IMPORTANT - OBSERVE AI,L GOVERNING (;ODES AND ORDINANCES.

Note to Installer - Be sure to leave these instructions with the Consumer.

Note to Consumer - Keep these instructions with your Owner's Manual for flmne reference.

WARNING: This appliance must be properly grounded. See "Electrical Supply," page 5.

If you have a question concerning the

installation of this product, call the GE Answer

Center ®Consumer Information Service at

800.626.2000, 24 hours a day, 7 days a week.

If you received a damaged vent hood, you

should immediately contact your dealer or

builder.

For Monogram local service in your area,

1.800.444.1845.

For Monogram service in Canada, call

1.888.880.3030.

For Monogram Parts and Accessories, call

1.800.626.2002.

(;cAUTION!

Due to the weight and size of this vent hood

and to reduce the risk of personal i_jury or

damage to the product, TWO PEOPI,E ARE

REO,.UIRED FOR PROPER INSTAI,I,ATION.

Proper installation is the responsibility of

the installer. Product failure due to improper

installation is not covered under the GE

Appliance _¥arranty. See the Owner's

Manual for warranty information.

_i_SkRNING:

To reduce the risk of fire or elecuical

shock, do not use this hood with any external

solid-state speed conuol device. Any such

alteration flom original factory wiring could

result in damage to the unit and/or create

an elecuical safety hazard.

To reduce the risk of fire and to properly

exhaust air, be sure to duct air outdoors. Do

not vent exhaust air into spaces within walls or

ceilings or into attics, crawl spaces or garages.

_i_SkRNING: TO REDUCE THE RISK OF FIRE,

USE ONIX METAl, DUCTWORK

TO REDUCE THE RISK OF FIRE,

EI,ECTRICAI, SHOCK OR INJURY TO

PERSONS, OBSERVE THE FOI,I,OWING:

A. Use this unit only in the manner intended

by the manufactureL If you have any

questions, contact the manufacturer.

B. Before servicing or cleaning unit, switch

power off at the service panel and lock service

panel to prevent power flom being switched

on accidentally. If the service panel cannot be

locked, fasten a tag or prominent warning

label to the panel.

For general ventilating use only. Do not use

to exhaust hazardous or explosive materials

or vapors.

Structural flaming, installation work and

elecuical wiring must be done by qualified

person (s), in accordance with all applicable

codes and standards including fire-rated

construction.

Sufficient air is needed for proper combustion

and exhausting of gases through the flue

(chimney) of tirol burning equipment to

prevent back drafting. Follow the heating

equipment manufacturer's guidelines and

safety standards such as those published by

the National Fire Protection Association

(NFPA), and the American Society for

Heating, Refligerafion and Air Conditioning

Engineers (ASHRAE), and the local code

authorities.

I,ocal codes vary. Installation elecuical

connections and grounding must comply

with applicable codes. In the absence of

local codes, the vent should be installed in

accordance with National Electrical (;ode

ANSI/NFPA 70-1990 or latest edition.

Contents Model Available ............................................ 3

Required Accessory ...................................... 3

Recirculating Operation .............................. 3

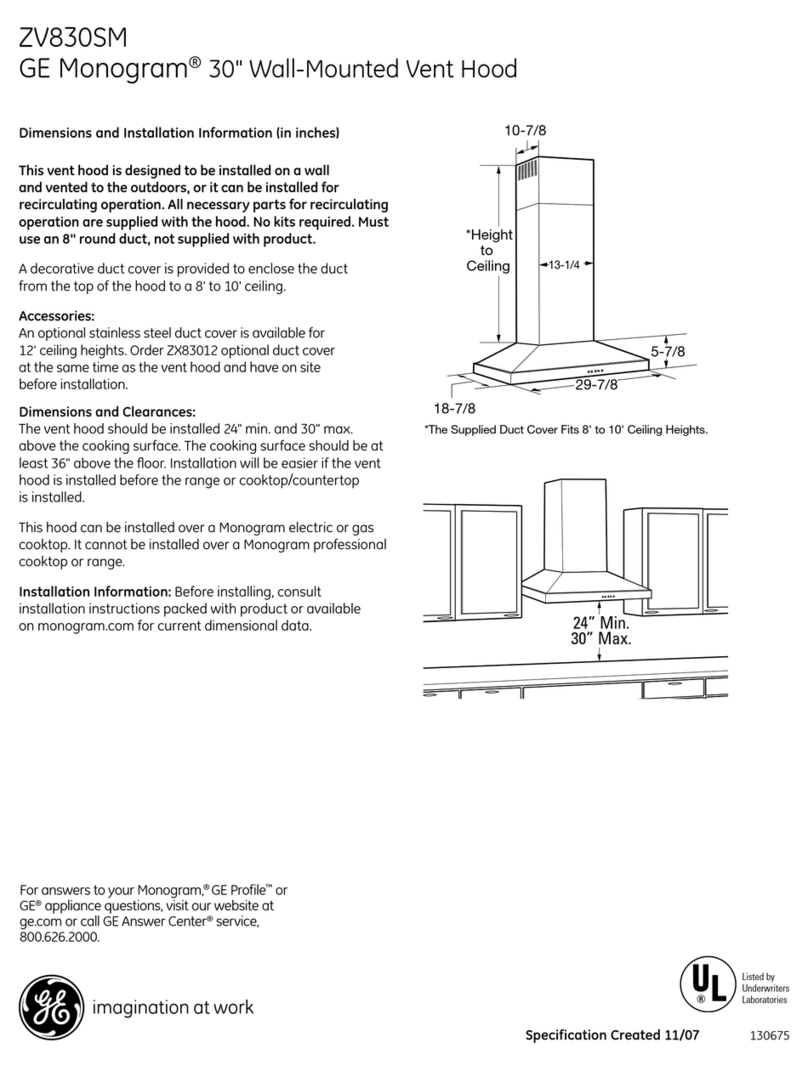

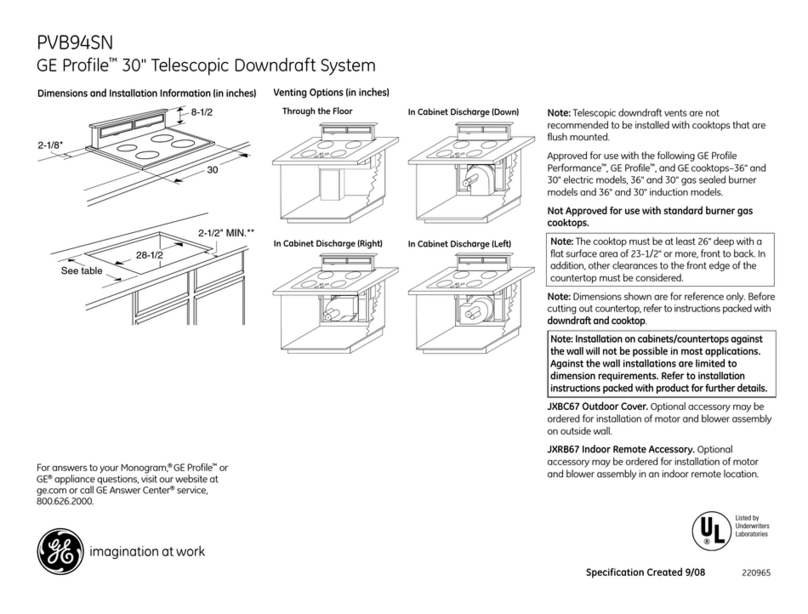

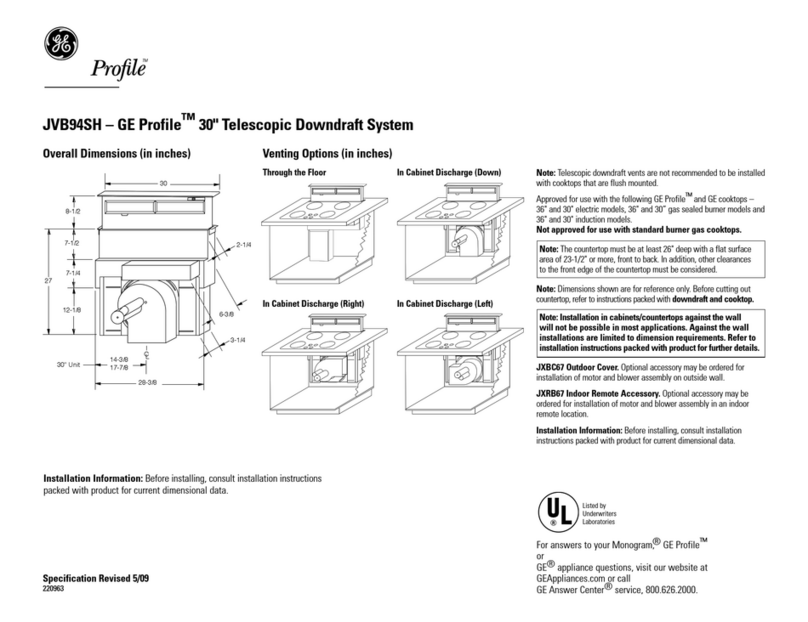

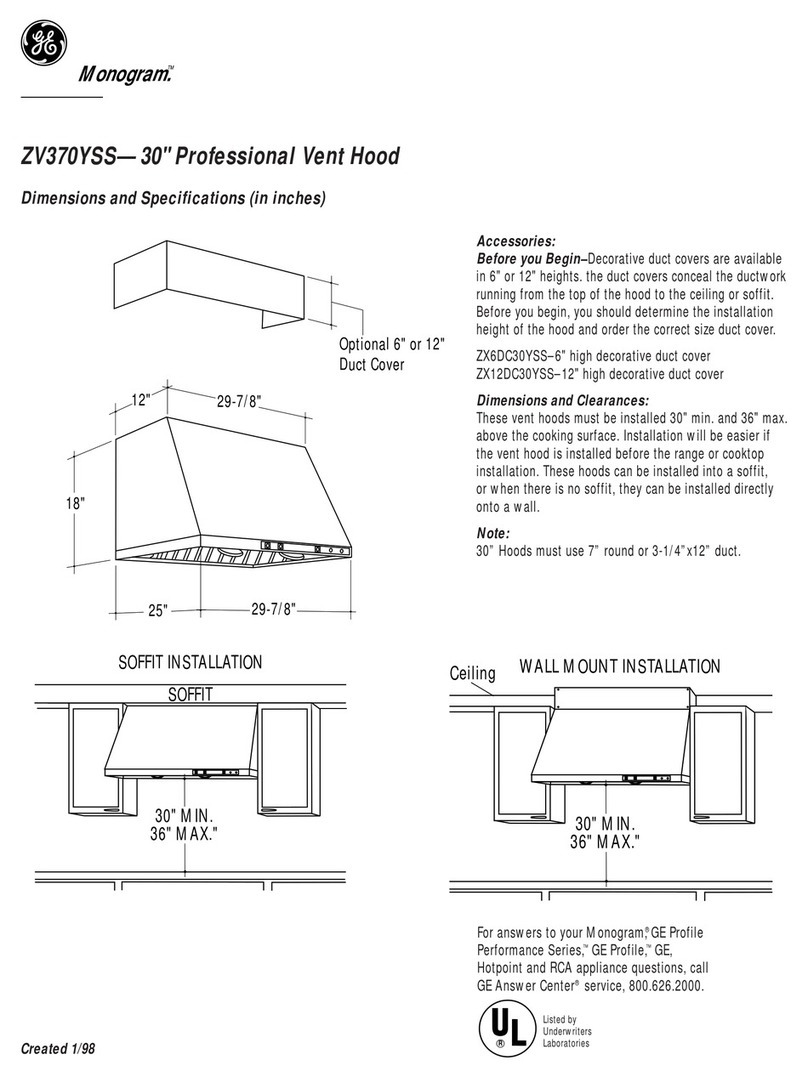

Product Dimensions ..................................... 3

Using Duct Cover Accessories ..................... 4

Installation Preparation

Tools and Materials Required ..................... 5

Power Supply ................................................ 5

Duct Fittings ................................................. 6

Step 1, Advance Planning ........................ 7, 8

Installation

Step 2, Remove the Packaging .................... 9

Step 3, Check Installation Hardware .......... 9

Step 4, Mount Template ............................ 10

Step 5, Install Support Frame .................... 10

Step 6, Secure Wiring ................................ 11

Step 7, Size and Install Ductwork .............. 11

Step 8, Install Decorative Duct Covers ..... 12

Step 9, Install Hood ................................... 13

Step 10, Connect Electrical ....................... 13

Step 11, Slide Duct Cover Down,

Install Side Utility Bars ................ 14

Step 12, Install Filters ................................. 15

Step 1,3,Finalize Installation ..................... 15