8

D

GB

F

E

I

Ru

09971-06.2016-DGbFEIRu

INFO For refilling, we recommend the above oil types.

Alternatives: see lubricants table, Chapter 7.5

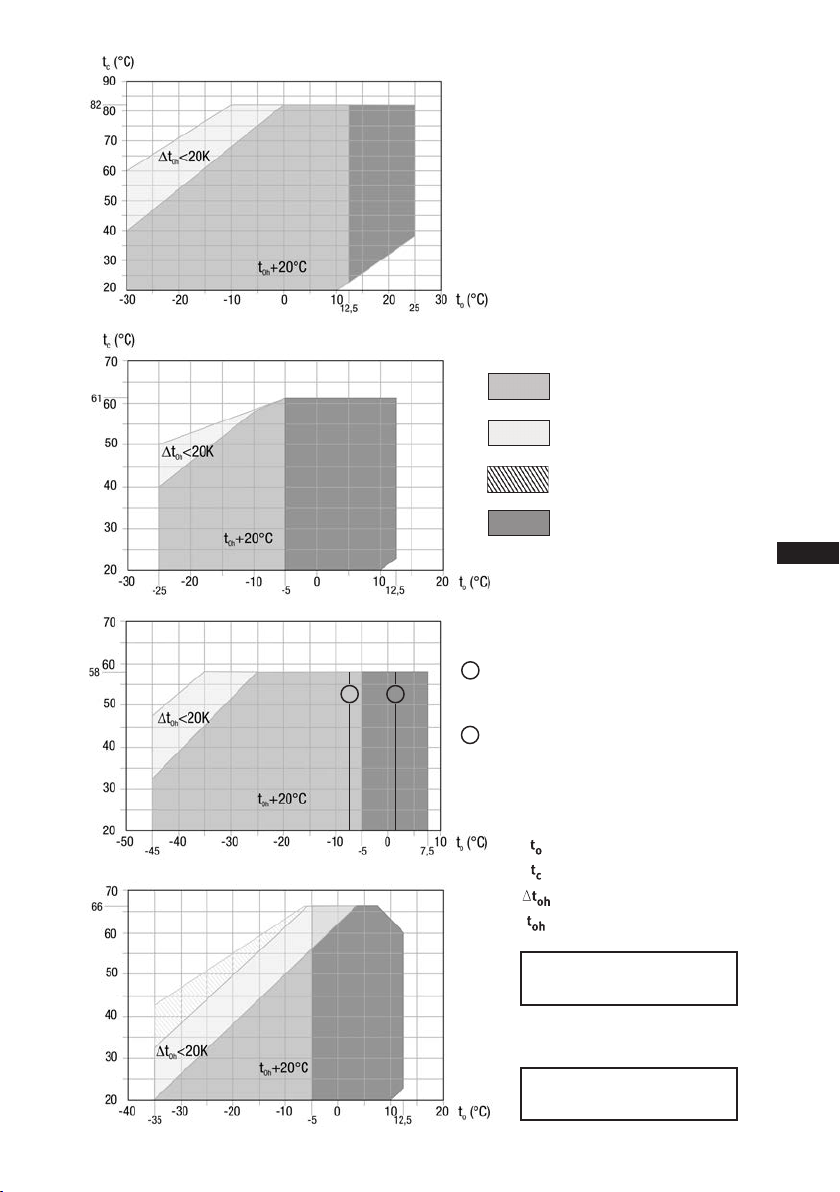

ATTENTION Compressor operation is possible within the operating limits

showninthediagrams.Pleasenotethesignicance

of the shaded areas. Thresholds should not be selected as

design or continuous operation points.

- Permissible ambient temperature (-20°C) - (+60°C)

- Max. permissible discharge end temperature 140°C.

-Max.permissibleswitchingfrequency12x/h.

- A minimum running time of 3 min. steady-state condition

(continuous operation) must be achieved.

For operation with supplementary cooling:

- Use only oils with high thermal stability.

- Avoid continuous operation near the threshold.

For operation with capacity regulator:

- Continuous operation, when the capacity regulator is activated,

is not permissible and can cause damage to the compressor.

- The suction gas superheat temperature may need to be reduced

or set individually when operating near to the threshold.

- When the capacity regulator is activated, the gas velocity in the

systemcannotundercertaincircumstancesensurethatsuf-

cient oil is transported back to the compressor.

Foroperationwithfrequencyconverter:

- The maximum current and power consumption must not be

exceeded.Inthecaseofoperationabovethemainsfrequency,the

application limit can therefore be limited.

When operating in the vacuum range, there is a danger of air

entering on the suction side. This can cause chemical reactions,

a pressure rise in the condenser and an elevated compressed-gas

temperature. Prevent the ingress of air at all costs!

3.3 Limits of application

3|Areas of application

Thecompressorsarelledatthefactorywiththefollowingoiltype:

- for R134a, R404A/R507, R407C FUCHS Reniso Triton SE 55

- for R22 FUCHS Reniso SP 46

Compressors with ester oil charge (FUCHS Reniso Triton SE 55) are marked with an X in the type

designation (e.g. HGX6/1410-4).

3.1 Refrigerants

• HFKW / HFC: R134a, R404A/R507, R407C

• (H)FCKW / (H)CFC: R22

3.2 Oil charge

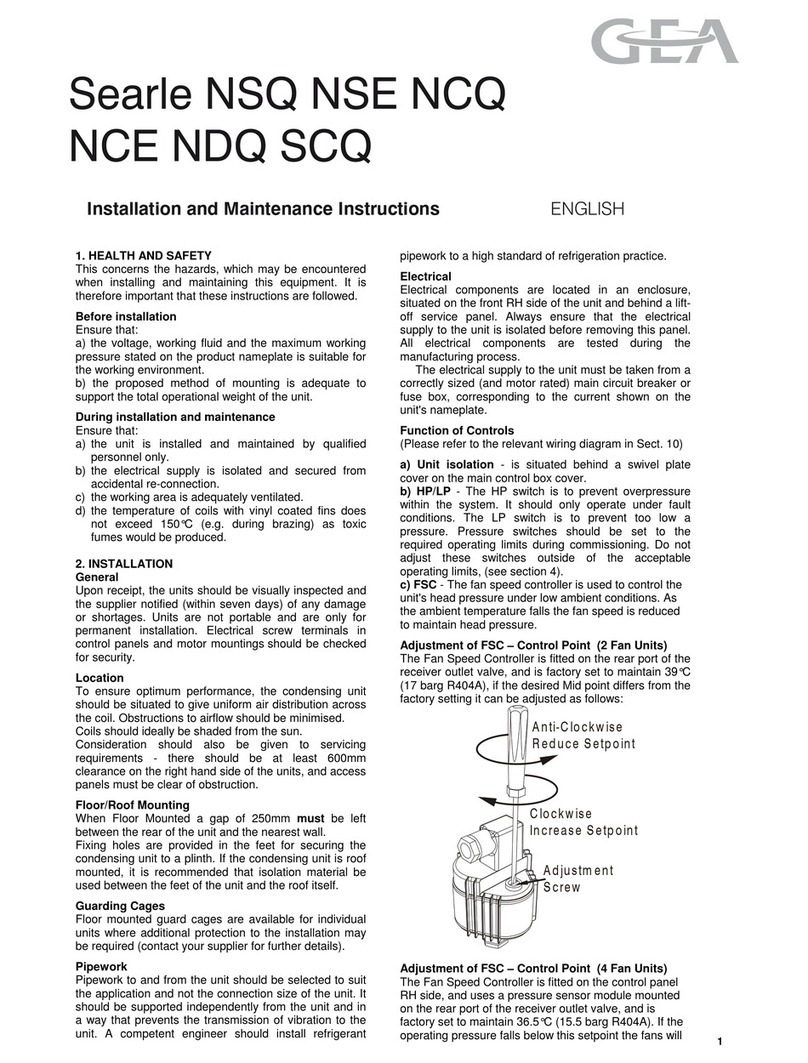

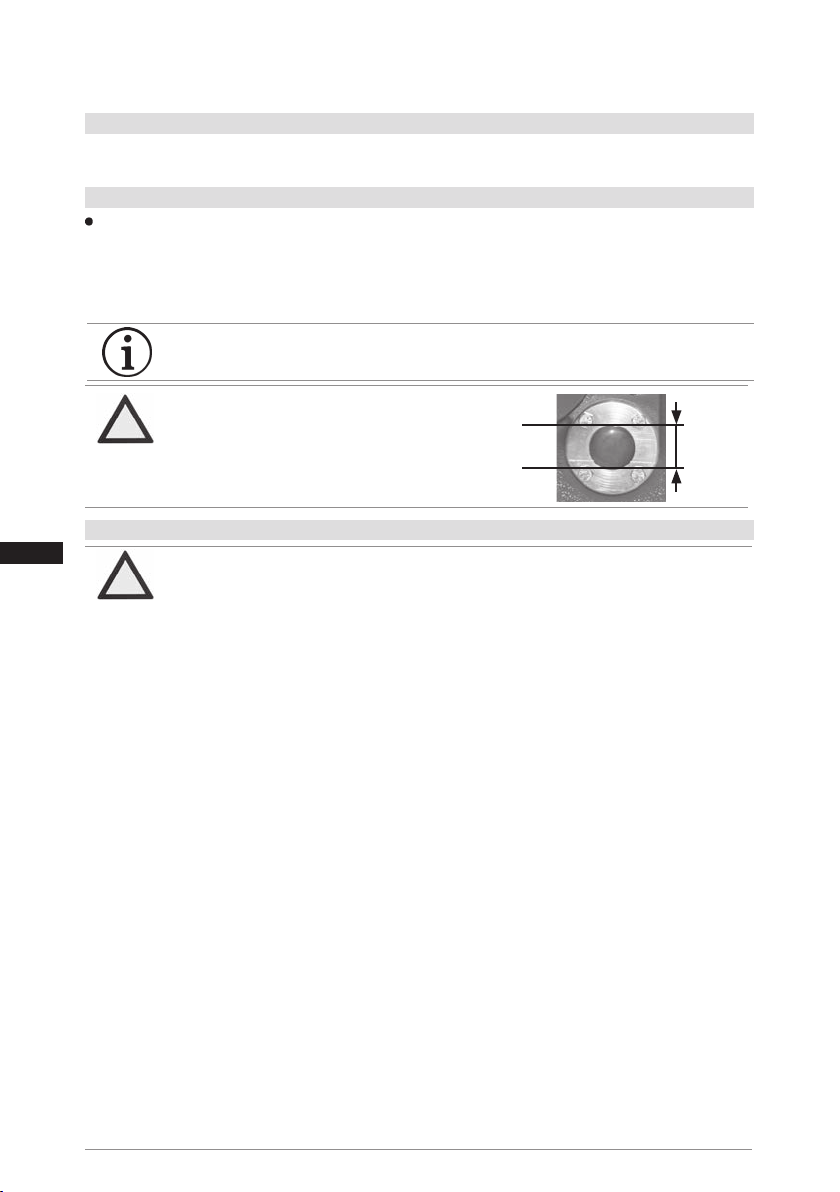

Fig. 4

max.

min.

2,0 Ltr.

oil level ~

~

ATTENTION The oil level must be in the

visible part of the sight glass;

damage to the compressor is

possible if overfilled or under-

filled!