10

D

GB

F

E

96416-08.2020-DGbFEIRu

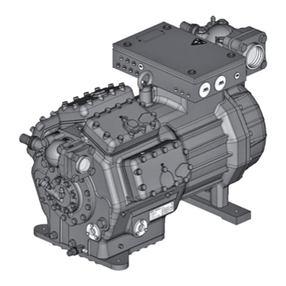

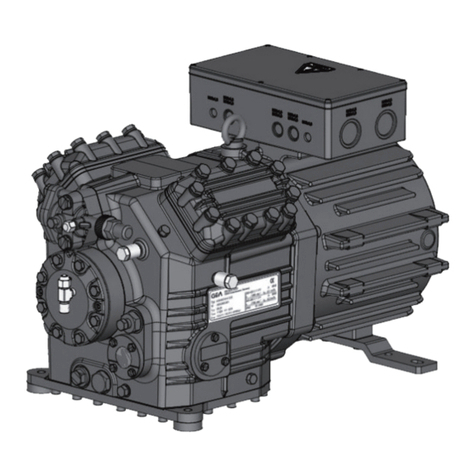

ATTENTION The oil level must be in the

visiblepartofthesightglass;

damage to the compressor

is possible if overfilled or

underfilled!

4 |Areas of application

Thecompressorsarelledatthefactorywiththefollowingoiltype:

-fürR134a,R404A/R507,R407C,R407F FUCHSRenisoTritonSE55

-fürR22 FUCHSRenisoSP46

Compressorswithesteroilcharge(FUCHSRenisoTritonSE55)aremarkedwithanXinthetype

designation(e.g.HGX44e/770-4).

4.1 Refrigerants

• HFKW/HFC: R134a,R404A/R507,R407C,R407F

• (H)FCKW/(H)CFC: R22

4.2 Oilcharge

INFO Forrefilling,werecommendtheaboveoiltypes.

Alternatives:seelubricantstable,Chapter 7.5

ATTENTION Compressoroperationispossiblewithintheoperatinglimits.

ThesecanbefoundinBockcompressorselectiontool(VAP)

undervap.bock.de.Observetheinformationgiventhere.

-Permissibleambienttemperature(-20°C)-(+60°C)

-Max.permissibledischargeendtemperature140°C.

-Max.permissibleswitchingfrequency12x/h.

-Aminimumrunningtimeof3min.steady-statecondition

(continuousoperation)mustbeachieved.

Foroperationwithsupplementarycooling:

-Useonlyoilswithhighthermalstability.

-Avoidcontinuousoperationnearthethreshold.

Foroperationwithcapacityregulator:

- Continuousoperation,whenthecapacityregulatorisactivated,

isnotpermissibleandcancausedamagetothecompressor.

-Thesuctiongassuperheattemperaturemayneedtobereduced

orsetindividuallywhenoperatingneartothethreshold.

- Whenthecapacityregulatorisactivated,thegasvelocityinthe

systemcannotundercertaincircumstancesensurethatsuf-

cientoilistransportedbacktothecompressor.

Foroperationwithfrequencyconverter:

- The maximum current and power consumption must not be

exceeded.Inthecaseofoperationabovethemainsfrequency,the

applicationlimitcanthereforebelimited.

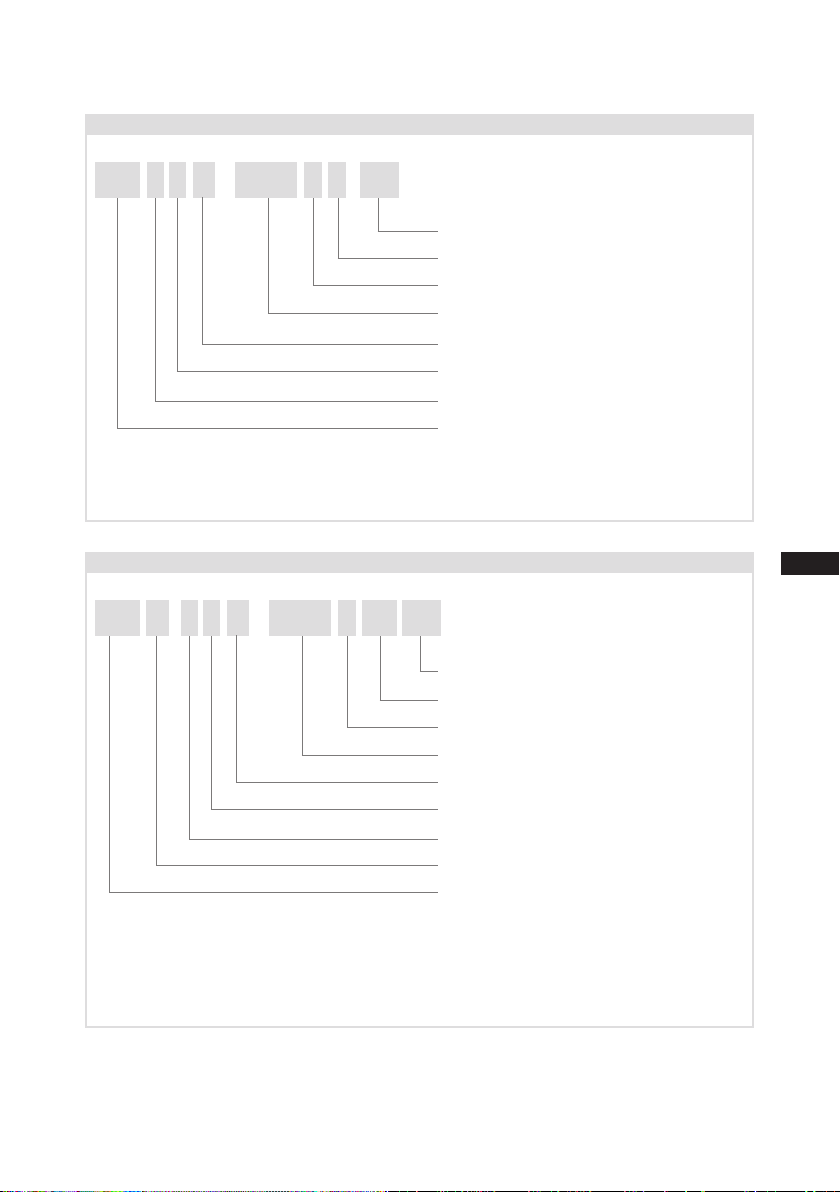

4.3 Limitsofapplication

max.

min.

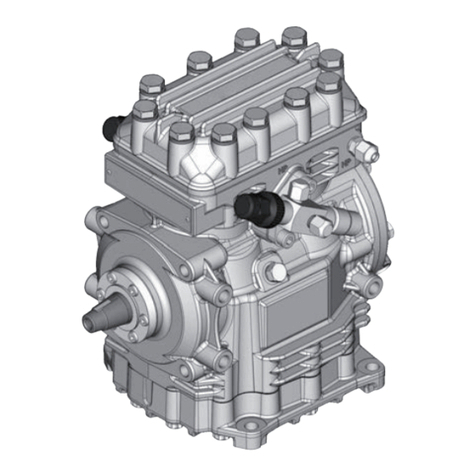

oillevel

Fig.4Fig.4Fig.4

HG44e

1,6Ltr.

HG56e

1,4Ltr.

~

~

~

~