TABLE OF CONTENTS

SECTION DESCRIPTION

PAGE

Introduction ............................................................... 1

1 SAFETY .......................................................................... 2 - 11

1.1 Safety Warnings ...................................................... 3 - 4

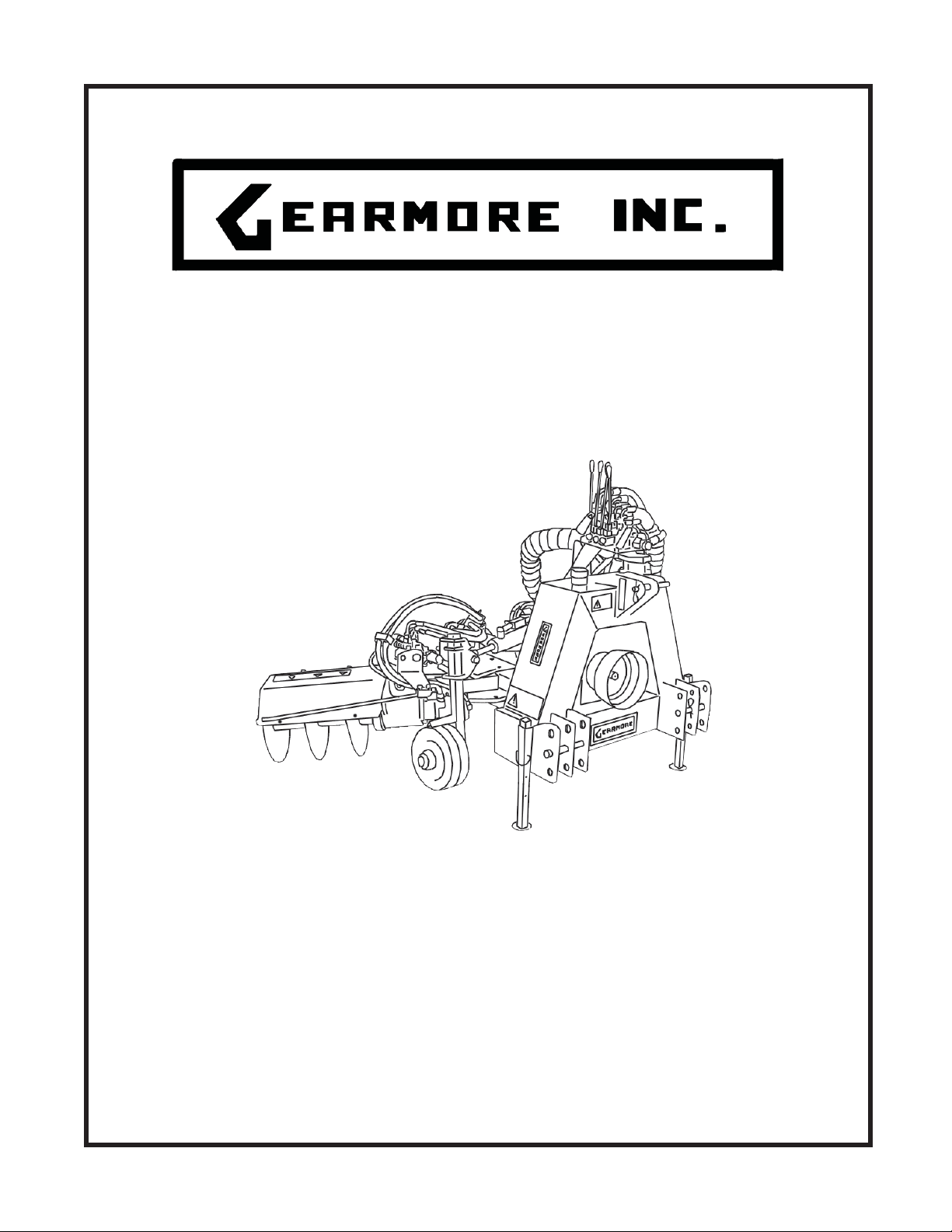

1.2 Description .................................................................... 5

1.3 Machine Identification.................................................. 6

1.4 Safety Labels................................................................. 7

1.4.1 Driveshaft Safety Labels......................................... 8

1.5 General Safety Rules ............................................. 9 - 10

1.5.1 Driveshaft General Safety Rules .......................... 11

2 TECHNICAL INFORMATION................................................... 12 - 14

2.1 Technical Specifications ............................................. 12

2.2 Hydraulic Sys. Single Pump Liquid........................... 12

2.3 Hydraulic Sys. Single Pump Electric......................... 13

2.4 Hydraulic Sys. Double Pump Electric ....................... 14

3 PACKAGING ................................................................................ 15

3.1 Unpacking ................................................................... 15

3.2 Package Disposal ........................................................ 15

4 TRANSPORT ......................................................................... 16 - 17

4.1 Handling & Transporting........................................... 16

4.2 Handling & Transport Warnings............................... 17

5 SAFETY ................................................................................ 18

5.1 Safety Rules ................................................................ 18

6 SET-UP ......................................................................... 19 - 29

6.1 Start Up....................................................................... 19

6.2 Equipment Installation ....................................... 19 - 20

6.3 Manual /Electric Control Installation ....................... 20

6.3.1 Manual Control Unit Functions............................ 21

6.3.2 Electric Control Board Functions ......................... 22

6.4 PTO Driveline Installation......................................... 23

6.5 PTO Rotation Speed ................................................... 24

6.6 Start-Up ...................................................................... 24

6.7 Installation of Power Disc .......................................... 25

6.8 Sensing Device Rod Adjustment ................................ 26

6.8.1 Advance Device Adjustment ................................. 26

6.8.2 Horizontal Adjustment.......................................... 27

6.9 Vertical Adjustment ................................................... 28

6.10 Lateral Adjustment .................................................... 28

6.11 Head Unit Raising ............................................... 28 - 29

6.12 Installation of Back Fill Disc ..................................... 29

7 OPERATION ......................................................................... 30 - 33

7.1 Working ....................................................................... 30

7.2 Power Discing ............................................................. 30

7.3 Sensing Device Sensitivity Adjustment .................... 31

7.4 Back Fill Disc .............................................................. 32

7.5 Safety Instructions ..................................................... 33