2.6 OPERATING SAFETY

7

Please remember it is important that you read and

heed the safety signs on the tractor and disc. Clean

or replace all safety signs if they cannot be clearly

read and understood. They are there for your safety,

as well as the safety of others. The safe use of this

machine is strictly up to you, the operator.

All things with moving parts are potentially haz-

ardous. There is no substitute for a cautious, safe-

minded operator who recognizes potential hazards

and follows reasonable safety practices. The manu-

facturer has designed these Discs to be used with all

its safety equipment properly attached to minimize

the chance of accidents. Study this manual to make

sure you have all safety equipment attached.

Practice raising and lowering the disc when learning

to operate the Tandem disc. Become familiar with

controls before operating.

If a safety shield or guard is removed for any rea-

son, it must be replaced before the machine is again

operated.

Always operate disc with hitch hydraulic control

lever in lowered "float" position.

Do not operate near the edge of drop-offs or banks.

Do not operate at an angle on steep slopes. Drive

up or down but not across. Always lift disc before

turning at ends of field.

Make allowances for increased length and weight of

tractor during operation and moving.

Remove all sticks, stones, roots and wires from work-

ing area before starting. Take care not to contact

overhead obstructions during operation.

Never operate controls from the ground. Operate

only from the operators seat to prevent unexpected

movement that can lead to crushing between frame

members.

Start operation at a slower comfortable speed; in-

crease tractor speed as clods reduce size.

Keep disc away from overhead power lines. Elec-

trocution can occur without direct contact with an

overhead power line.

Never carry, lift or move people on disc. Do not use

machine as a work platform.

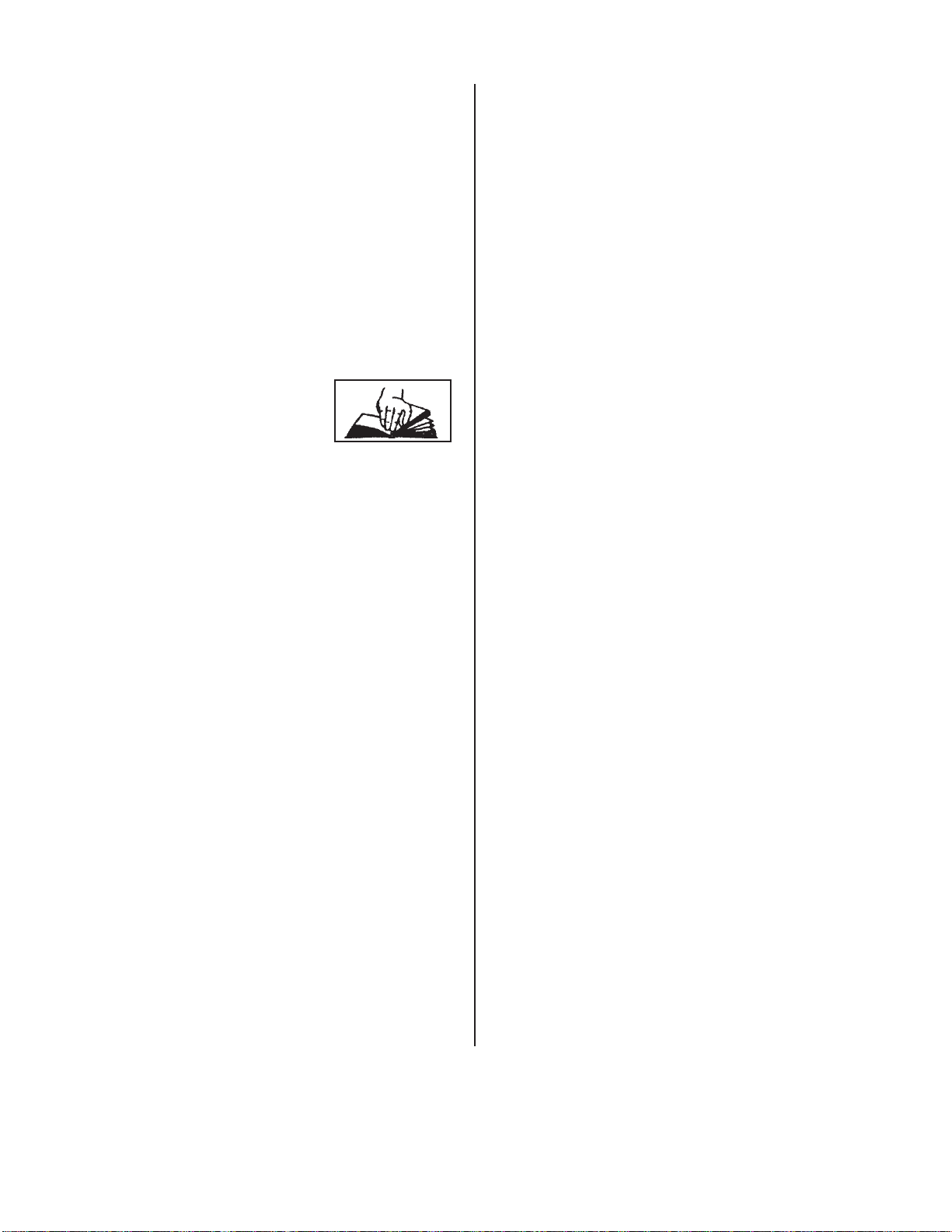

Always use two people to handle heavy, unwieldy

components during assembly, installation, removal

or moving.

Never place any part of your body where it would be

in danger if movement should occur during assem-

bly, installation, operation, maintaining, repairing,

removal or moving.

Do not walk or work under a raised machine or at-

tachment unless it is securely blocked or held in posi-

tion. Do not depend on the tractor hydraulic system

to hold the machine or attachment in place.

Never use alcoholic beverages or drugs, which can

hinder alertness or coordination, while operating

this equipment. Consult your doctor about operat-

ing this machine while taking prescription medica-

tions.

Do not allow riders on the machine or tractor at any

time. There is no safe place for any riders.

Do not go under raised disc. Keep others away.

Add sufficient amount of weight to front end of trac-

tor to prevent wheels from coming off the ground

when starting suddenly with a load.

Always remove the key when leaving the tractor

unattended.

Never allow disc to be left in the "up" position when

unattended.

Before you operate the machine, check over all pins,

bolts and connections to be sure all are securely in

place. Replace any damaged or worn parts imme-

diately.

Review safety instructions annually.