215593 vi Revision A

3.11.5 Running up the Conditioner ......................................................................................................... 50

3.11.6 Storing Manuals......................................................................................................................... 50

Chapter 4: Operation................................................................................................................................ 51

4.1 Owner/Operator Responsibilities ............................................................................................................ 51

4.2 Operational Safety................................................................................................................................ 52

4.2.1 Shutting down the Machine ........................................................................................................... 52

4.3 Attaching Hay Conditioner to Header ....................................................................................................... 53

4.4 Detaching Hay Conditioner from Header .................................................................................................. 54

4.4.1 Detaching Hay Conditioner –Windrower Method.............................................................................. 54

4.4.2 Detaching Hay Conditioner –Lifting Method..................................................................................... 58

4.5 Detaching Feed Draper Deck and Rock Grate............................................................................................. 62

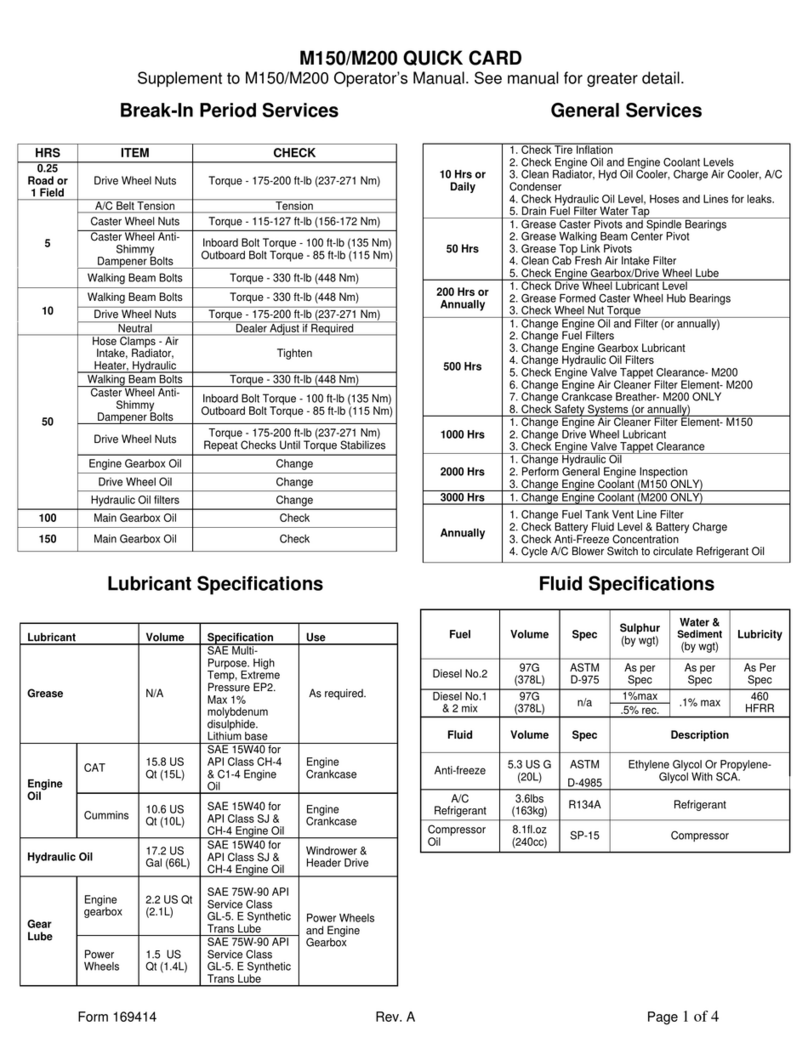

4.6 Break-in Period .................................................................................................................................... 65

4.7 Preseason Check .................................................................................................................................. 66

4.8 Daily Startup Check............................................................................................................................... 67

4.9 Conditioner Operation........................................................................................................................... 68

4.9.1 Roll and Feed Draper Speed........................................................................................................... 68

4.9.2 Adjusting Roll Gap........................................................................................................................ 68

4.9.3 Adjusting Roll Timing .................................................................................................................... 69

4.9.4 Adjusting Conditioner Roll Tension ................................................................................................. 70

4.9.5 Forming Shields ........................................................................................................................... 70

Adjusting Forming Shield Height.................................................................................................... 70

Adjusting Side Deflectors ............................................................................................................. 71

Adjusting Rear Deflector (Fluffer Shield) ......................................................................................... 71

Adjusting Deflector Fins ............................................................................................................... 72

4.9.6 Unplugging the Conditioner ........................................................................................................... 72

4.10 Storing the Hay Conditioner.................................................................................................................. 73

Chapter 5: Maintenance........................................................................................................................... 75

5.1 Preparation for Servicing ....................................................................................................................... 75

5.2 Recommended Safety Procedures ........................................................................................................... 76

5.3 Removing and Installing Driveshields ....................................................................................................... 77

5.4 Lubrication .......................................................................................................................................... 78

5.4.1 Lubricants................................................................................................................................... 78

5.4.2 Greasing Procedure ...................................................................................................................... 78

5.4.3 Greasing Points ........................................................................................................................... 78

5.5 Hydraulics ........................................................................................................................................... 79

5.5.1 Hydraulic Hoses and Lines ............................................................................................................. 79

5.5.2 Hydraulic Schematics.................................................................................................................... 79

5.6 Feed Draper ........................................................................................................................................ 80

5.6.1 Adjusting Feed Draper Tension....................................................................................................... 80

5.7 Drive Belt............................................................................................................................................ 81

5.7.1 Adjusting Drive Belt Tension .......................................................................................................... 81

TABLE OF CONTENTS