Intended Use

• This product is a precision instrument and should only be used for it’s intended purpose only. Improper use or misuse

may cause SERIOUS INJURIES or could result in a potentially hazardous situation. NEVER use this product for any

other purposes.

• The safety messages, technical data involving ambient conditions and use in dry surroundings must be taken into

account at all times. .

PERMISSIBLE ENVIRONMENTAL CONDITIONS

If the tool is exposed to temperatures under 18°C or above 28°C or

atmospheric humidity higher than 90%,faulty tightening torque can

result. ALWAYS check the torque tool with an approved torque tester

before use in extreme climatic conditions. This product should

NEVER be exposed to wet or damp working environments. ALWAYS

keep work area clean and well lit.

Personal Protective Gear

ALWAYS wear personal protective gear when using the torque

tool to prevent SERIOUS INJURY. The torque tool can slip or

break.

ALWAYS wear EYE PROTECTION designed to protect your

eyes from flying objects when using this product. Particles may

be hurled upward during work with the torque tool which may

cause SERIOUS INJURY.

ALWAYS wear SAFETY GLOVES when using the torque

wrench. The torque tool can slip or break. This can cause

SERIOUS INJURY to fingers and hands

ALWAYS wear appropriate SAFETY SHOES with slip-resistant

soles and steel toe caps when using the torque tools to protect

feet and toes from SERIOUS INJURY .

OVERLOAD HAZARD!

• This torque checker can be overloaded during use and break as a

result. This might cause SERIOUS INJURY.

• NEVER use excessive force on the product.

• ALWAYS use the original accessory parts ONLY. When using

accessory parts not approved by the manufacturer there is also

the risk that they will not bear the loads.

• Check the torque checker for damage prior to EVERY application.

• NEVER use the torque checker if it has been dropped, has struck

against other objects or if objects have fallen on the tool.

FAULTY TIGHTENING TORQUE HAZARD

An uncalibrated torque checker can cause the tool and accessories to fail and produce faulty screw connections. This could

cause SERIOUS INJURY or DEATH.

• ALWAYS use tested and calibrated tools and tested torque testing equipment ONLY. Torque tools that are not fully tested

or serviced correctly risk being unable to bear the loads or could indicate faulty tightening torques.

• ALWAYS take the following safety information into account in order to prevent SERIOUS INJURY or DEATH:

• ALWAYS test the accuracy of the torque tool with an approved torque tester before use.

• A calibration certificate as per DIN EN ISO 6789 comes with the torque tools and the tool and the calibration certificate

are labelled with the identical traceable serial number.

• According to DIN EN ISO 6789 the minimum calibration interval requirement for a torque tool is 12 months or 5000 load

cycles (whichever occurs first). A firm’s own specifications or quality requirements for screwing applications can also lead

to considerably shorter calibration intervals.

Calibration should ONLY be implemented by authorized specialists, at an accredited calibration laboratory or by the

manufacturer. Under no circumstances should an attempt be made to adjust or repair a torque tool. A full repair and

calibration service is available on request, contact us for more information.

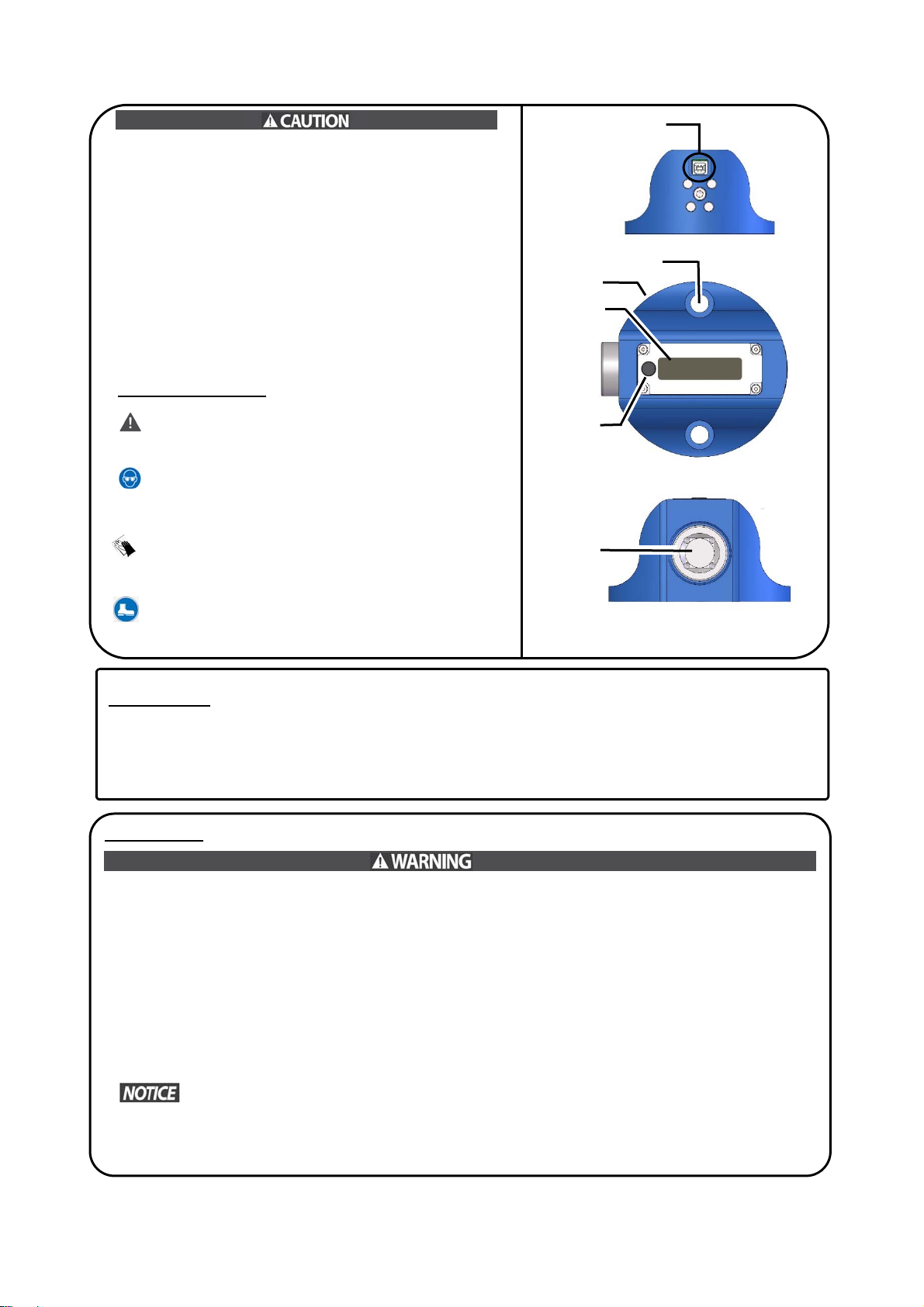

Maintenance

1.USBPowerinput

2.Mountingholes

3.Body

5.Button

6.Drive

4.Screen