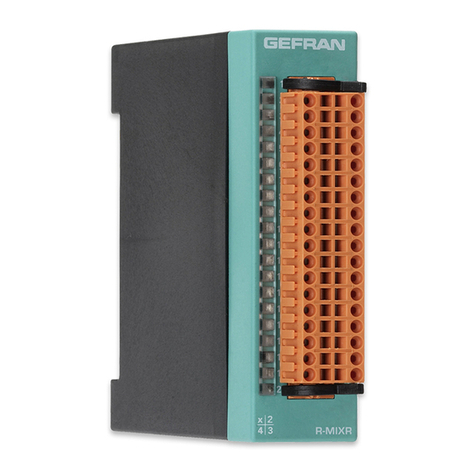

R-C3

MODULE: 3 INPUTS, ENCODERS

cod. 80122C / Edit 04 -0809 -ENG

INSTALLATION AND OPERATION MANUAL

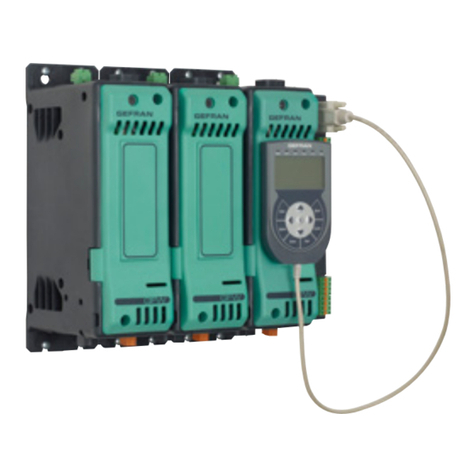

2 • INSTALLATION AND CONNECTION

This section contains the instructions necessary for correct

installation of the GILOGIK II into the machine control panel

or the host system and for correct connection of the system

power supply, inputs, outputs and interfaces.

Before proceeding with installation read the following

warnings carefully!

Remember that lack of observation of these warnings

could lead to problems of electrical safety and electroma-

gnetic compatibility, as well as invalidating the warranty.

Qualified staff

the installation and use of the system and components are only reserved

at qualified staff.

Conform use

the system and relative components are usable exclusively to the use

previewed in the manual

In order to guarantee a correct and sure operation are indispensable that

the product comes transported, stored correctly, installed, and controlled

second the previewed modalities.

Suitable for use in pollution degree 2 environment.

Open type equipment.

Notes Concerning Electrical Safety and Electromagnetic

Compatibility:

• CE MARKING: EMC Conformity (electromagnetic compatibility)

in accordance with EEC Directive 2004/108/CE.

The GILOGIK II system is mainly designed to operate in

industrial environments, installed on the switchboards or control panels

of productive process machines or plants.

Norm of applicable product EN 61131-2.

The Declaration of conformity is available on GEFRAN web:

www.gefran.com

•UL listed standard: UL508 file E198546

• BT Conformity (low tension)

in accordance with Directive LVD 2006/95/CE.

Advice for Correct Installation for EMC

Inputs and outputs connection

• The externally connected circuits must be doubly isolated.

• To connect the analogue inputs the following is necessary:

- physically separate the input cables from those of the power supply, the

outputs and the power connections.

- use woven and screened cables, with the screen earthed in one point

only. GEFRAN S.p.A. declines all responsibility for any damage

to persons or property caused by tampering, neglect,

improper use or any use which does not conform to the

characteristics of the controller and to the indications

given in these Instructions for Use.

I1 • MAIN FEATURES

• Inputs for Differential, Single Ended, Push Pull, Open Collector

encoder

• Intercepts of speed level

• 32 bit counters

• Software configuration of inputs

• Diagnostic LEDs for power supplies and alarm

• Removable connectors supplied

80122C_MHW_R-C3_0809_ENG

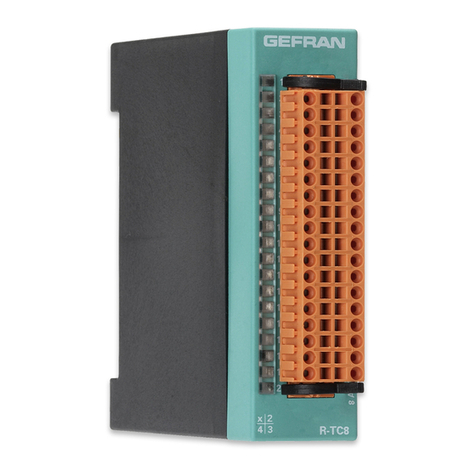

I3 • TECHNICAL DATA

- 3 encoder and counters inputs at 32 bit

- inputs for Differential, Push-Pull, Single Ended, Open Collector encoder,

limiter

- channels are independently configurable.

- filter programmable via software at

20KHz or 400KHz.

- 8..32 VDC inputs, 25 mA maximum

- input isolation >2KV

- overvoltage on inputs for 1ms max. 1kV

- Power supply: via R-BUS(x) 3.3V backplane

- For UL: supply with class 2 device

Diagnostics

• Yellow LED presence of 24V external power supplies

• Red LED Interrupt on

• Red Fail LED, module error

Encoders power supply

24VDC ± 25% 500mA max.(*) external (fed to front terminals). Power

supply is internally distributed to the 3 channels and is configurable at

+5V or 24VDC from outside.

MECHANICAL DATA

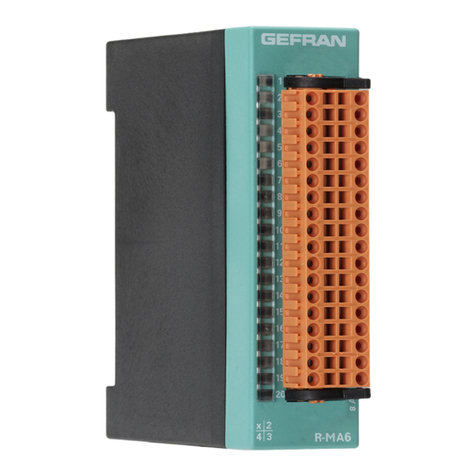

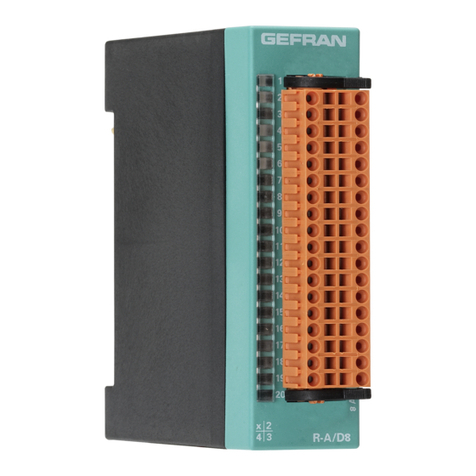

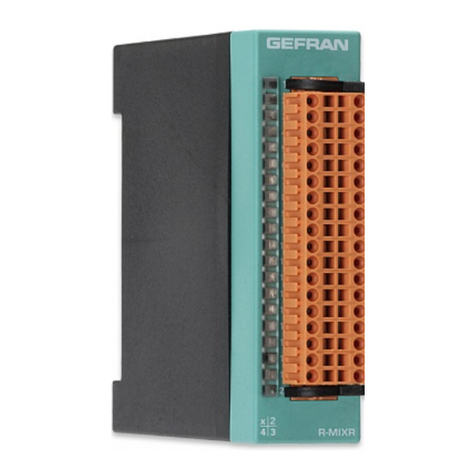

Dimensions: 92x90x25,4mm

Weight: 120 g. max

Attachment: snaps onto R-BUS(x)

Protection level: IP20

3 connectors: front 8 pin female with spring-mounted lock

AMBIENT CONDITIONS

Working temerature: 0...50°C

Storage Temperature: -20...70°C

Humidity: max. 90% Rh not condensing

For UL: Maximum surrounding air temperature 50°C