80133B_MHW_R-GCANs_05-2021_ENG 1

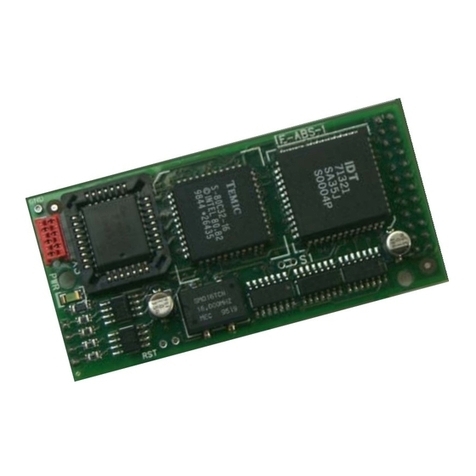

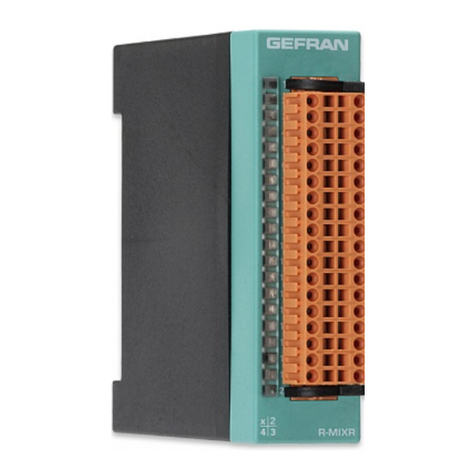

R-GCANs

CANBUS CANOPEN SLAVE GATEWAY MODULE

INSTALLATION AND OPERATION MANUAL

cod. 80133B / Edit 02 - 05/2021 - ENG

1 • MAIN FEATURES

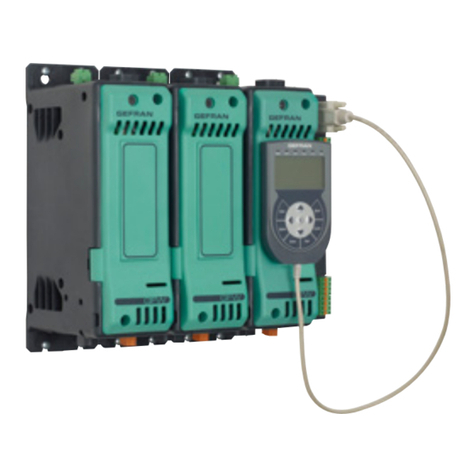

• Installation: on R-BUS (x) backplane

• DB9 male connector

• 24Vdc power supply

• Controls 16 GILOGIK II modules

2 • INSTALLATION AND CONNECTION

This section contains the instructions necessary for correct

installation of the GILOGIK II into the machine control panel

or the host system and for correct connection of the system

power supply, inputs, outputs and interfaces.

Before proceeding with installation read the following

warnings carefully!

Remember that lack of observation of these warnings

could lead to problems of electrical safety and electroma-

gnetic compatibility, as well as invalidating the warranty.

Qualified staff

the installation and use of the system and components are only reser-

ved at qualified staff.

Conform use

The system and relative components are usable exclusively to the use

previewed in the manual.

In order to guarantee a correct and sure operation are indispensable

that the product comes transported, stored correctly, installed, and

controlled second the previewed modalities.

Suitable for use in pollution degree 2 environment.

Open type equipment.

Electrical power supply

• The GILOGIK II is NOT equipped with an On/Off switch: the user

must provide a two-phase disconnecting switch that conforms to the

required safety standards (CE marking), to cut off the power supply

upstream of the system. The switch must be located in the vicinity of

the system and must be within easy reach of the operator.

One switch may control more than one systems.

• To make sure that the system very is connected to earth second the

detailed lists of the relative understood one it.

• If the system is used in applications with risk of damage to persons,

machinery or materials, it is essential to connect it up to auxiliary

security equipment. It is advisable to make sure that alarm signals are

also triggered during normal operation. The dispositif must NOT be

installed in flammable or explosive environments; it may be con-

nected to equipment operating in such atmospheres only by means

of appropriate and adequate types of interface, conforming to the

applicable safety standards.

Notes Concerning Electrical Safety and Electromagnetic

Compatibility:

CE MARKING: EMC Conformity (electromagnetic compatibility)

• Compliance with Directive 2014/30/EU

EN61131-2: Programmable controllers

Part 2: Equipment requirements and tests.

The GILOGIK II system is mainly designed to operate in industrial

environments, installed on the switchboards or control panels of pro-

ductive process machines or plants.

The Declaration of conformity is available on GEFRAN web:

www.gefran.com

• UL listed standard: UL508 file E198546

Module power supply

• Supply with class 2 device

• The power supply to the modules on the switchboards must always

come directly from an isolation device with a fuse.

• The electronic instruments and electromechanical power devices such

as relays, contactors, solenoid valves, etc., must always be powered

by separate lines.

• When the power supply is strongly disturbed by the commutation of

transistor or power units or motors, an isolation transformer should be

used, earthing the screen.

• It is essential that the plant has a good earth connection:

- the voltage between neutral and earth must not be > 1V

-theOhmicresistancemustbe<6Ω;

• In the proximity of high frequency generators or arc welders, use

adequate filters.

• The power supply lines must be separate from the instrument input

and output ones.

GEFRAN S.p.A. declines all responsibility for any

damage to persons or property caused by tampering,

neglect, improper use or any use which does not

conform to the characteristics of the controller and

to the indications given in these Instructions for Use.