Contents

1 Quick commissioning .......................................... 3

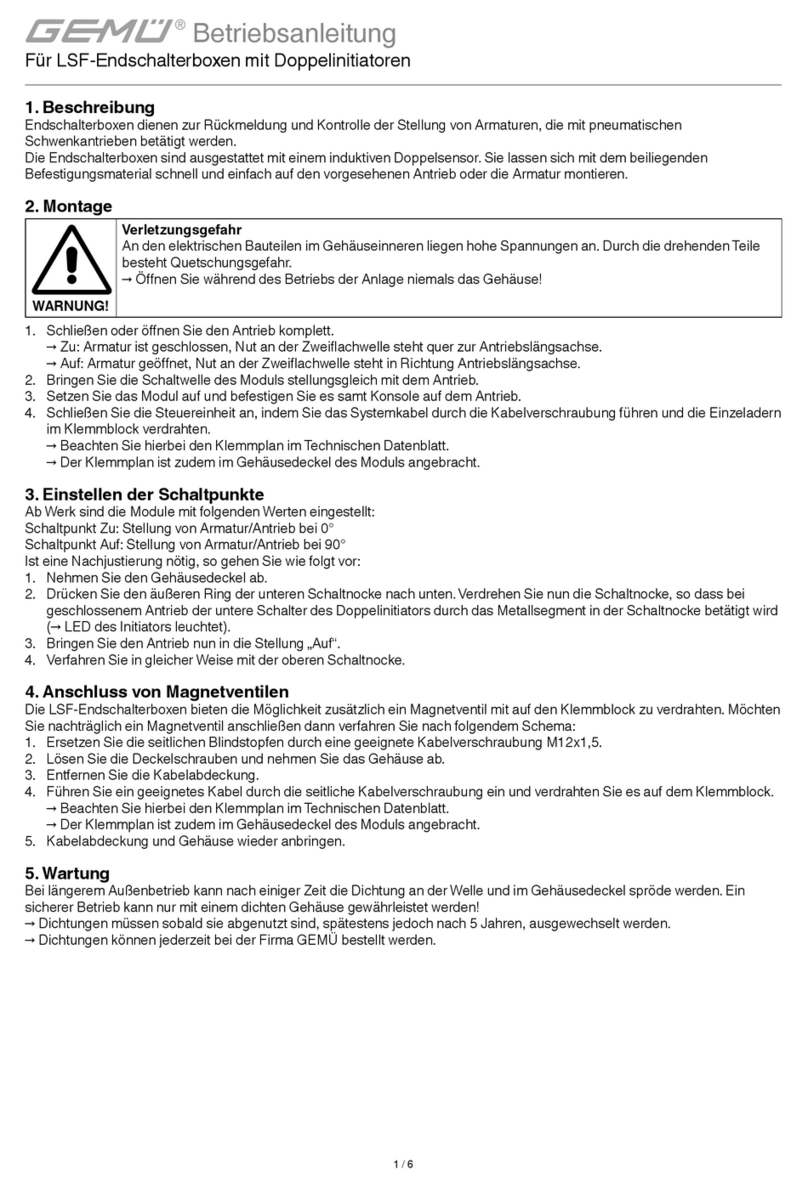

2 General information ............................................. 6

2.1 Information .................................................... 6

2.2 Symbols used ................................................ 6

2.3 Definition of terms ........................................ 6

2.4 Warning notes ............................................... 6

3 Safety information ............................................... 7

4 Product description ............................................. 7

4.1 Construction .................................................. 7

4.2 Description ..................................................... 7

4.3 Function ......................................................... 8

4.4 Fail safe function ........................................... 8

4.5 Product label ................................................. 8

5 GEMÜ CONEXO .................................................... 8

6 Intended use ........................................................ 9

7 Order data ........................................................... 10

8 Technical data ..................................................... 11

9 Dimensions ......................................................... 16

9.1 Positioner dimensions .................................. 16

9.2 Direct mounting to quarter turn actuators ... 17

9.3 Dimensions of the travel sensor, mounting

options and mounting facilities ................... 17

10 Manufacturer's information .................................. 18

10.1 Delivery .......................................................... 18

10.2 Transport ....................................................... 18

10.3 Storage ........................................................... 18

11 Assembly ............................................................. 18

11.1 Preparations for assembly to the valve ....... 18

11.2 Linear travel sensor mounting kit assembly

for remote mounting ..................................... 18

11.3 Threaded adapter assembly (linear actu-

ator) ................................................................ 18

11.4 Preparations for assembly to the valve

(quarter turn actuator) .................................. 19

11.5 Rotary travel sensor mounting kit as-

sembly ............................................................ 19

11.6 Direct mounting on linear actuators ............ 20

11.7 Remote mounting on linear actuators ......... 21

11.8 Direct mounting to quarter turn actuators ... 21

11.9 Remote mounting to quarter turn actuators 22

11.10 Checking the mechanical mounting ............ 23

11.11 Mounting the mounting bracket ................... 23

12 Pneumatic connection ......................................... 23

12.1 Connection diagram for linear actuators ..... 24

12.1.1 Connection diagram for NC valves

(Normally Closed) ............................ 24

12.1.2 Connection diagram for NO valves

(Normally Open) ............................... 24

12.1.3 Connection diagram for double act-

ing valves .......................................... 24

12.2 Connection diagram for quarter turn actuat-

ors .................................................................. 24

12.2.1 Connection diagram for NC/NO

valves (Normally Closed/Normally

Open) ................................................ 24

12.2.2 Connection diagram for double act-

ing valves .......................................... 25

12.2.3 Note for vertical pneumatic connec-

tions .................................................. 25

12.3 General information ...................................... 25

13 Electrical connection ........................................... 25

14 Fail safe function ................................................. 29

15 Commissioning .................................................... 29

15.1 With default setting (positioner supplied

mounted to the valve) ................................... 29

15.2 Without default setting (when supplied

without a valve) ............................................. 30

15.3 Setting the throttle screws ........................... 38

15.3.1 Travel time measurement during

initialization ...................................... 38

16 Operation ............................................................. 39

17 Troubleshooting .................................................. 64

18 Inspection and maintenance ................................ 67

18.1 Spare parts .................................................... 67

18.2 Cleaning the product ..................................... 67

19 Disassembly ........................................................ 67

20 General information regarding control engineer-

ing ....................................................................... 67

21 Glossary .............................................................. 70

22 Disposal .............................................................. 70

23 Returns ................................................................ 70

24 EU Declaration of Conformity in accordance with

2014/30/EU (EMC Directive) ................................ 71

25 EU Declaration of Conformity In accordance with

2011/65/EU (RoHS Directive) ............................... 72

26 Declaration of Incorporation according to

2006/42/EC (Machinery Directive) ....................... 73

27 Keyword index ..................................................... 74

GEMÜ 1436 cPoswww.gemu-group.com 5 / 76