Contents

1 General information ............................................. 4

1.1 Information ............................................... 4

1.2 Symbols used ........................................... 4

1.3 Definition of terms .................................... 4

1.4 Warning notes ........................................... 4

2 Safety information ............................................... 5

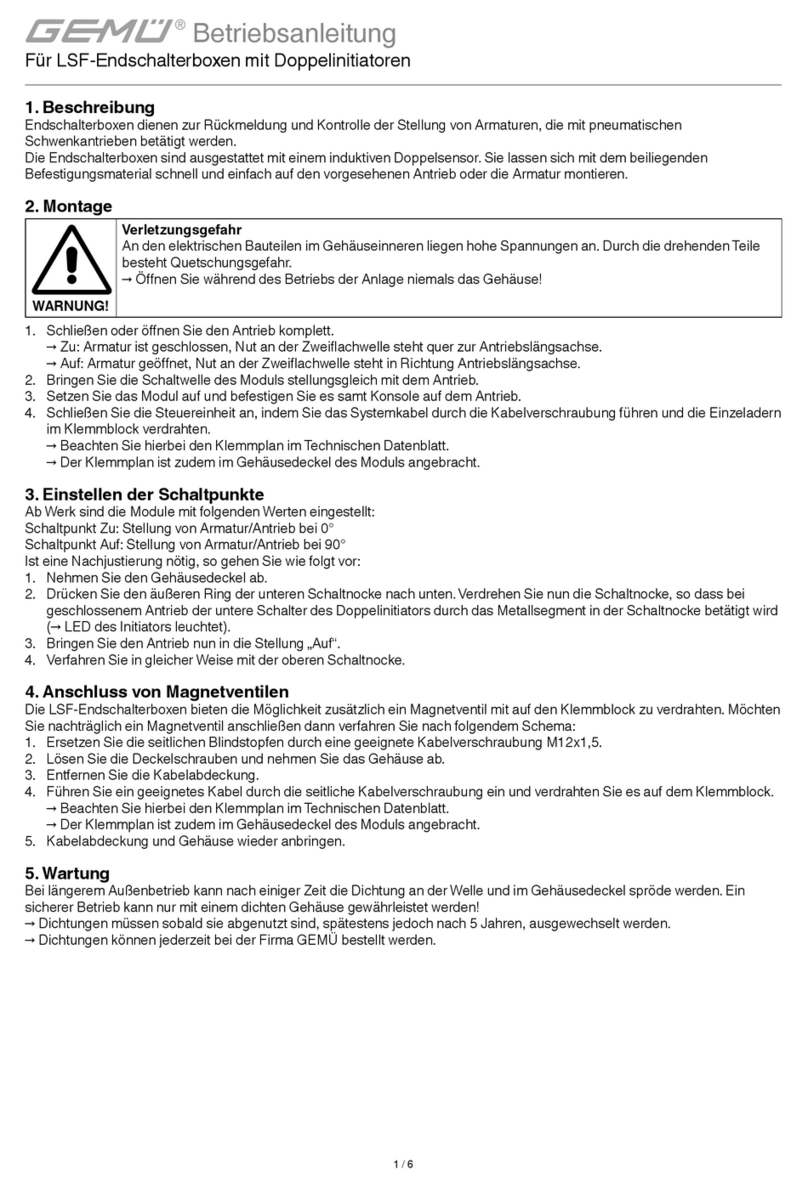

3 Product description ............................................. 5

3.1 Construction ............................................. 5

3.2 Description ............................................... 7

3.3 Function .................................................... 7

3.4 Product label ............................................ 7

4 Correct use .......................................................... 7

5 Order data ........................................................... 8

5.1 Order codes .............................................. 8

5.2 Order example .......................................... 8

5.3 Short code for actuator ............................. 9

6 Technical data ..................................................... 10

6.1 Medium .................................................... 10

6.2 Temperature ............................................. 10

6.3 Pressure ................................................... 10

6.4 Torques .................................................... 12

6.5 Mechanical data ........................................ 13

7 Dimensions .......................................................... 14

7.1 Actuator .................................................... 14

7.2 Actuator flange ......................................... 16

8 Manufacturer's information .................................. 17

8.1 Delivery .................................................... 17

8.2 Transport .................................................. 17

8.3 Storage ..................................................... 17

9 Disassembly ........................................................ 17

9.1 Preparations for disassembly .................... 17

9.2 Disassembly ............................................. 18

10 Assembly ............................................................. 19

11 Changing the rotational direction ......................... 20

12 Pneumatic connection ......................................... 24

12.1 Connecting the control medium ................ 24

12.2 Optical position indicator .......................... 24

13 Setting the end positions ..................................... 24

14 Commissioning .................................................... 25

15 Operation ............................................................. 25

15.1 Functional principle .................................. 25

16 Troubleshooting .................................................. 27

17 Inspection/maintenance ...................................... 28

17.1 General information regarding actuator re-

placement ................................................. 28

17.2 Spare parts ............................................... 29

18 Disposal .............................................................. 29

19 Returns ................................................................ 29

20 Declaration of Incorporation according to

2006/42/EC (Machinery Directive) ....................... 30

21 Declaration of conformity according to 2014/68/

EU (Pressure Equipment Directive) ...................... 31

GEMÜ GDR/GSRwww.gemu-group.com 3 / 32