V 03/13

OptiFlex 2 B Table of contents •1

Table of contents

General safety regulations 3

Safety symbols (pictograms) ...................................................................................3

Conformity of use ....................................................................................................8

Product-specific safety measures ...........................................................................8

OptiFlex 2 B manual coating equipment ....................................................8

About this manual 9

General information.................................................................................................9

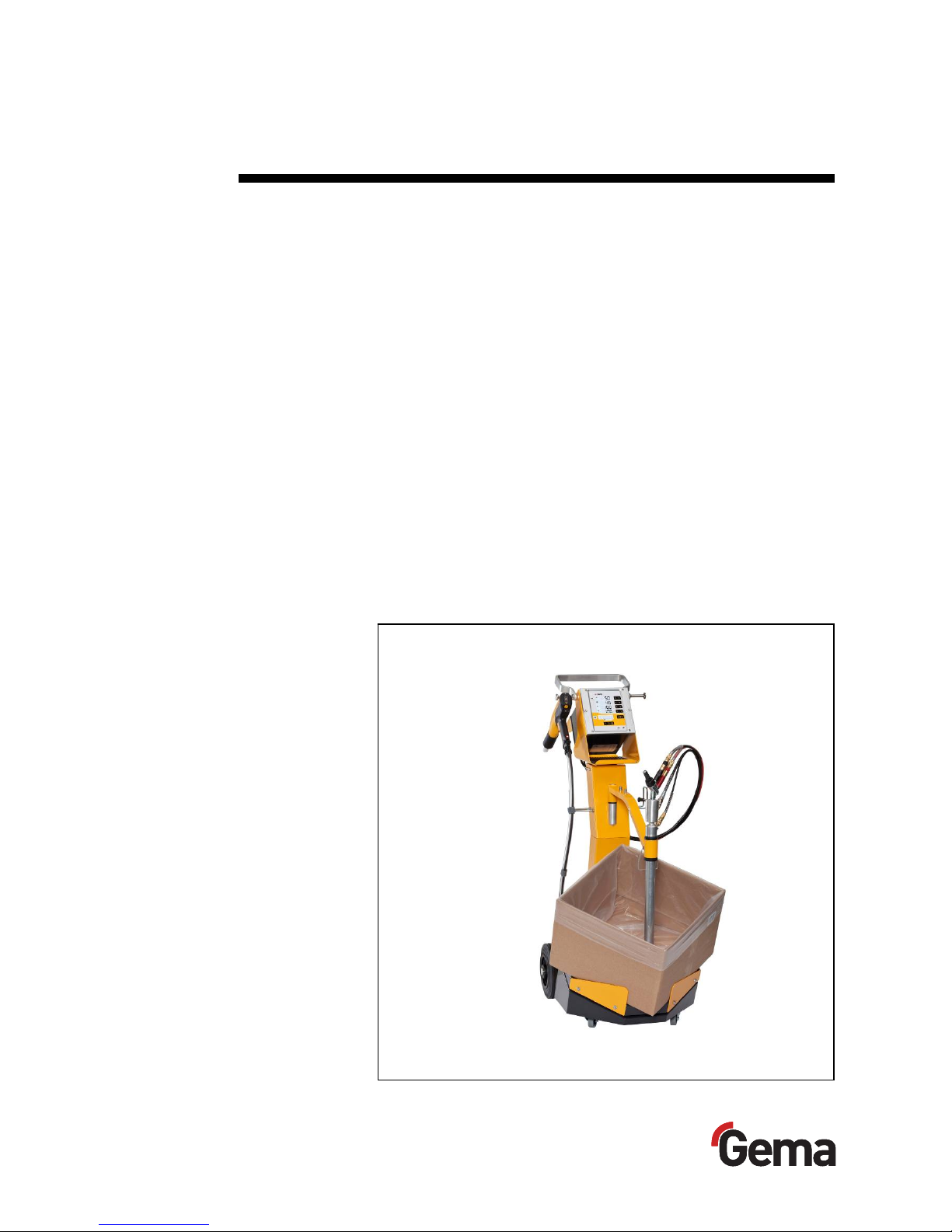

Product description 11

Field of application ................................................................................................11

Utilization ..................................................................................................11

Reasonably foreseeable misuse ..............................................................12

Technical data .......................................................................................................12

Connectable guns ....................................................................................12

Powder output (guide values) ..................................................................12

Guide values for OptiFlex 2 CG09 with the OptiFlow IG06 injector .........13

Air flow rates.............................................................................................13

Electrical data...........................................................................................13

Pneumatic data ........................................................................................14

Dimensions...............................................................................................14

Processible powders ................................................................................14

Design and function...............................................................................................15

General view ............................................................................................15

Scope of delivery...................................................................................................16

OptiFlex 2 B..............................................................................................16

Typical properties - Characteristics of the functions .............................................16

Processing the powder directly from the original powder manufacturer's

container...................................................................................................16

Freely rotating head piece........................................................................16

Start-up 17

Preparation for start-up .........................................................................................17

Basic conditions .......................................................................................17

Set-up ....................................................................................................................17

Mounting instructions ............................................................................................18

Connection instructions .........................................................................................19

Initial start-up 21

Set head piece ......................................................................................................22

Setting the device type ..........................................................................................22

Operation...............................................................................................................23

Coating .....................................................................................................23

Setting the background illumination .........................................................27

Color change .........................................................................................................28

General information..................................................................................28