3

Contents

1.0 General safety precautions ................................... 3

1.1 Dangers ................................................................ 3

1.2 Field of application ................................................ 3

1.3 Technical Specifications ....................................... 3

1.4 Construction .......................................................... 3

2.0 Installation ............................................................. 4

2.1 Coupling diagram .................................................. 6

2.2 Test run ................................................................. 7

3.0 Daily usage – user instruction .............................. 7

4.0 Maintenance ......................................................... 7

4.1. Trouble shooting................................................... 7

5.0 Liability .................................................................. 8

6.0 Declaration of conformity....................................... 9

1.0 General safety precautions

IMPORTANT – Please study all the instructions before

mounting and use.

Please keep these instructions in a safe place and in-

struct all users in the function and operation of the pro-

duct.

Do not dismantle any factory-mounted parts, since it

impedes the use of the equipment.

All electrical installations must be carried out by an

authorised electrician.

1.1 Dangers

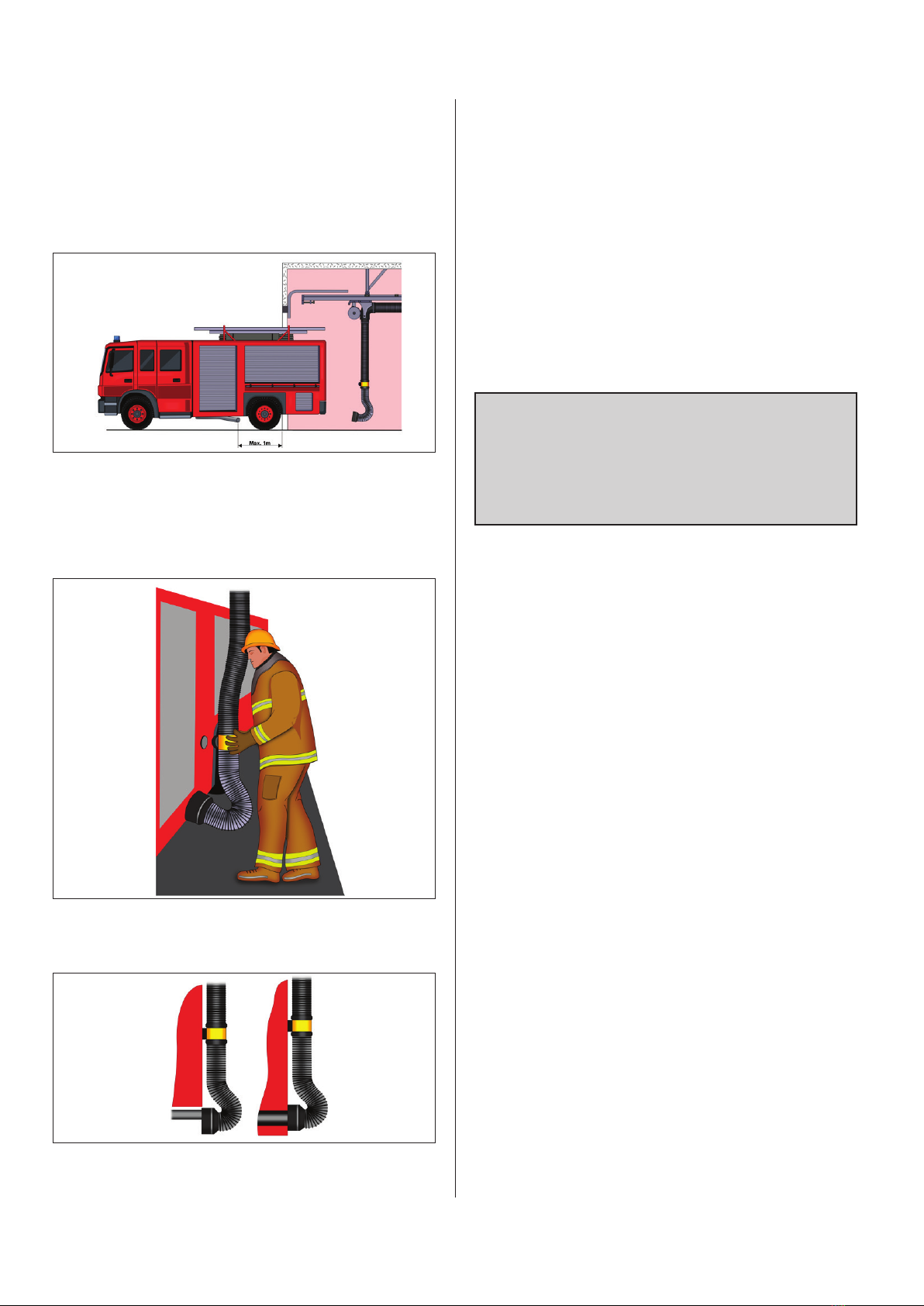

Danger of mutilation when dismounting the hose/nozzle

from the exhaust. Be careful.

Hoses mounted with spring balance F/LR: Guide it slow-

ly. If released it will accelerate out of control.

To minimize the risk of danger all instructions in this

manual must be followed carefully.

1.2 Field of application

GEOVENT Magnetic rail system is developed for the ex-

traction of exhaust and welding smoke. When installed

correctly the MRSP allows a vehicle to be placed in po-

sition in a safe manner. The hose is extended and fas-

tened to the exhaust of the vehicle.

Alternatively the MRSP can be fitted with an extraction

arm and be used for welding.

1.3 Technical Specifications

Temperature extracted air: Max. 170°C

Temperature, surroundings: Min. 0 - 50°C

If the extracted air is hotter than 170°C the standard

hose will melt. To prevent this, several precautions can

be taken. See trouble shooting in section 4.1.

Noise

The Magnetic rail system Premium in itself does not pro-

duce any noise. The noise level relies on a number of

factors, primarily the diameter of the hose and the extra-

cted air flow. If the hose is too narrow, noise will occur.

Optimal air flow

A number of factors must be taken into consideration

when selecting the hose for the Magnetic rail system

Premium. An important factor is the air flow:

Hose ø125 mm 600 m3/h

Hose ø150 mm 1.000 m3/h

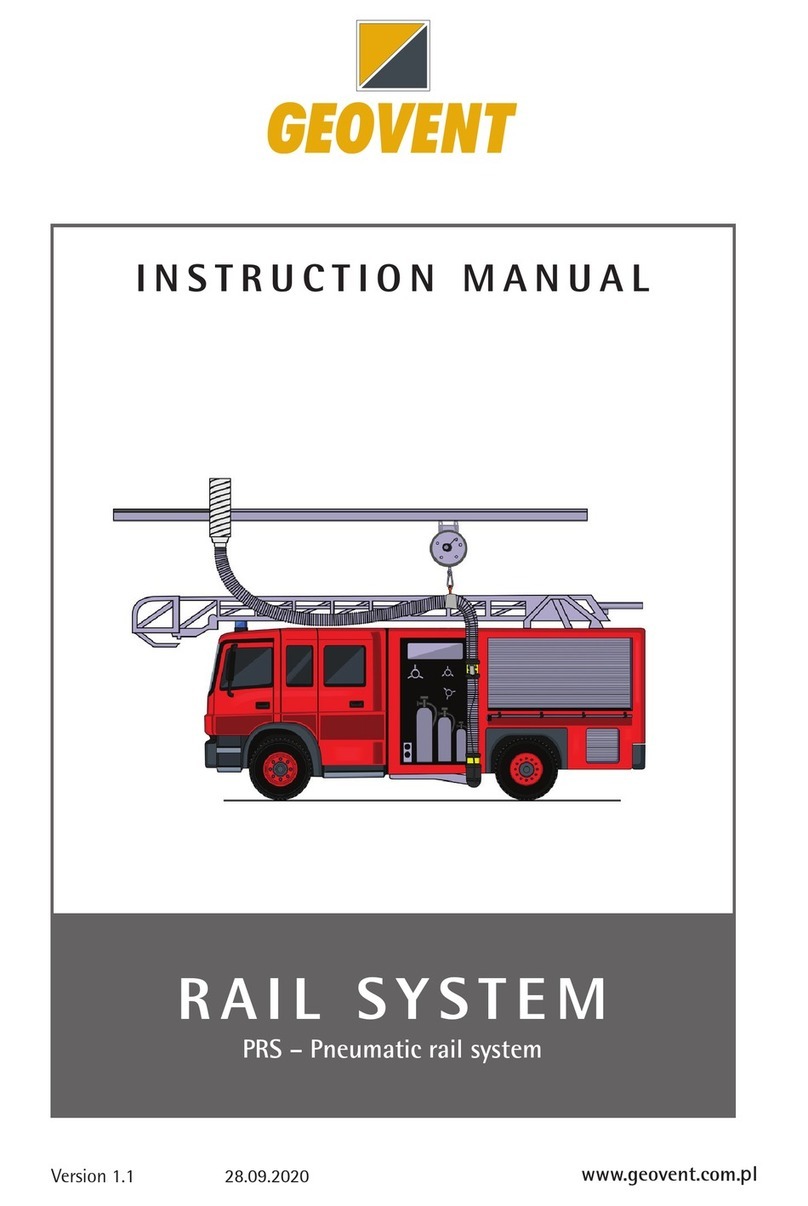

1.4 Construction

Magnetic rail system example

A: Spiro pipe ø160 with reduction valve for pressurized

air.

B: Fan MSFG-200-3 1,1kW – can deliver up to 2.100

m³/h.

C: Trolly with mounted spring balance.

D: Connection for rail system. Rails come in lengths of 2

meter and can be combined to suit your needs.

E: Suspension bracket for ceiling mounting.

F: Decoupling switch.

G: End stop