3

1.0 General safety precautions

IMPORTANT – Please study all the instructions before

mounting and commissioning.

Please keep these instructions in a safe place and

instruct all users in the function and operation of the

product.

All electrical installations must be carried out by an

authorised electrician.

Factory mounted parts must not be dismounted.

In order to secure correct suspension, in several places

two persons are required during the installation.

1.1 Danger

Letting go of the hose/nozzle when demounting it from

the exhaust pipe involves a risk of mutilation. Avoid

being hit by the nozzle – and be careful not to hit so-

meone else with it.

Hoses mounted on a trolley with spring balance F/LR:

Do not let go of the hose, when it is completely pulled

out, but keep a tight hold of the hose until it has been

totally coiled up again. If the hose slips, it will coil up

quickly, endangering people and machinery.

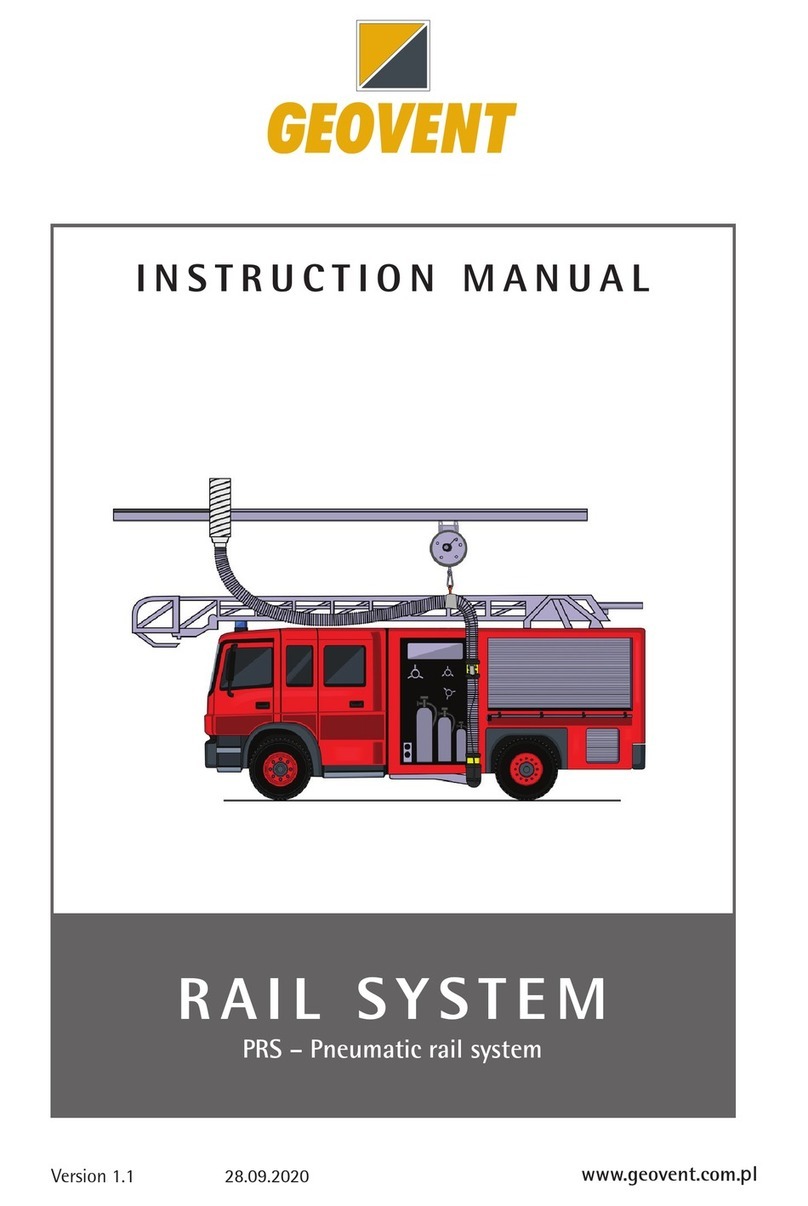

1.2 Field of application

The GEOVENT Channel Duct System is a rail system,

developed for the extraction of exhaust fumes and wel-

ding smoke. When one or several trolleys have been

correctly installed in the Channel Duct, the trolley may

be moved linearly to the area, where it is requested.

The hose is pulled down and the nozzle is fixed to the

exhaust pipe.

It is also possible to mount the hose trolley with a hose

reel (type LX or FB).

Alternatively, the Trolley may be mounted with a point

extraction arm instead (type WING or COMPACT). The

arm can rotate 360° and is suitable for the removal of

welding smoke, etc.

The Channel Duct can only be installed in such a way

that the rubber lips point either directly up or down.

The Channel Duct may not be used in areas classified

as ATEX zones, for example extraction of aluminum,

flour, textiles and wood dust and other media (eg. vapor

/ gas) which is associated with danger of explosion.

1.3 Technical data

Temperature exhaust air Max 150°C

Temperature surroundings 0 - 50°C

In special situations, where the temperature of the

exhaust air is higher than 150°C, the standard hose

may melt. In order to avoid such thing, various precauti-

ons may be taken: Please refer to the section regarding

troubleshooting, item 4.1.

Noise data

The actual Channel Duct System does not emit any

noise. The noise level depends on several factors,

primarily the relation between the diameter of the hose

and the extracted volume of air. If the hose has been

under dimensioned in relation to the required volumes

of air, wind roar may occur.

Optimum volume of air

Several factors are of importance when selecting the

optimum Channel Duct solution. Depending on the ap-

plication, the table below may be used as a guideline

for the volume of air, which is requested for the various

requirements.

Type of vehicle Recomm.

airvolume Recomm.

hose dia.

Small cars 300 m³/h ø80/ø100

Smaller private cars 400 m³/h ø100

Private cars > 3000 ccm 600 m³/h ø125

Vans/smaller trucks 800 m³/h ø125

Trucks 1000 m³/h ø150

Contractors machinery 1000 m³/h ø150

Test stand 1-2.000m³/h ø150/ø200

Contents

1.0 General safety precautions . . . . . . . . . . . . . . . . . .3

1.1 Danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 Field of application . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.4 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1 Optional equipment . . . . . . . . . . . . . . . . . . . . . . . .8

2.2 Trial run – exact adjustment . . . . . . . . . . . . . . . . . 9

2.3 Adjustment of the Trolley . . . . . . . . . . . . . . . . . . . .9

3.0 User instruction - application . . . . . . . . . . . . . . . . 10

4.0 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.0 Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.0 Declaration of Conformity according to Bilag IIA 12