3

1.0 General safety precautions

IMPORTANT – Please study all the instructions before

mounting and commissioning.

Please keep these instructions in a safe place and

instruct all users in the function and operation of the

product.

Do not dismantle any factory-mounted parts,

since it impedes the commissioning of the

equipment.

An authorised electrician must carry out all

electrical installations.

1.1 Danger

Explosive media – The Extraction arm is not suitable

for the extraction of aluminium dust, our, textile dust

nor for sawdust or other media, which are connected

with danger of explosion, without specic approval from

Geovent A/S.

Placing the hand between the spring and the carrying

arm could involve a risk of mutilation.

Demounting the spring is deadly dangerous.

1.2 Field of application

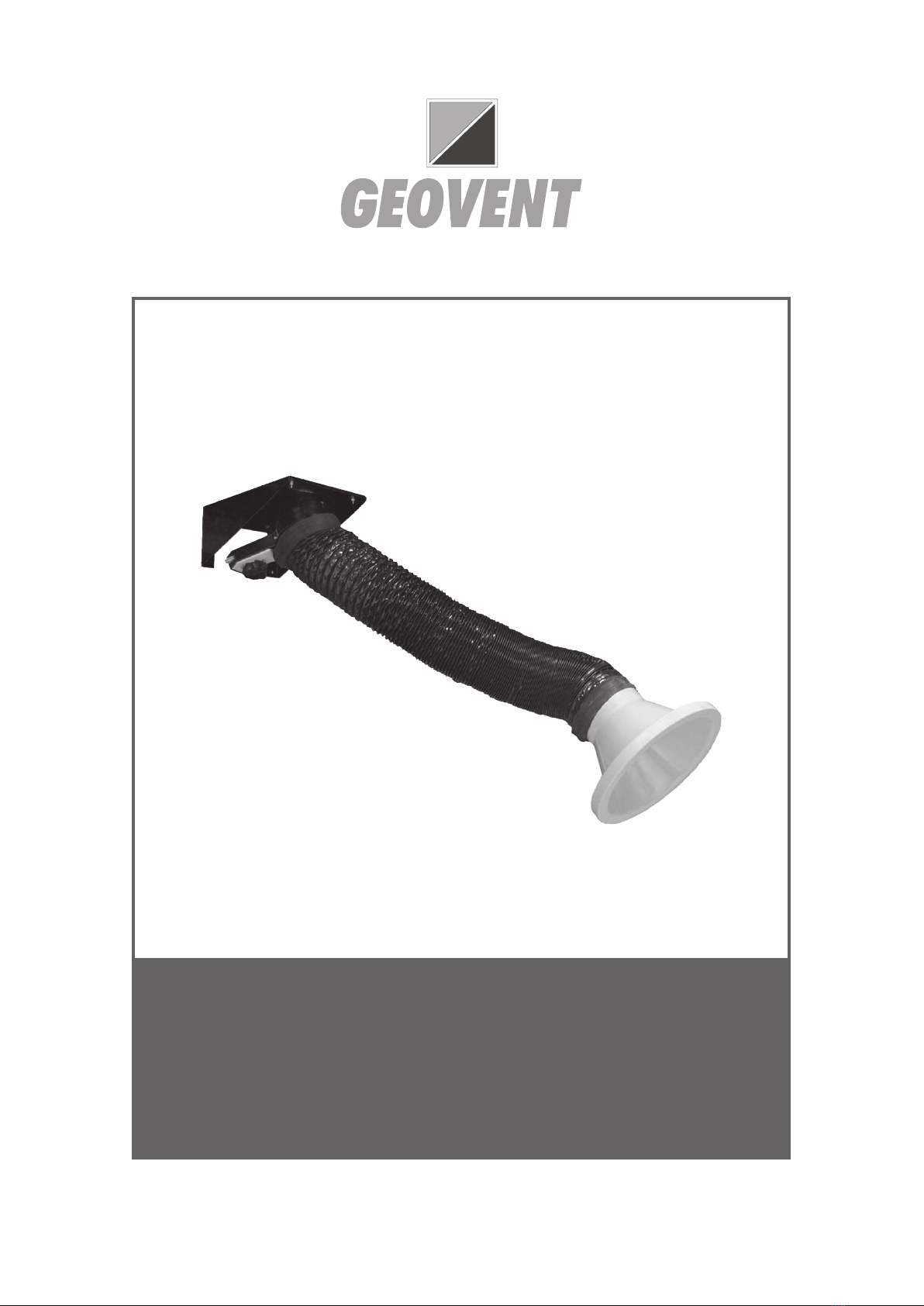

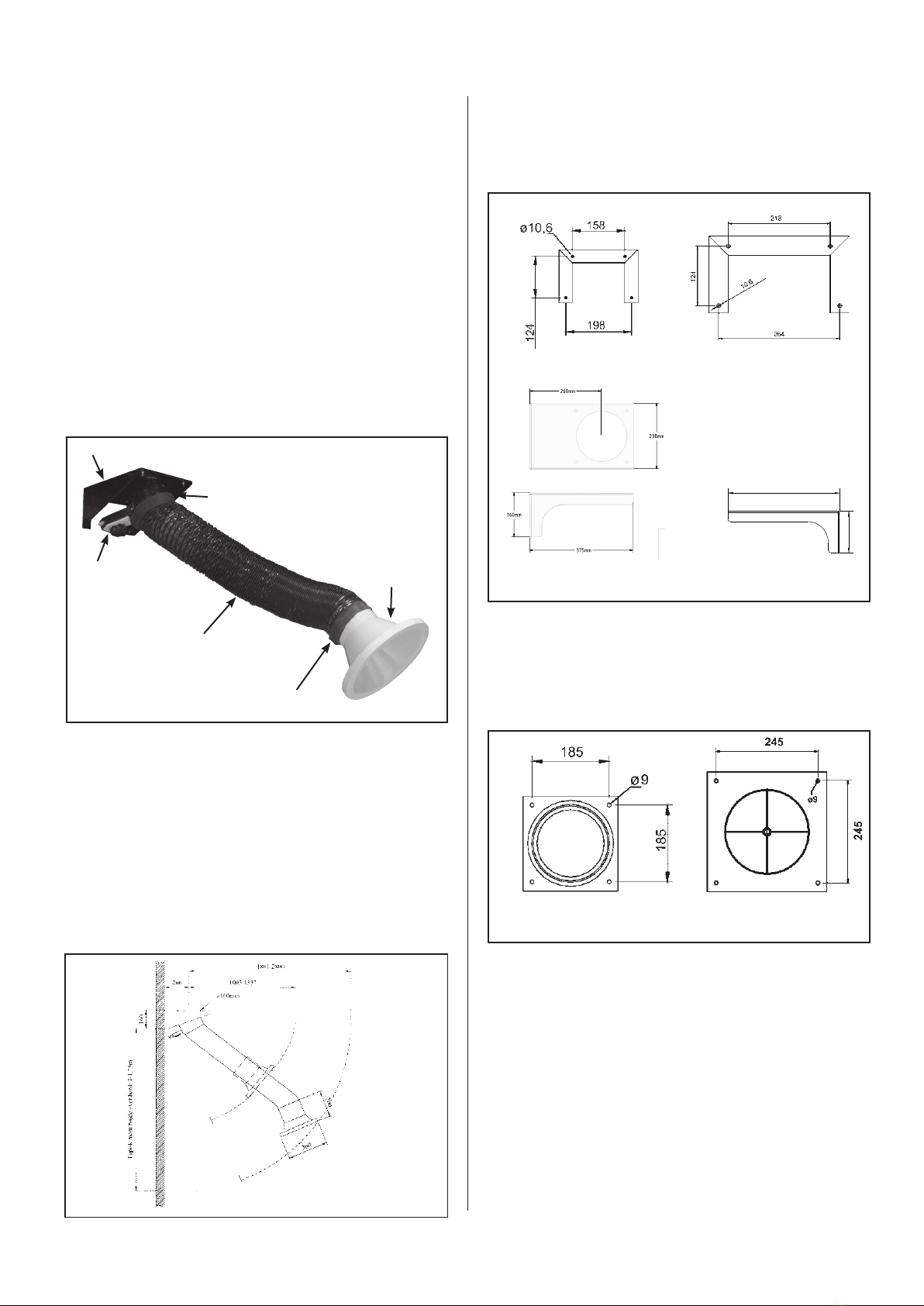

The COMPACT arm is the ideal Extraction arm for the

extraction of welding smoke, grinding dust, fumes,

etc. when there is only limited space available in the

working area.

Since the arm is telescopic, it only requires minimum

space, and still it is a perfect combination between the

large arms with major suction capacity and the smaller

arms, which are easy to position.

The Extraction arm is not suitable for the extraction of

aluminium dust, our, textile dust nor sawdust or other

media, which are connected with danger of explosion,

without specic approval from Geovent A/S.

Under no circumstances may the balancer, which

is mounted on the ceiling bracket, be loosened or tigh-

tened to the extent that the inner spring breaks. There-

fore, be careful in order to avoid loading the spring in

the outer areas.

The hose may be damaged and leaky via outer loads,

e.g. by a screwdriver. Avoid such load in order to safe-

guard a long life.

1.3 Technical data

Recommended ow area

Hose dimension:

Ø160 800-1000 m³/h

Ø200 1000-1500 m³/h

Length: 1-2 and 1,5-3 m

Via an extension arm up to: 7 m

Hose Max. Temp. (depends onthe type) Up to 150°C

1.4 Construction

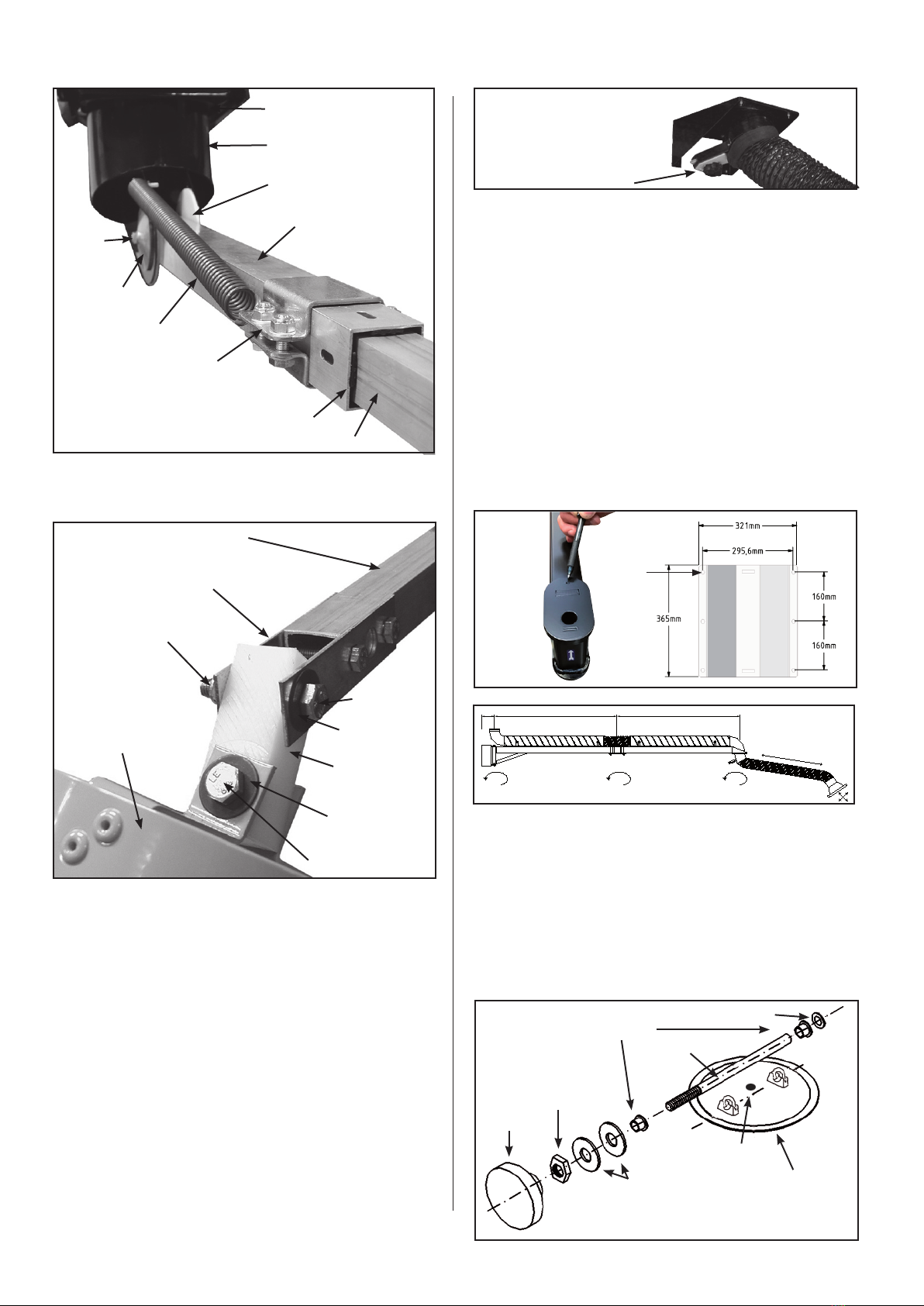

Ceiling bracket: Powder enamelled in black RAL 9005

steel bracket, the rotary joint of the bracket can rotate

360°.

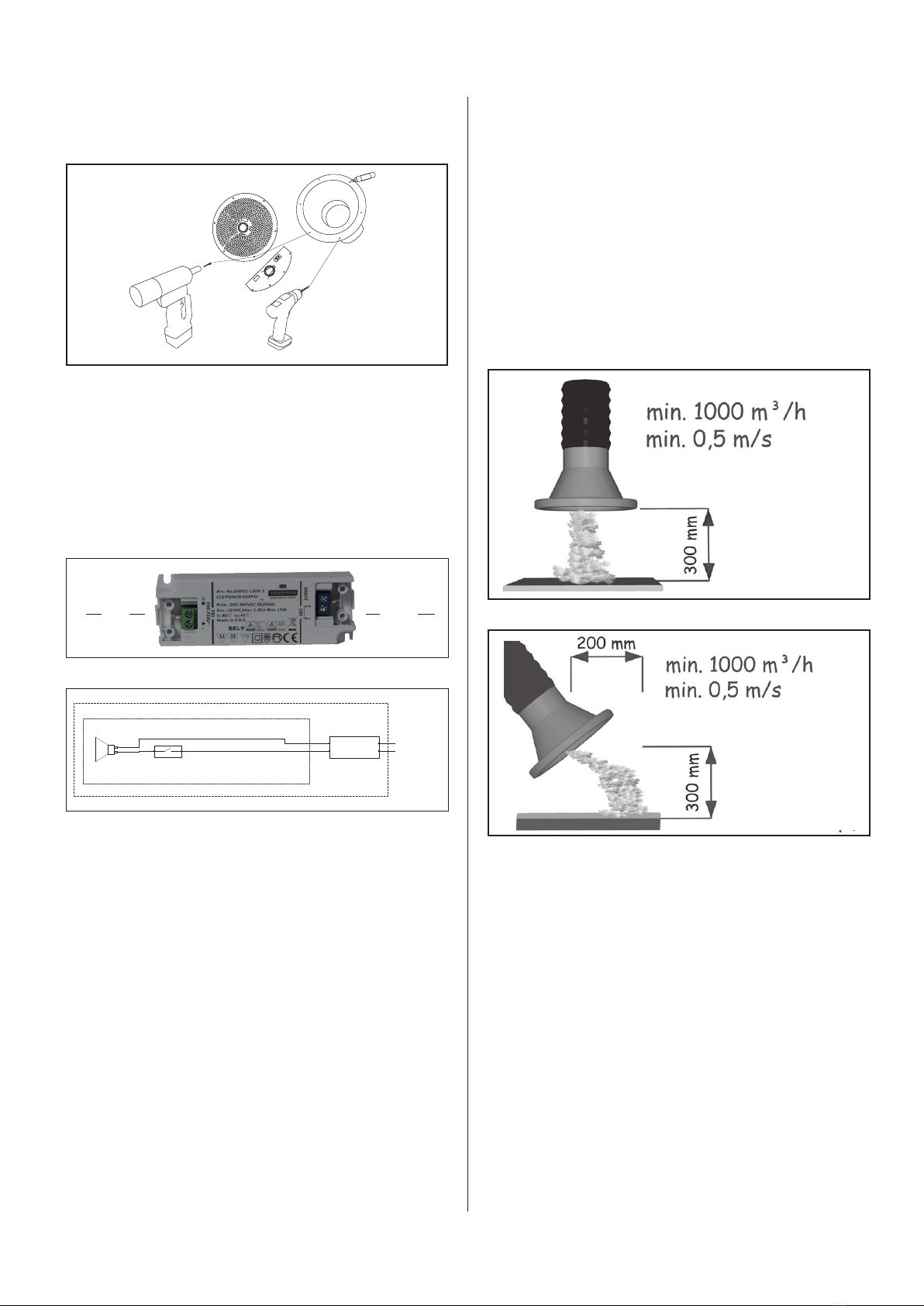

Hood: The light-weight aluminium hood ø160 or ø200

mm is equipped with an integrated handle.

The hood is powder enamelled in RAL 1007.

May be rotated in all possible positions.

Contents

1.0 General safety precautions.................. 3

1.1 Danger .................................3

1.2 Field of application . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Technical data............................ 3

1.4 Construction – table of dimensions ........... 3

2.0 Installation .............................. 4

2.1 Optional equipment ....................... 5

2.2 Connection ..............................5

2.3 Trial run – exact adjustment ................. 5

3.0 User instruction – application ................ 5

4.0 Maintenance.............................6

5.0 Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.0 Declaration of conformity ................... 7

200

200

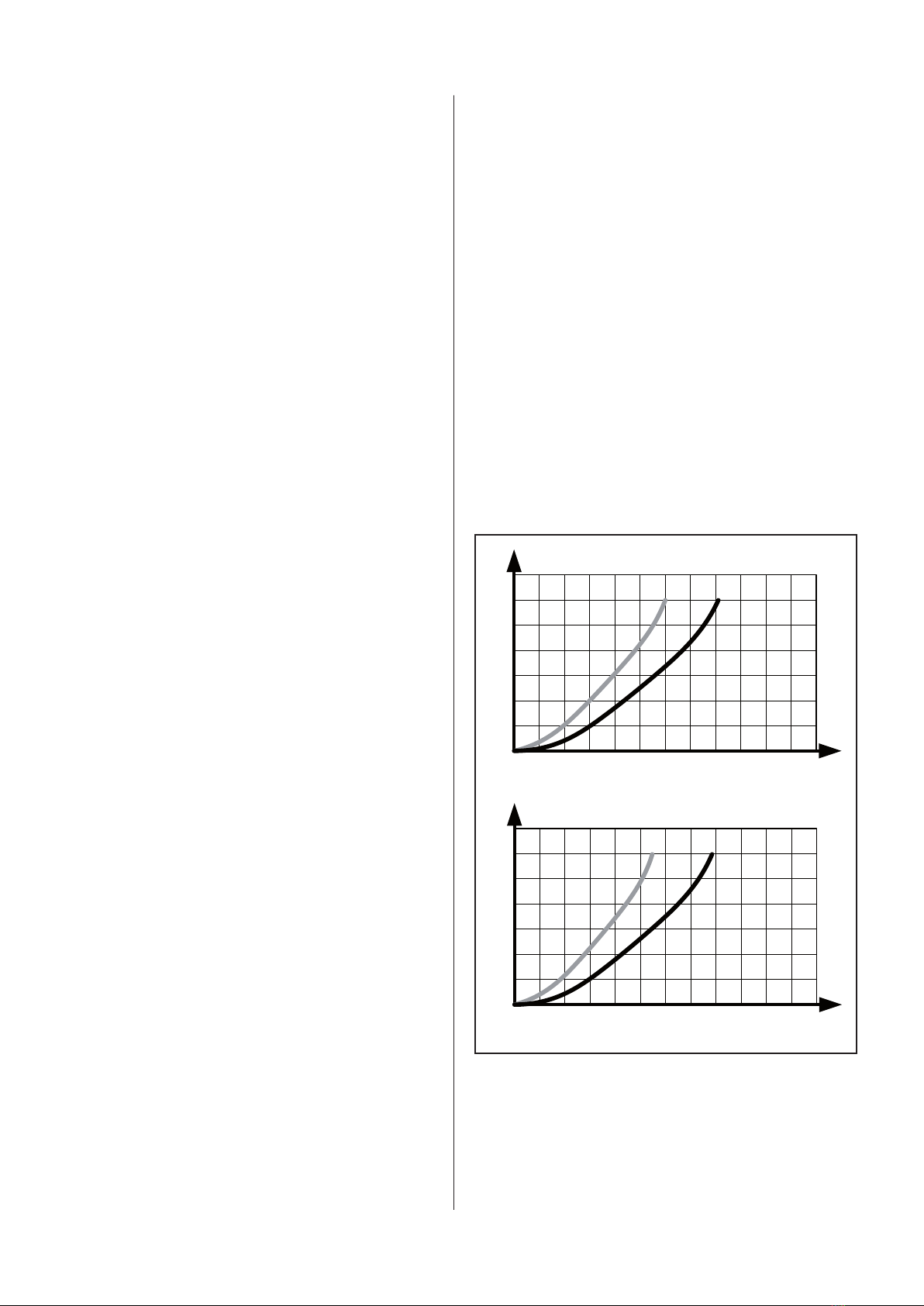

Volumenstrøm [m³/h]

[Pa] COMPACT arm 1,5-3m Tryktab

400 600 800 1000 1200 1400 1600 1800 2000 2200

400

600

800

1000

1200

1400

ø160 ø200

200

200

Volumenstrøm [m³/h]

COMPACT arm 1-2m Tryktab

400 600 800 1000 1200 1400 1600 1800 2000 2200

400

600

800

1000

1200

1400

ø160 ø200

COMPACT arm 1-2m Pressure drop

COMPACT arm 1,5-3m Pressure drop

Airow (m³/h)

Airow (m³/h)