7

©

SMA 40 APV-48.H1 / 01.01.2021 / V01.00-EN

Technical manual

Noise emission values in accordance with the DIN

EN 60745-1 standard:

Vibrations:

Note:

The measured values listed above depend on the

materials and operating procedures used and may

therefore be exceeded under other operating

conditions.

Using the machine to create bevels with a width

greater than that permitted will result in a

disproportionally large reduction in the machine’s

on-time and the service life of the indexable carbide

inserts. The vibration and noise emission values

will increase accordingly.

To prevent overloading the machine and to avoid

operator fatigue it is very important to observe the

maximum power-on periods especially when

machining wide bevels or high-strength materials.

Value Un-

certainty

Noise emission [dB (A)]

Emission sound pressure

level LpA 89 3

Peak emission sound pres-

sure level at workplace

(during milling operation)

LpGpeak 105 3

Sound power level LWA 100 3

Total vibration value

(tri-axial vector sum) Appropriate to

DIN EN 60745:

Measured vibration emission

value

ah = 3,0 m/s²

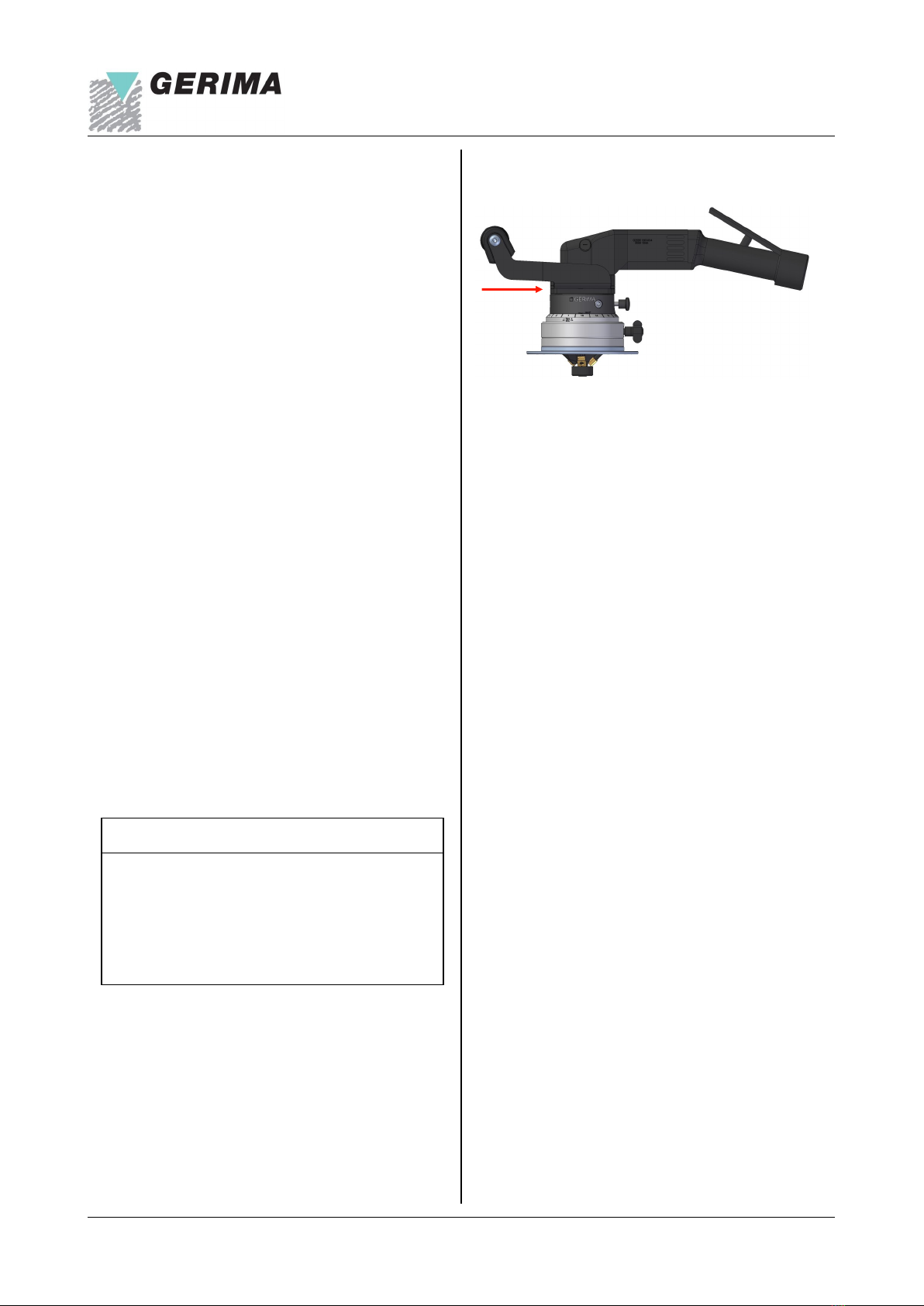

Work process:

- 30° milling head

- 5 mm bevel width (C) in

12 mm steel sheet S 355 Uncertainty

K = 1,5 m/s²

Power-on time (POT):

To avoid damaging the machine, it is essential to

be monitor how long the machine has been

operating continuously (‘power-on time’).

The compressed air that powers a pneumatic drive

also serves to cool the motor as well. Pneumatic

tools can therefore be operated for longer periods

than electrically powered tools.

However, if the machine is subjected to particularly

extreme loads (e.g. when machining wide bevels or

very hard or tough materials) and/or if the machine is

run for very long periods, the air cooling may still be

insufficient to prevent overheating of the milling drive

unit. If the operator continues to use the machine,

the milling drive unit may overheat and be damaged

as a result.

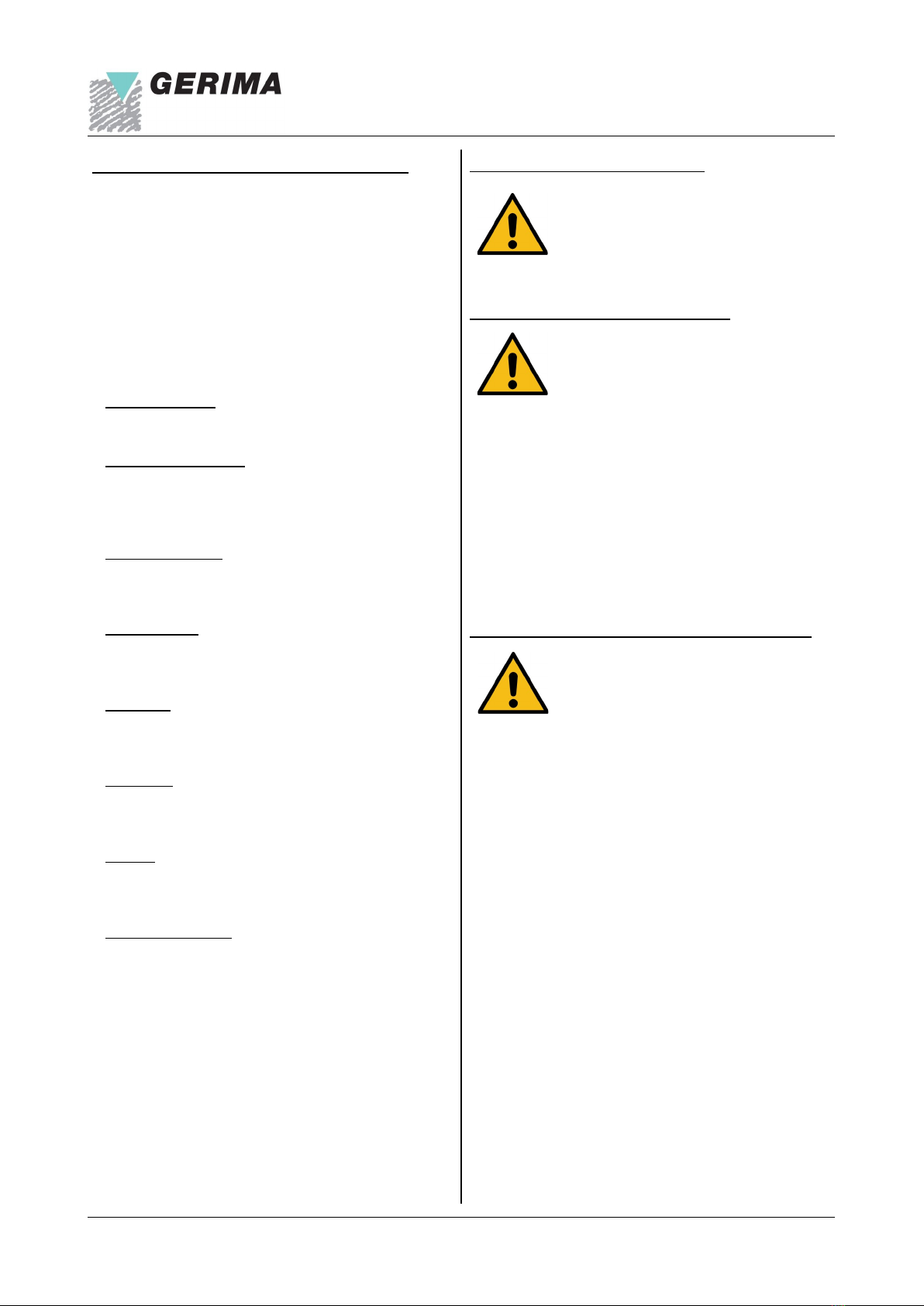

(C=bevel width, POT=power-on time)

The power-on time is always expressed as a

percentage of one hour.

Example:

If the power-on time is specified as 50 %, then you

can use the machine to mill bevels for a maximum of

30 min. in an hour and must then leave the machine

to cool for 30 min.. If the machine is subjected to

heavy loads, the power-on time might be 20 %,

which means it can be used for 12 min. in any hour

and must be left to cool for 48 min.. Before

completely switching off the machine, we

recommend running the machine for one or two

minutes in idle mode (unloaded) so that fan can

continue to draw cool air through the machine.

Do not overload the machine!

The machine can become overloaded if, for

example, it continues to be used even though the

bevel being cut is too large for the material being

milled, or if the cutting inserts have become blunt

and therefore unable to penetrate the material.

Such conditions can lead to large machine vibrations

or even machine breakdown.

To prevent this sort of damage when milling large

bevels and/or hard materials, never try to machine

the bevel in a single pass, always use multiple

passes, and do not forget to change the carbide

inserts before they become blunt or worn.

Material strength C max. POT max.

Aluminium, copper, brass 20mm 80%

Steel up to 400 N/mm² 15mm 60%

Steel up to 600 N/mm² 15mm 50%

Steel up to 900 N/mm² 15mm 40%

Stainless steel 8mm 40%

Total vibration value

(tri-axial vector sum) Appropriate to

DIN EN 60745:

Measured vibration emission

value

ah = 6,0 m/s²

Work process:

- 30° milling head

- 8 mm bevel width (C) in

12 mm steel sheet S 355 Uncertainty

K = 1,8 m/s²