6 7

4. Operating Procedure

With your Recipro handpiece adjusted for stroke and with a selected tool fitted, connect the

Gesswein Power Hand Controller to an electrical supply and the Recipro to Controller.

Set the slide Rheostat on the controller to “Low” or the “0” position. Put the Controller Main

Switch to the “ON” position, which lights up a pilot light that indicates your Recipro is ready

to use.

To increase the speed of the Recipro handpiece, move the Slide Rheostat toward “High”

or “10” and the desired reciprocating frequency and begin working. When the work is com-

pleted, put the Main Switch to “OFF.”

To operate your Recipro by using the optional Variable-Speed Foot Rheostat or optional On/

Off Foot Switch, please refer to the Power Hand Controller Instruction Manual for proper con-

nection. The handpiece will not reciprocate until the foot rheostat/switch is depressed. The

rheostat provides infinitely variable speed control; the switch only turns handpiece on and off

(operates at speed selected on control unit).

5. Precautions

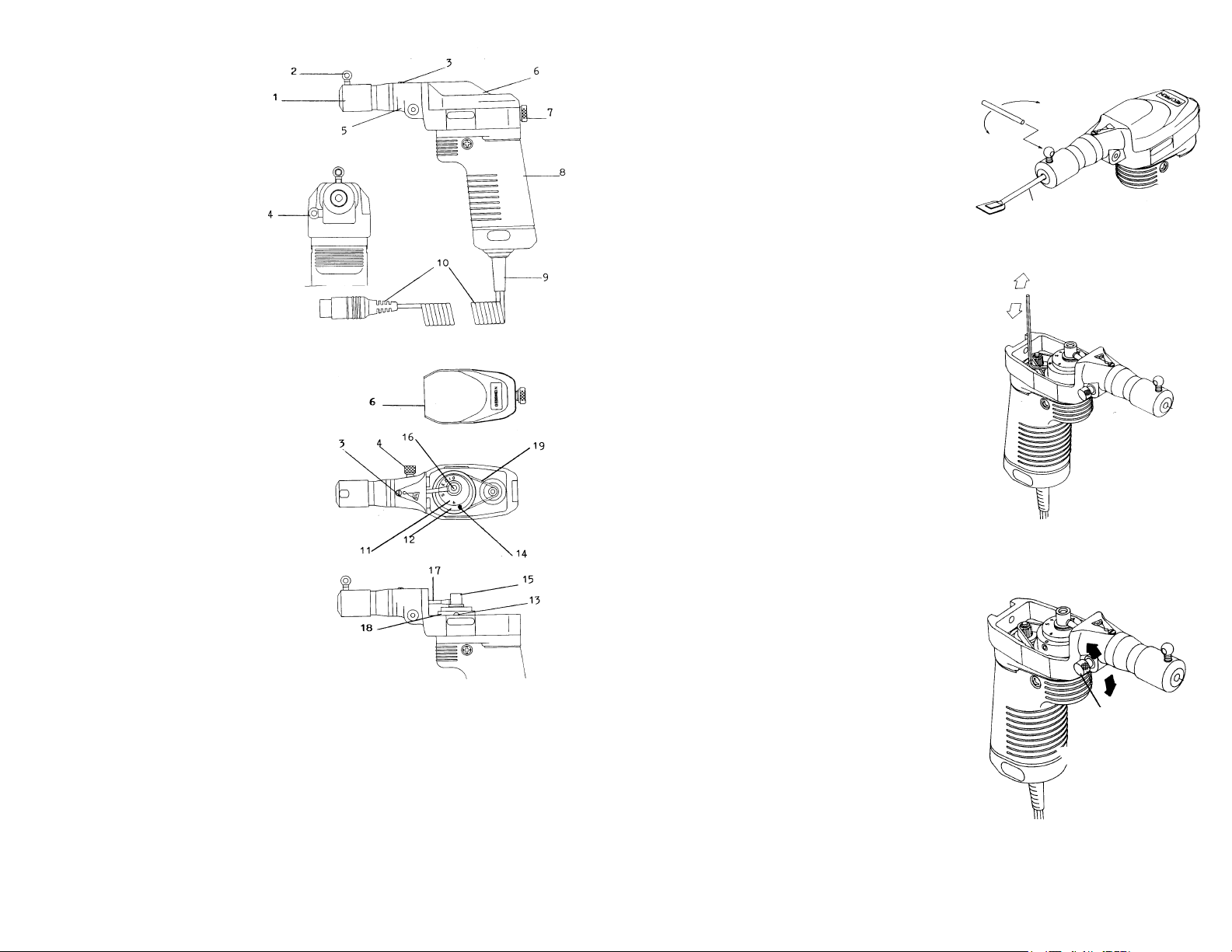

A. For your personal safety, do not operate the Recipro handpiece with the cover removed.

Operation without the cover secured with the cover screw can cause foreign objects to

fall into the high-speed moving cam parts, causing bodily injury and handpiece damage.

B. Before operating your Recipro, be sure the desired tool is properly secured in the spindle

aperture.

C. Do not attempt to change tools or use the floating head feature while the handpiece is

operating.

D. During use, avoid pushing too hard on the work tool or exceeding torque capacity of the

Recipro motor.

E. After stoning operations with lubricants, prevent oil-abrasive slurry from entering the

handpiece by holding the Recipro with spindle pointed down.

F. When the Recipro is used against vertical walls of a workpiece, a hammering effect may

be felt in the handpiece and work tool. Although the Recipro has a spring-loaded cush-

ion to prevent damage caused by hammering or the restriction of stroke movements,

prolonged use of this nature can cause damage to the spindle, ball joint, metal bearings

and work tool.

G. Applications in which a sharp work tool strikes the surface of a workpiece should be

avoided.

H. Whenever possible, avoid using the Recipro in high humidity.

I. Always disconnect the Recipro from the Controller by the plug, not the cord.

J. Under normal circumstances, the Recipro handpiece will not overheat. If your Recipro

does overheat, please contact the Gesswein Repair Department.

6. Maintenance

Lubrication

It is necessary to lubricate the Recipro head assembly parts engaged in reciprocating

action. Lubrication should be scheduled for this portion of your Recipro once for each

eight hours of use.

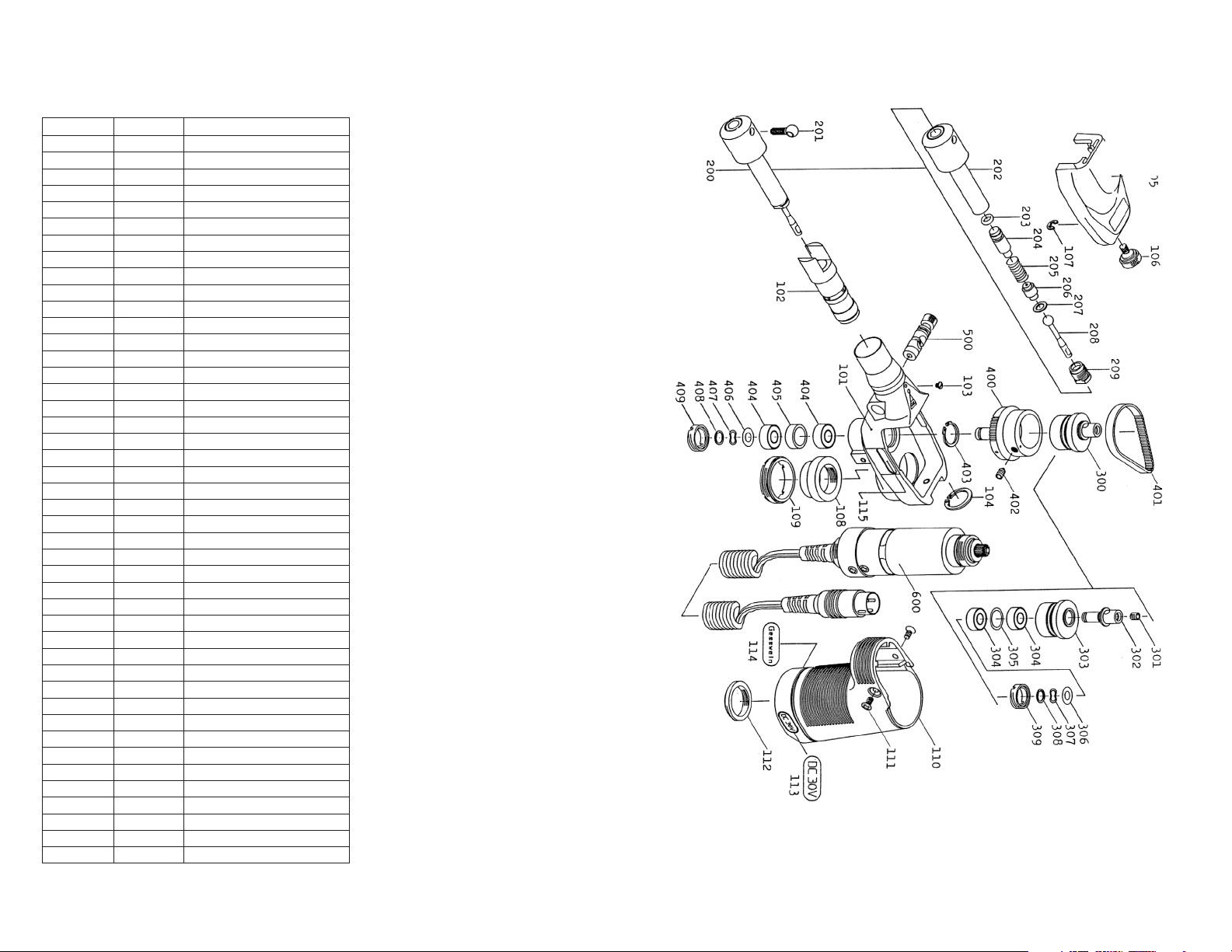

The Recipro must periodically receive two small drops of oil. Lubrication is done through the

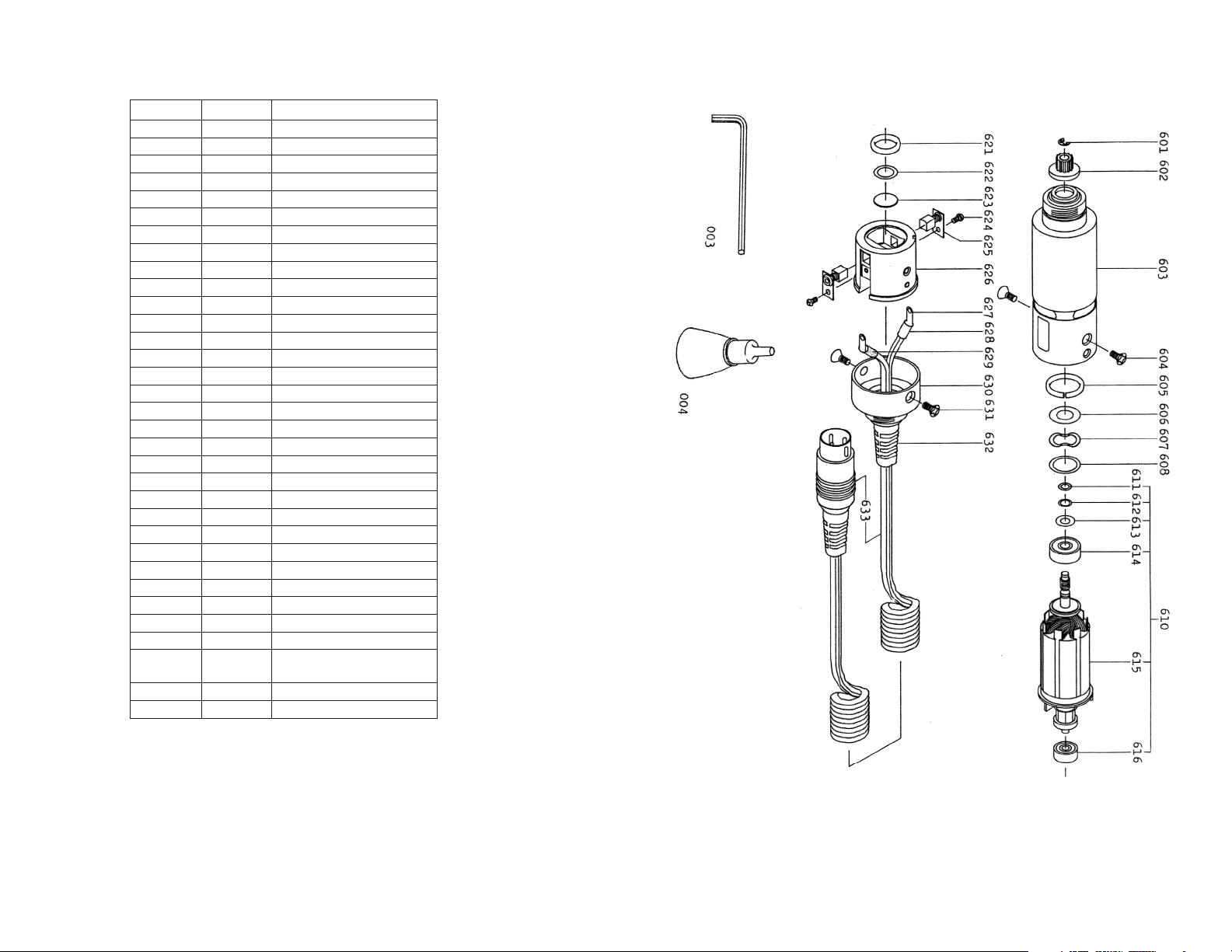

Lubrication Hole after removal of the small screw (part #103 – see p. 8-9 for parts drawing)

located in the top-front of the handpiece body. Two drops of light machine oil like the Spindle

Oil provided with the Recipro is sufficient to keep the spindle assembly working smoothly.

Cleaning

With prolonged use of the Recipro handpiece, oil, abrasives and dust from the workplace

atmosphere are likely to accumulate around and in the spindle aperture and under the

body cover. This accumulation could cause malfunction and damage to moving compo-

nents if not removed.

To remove the dirt from under the body cover, use a dry brush or a detergent-moistened

cloth. Periodically clean the spindle aperture with a cotton swab. Do not use paint thinner

or alcohol as a cleaner.

When the external surfaces of your handpiece become dirty, wipe with a cloth slightly

saturated with neutral cleaning liquid. Again, do not use a volatile liquid such as paint

thinner or alcohol.