2URS 60, URS 61 - Installation & Operating Manual - 819634-01

Contents

Content of this Manual....................................................................................................................................4

Scope of delivery/Product package................................................................................................................4

How to use this Manual...................................................................................................................................5

Illustrations and symbols used.......................................................................................................................5

Hazard symbols in this Manual.......................................................................................................................5

Types of warning .............................................................................................................................................6

Specialist terms/Abbreviations.......................................................................................................................7

Usage for the intended purpose...................................................................................................................... 8

Admissible accessories, dependent on the required safety integrity level ....................................................9

Improper use .................................................................................................................................................10

Basic safety notes .........................................................................................................................................10

Required personnel qualifications................................................................................................................10

Notes on product liability..............................................................................................................................10

Functional safety, safety integrity level (SIL) ............................................................................................... 11

Performing an annual function test ...........................................................................................................11

Reliability data to EN 61508 ..........................................................................................................................12

Function .........................................................................................................................................................13

Possible combinations of functions and equipment ...................................................................................14

Technical data ...............................................................................................................................................16

Example rating plate/identification of URS 60/URS 61 ................................................................................18

Factory settings.............................................................................................................................................19

Safety control unit URS 60 ........................................................................................................................ 19

Safety control unit URS 61 ........................................................................................................................ 19

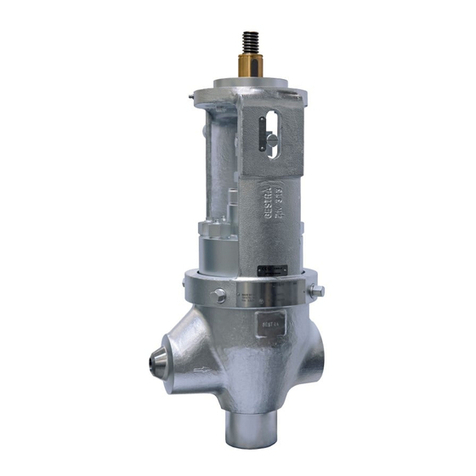

Functional elements and dimensions...........................................................................................................20

Installing the URS 60/URS 61 safety control unit.........................................................................................21

Wiring diagram of the URS 60/URS 61 safety control unit...........................................................................22

Electrical connection.....................................................................................................................................23

Bus line, cable length and cross-section ...................................................................................................23

Connecting the 24V DC power supply .......................................................................................................23

Connecting the 24V DC I/O interface .........................................................................................................23

Instructions for connecting the safety circuit............................................................................................. 23

Notes on connecting inductive loads......................................................................................................... 23

Wiring diagram of CAN bus system..............................................................................................................24

Example ...................................................................................................................................................24

Important notes on connecting the CAN bus system..................................................................................24