If the equipment is used in contaminated areas

there is a risk of severe injuries or death caused

by harmful substances in or on the equipment.

Before working on the equipment make sure

that it is completely decontaminated. Always

wear the protective clothing prescribed for

contaminated areas when working on the

equipment.

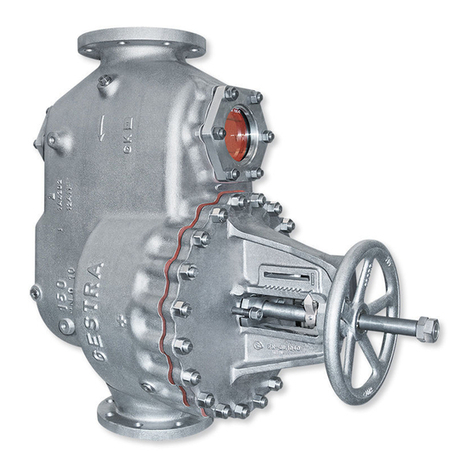

The equipment must only be used with fluids

that do not attack the material and the gaskets

and sealings of the equipment. Otherwise leaks

may occur and hot or toxic fluid could escape.

The equipment and its component parts must

only be mounted or removed by qualified

personnel. A qualified person must be

acquainted with and experienced in the

following:

Making pipe connections.

Selecting suitable lifting gear and

understanding the rules for its safe use.

Working with dangerous (contaminated, hot

or pressurized) fluids.

If unsuitable lifting gear is used or the gear is

used improperly the equipment or parts of it

could fall down.

Make sure that only qualified personnel lifts

the equipment or parts of it.

Make sure that nobody is standing or

working below the hoisted equipment.

Make sure that the lifting gear is of sufficient

strength for the load to be hoisted and that

the load is properly secured and attached to

it. For more information on the nature and

weight of the components and safe lifting

points please contact the manufacturer.

Make sure that all locally applicable

regulations on safety and the prevention of

accidents are strictly adhered to.

If the admissible temperature and pressure

limits are exceeded the equipment may be

destroyed and hot or pressurized fluid may

escape. Make sure that the equipment is only

operated within the admissible service range

and limits.

For more information on limits and pressure &

temperature ratings see name plate and the

section "

Technical Data

".

The equipment may be damaged if the

connection of the equipment with the pipe is not

stable enough or the equipment is not

sufficiently supported. Hot or pressurized fluid

may escape. Only qualified personnel is allowed

to install and connect the equipment.

If the support of the equipment during

installation is insufficient the equipment might

fall down, thereby causing bruises or injuries.

Make sure the equipment is safely held in place

during installation and cannot fall down. Wear

the protective clothing specified for the place of

installation.

If the stuffing box is leaking there is a risk of

severe injuries caused by escaping hot fluid.

Use the equipment only if it is in proper working

condition. Replace any leaking stuffing box seal.

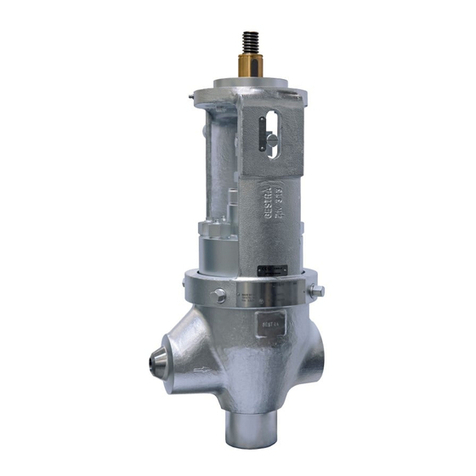

The equipment can be provided with different

types of actuator, e. g. with an electric or

pneumatic actuator. Depending on the type of

power supply for the actuator there is a risk of

severe injuries or death for various reasons.

Before working on the equipment cut off power

supply to the actuator. Observe all danger notes

and follow all instructions given in the

installation & operating manual of the actuator.

If you have a question please contact the

manufacturer of the actuator.

The moving parts of the equipment can cause

severe injuries or death. Make sure that nobody

is standing close to these moving parts or can

touch them while the equipment is operating.

Before working on the equipment make sure

that the power supply to the actuator is cut off

and cannot be switched on accidentally.