1 Table of contents

1 Safety chapter ......................................................................1

1.1 Explanation of symbols .......................................................1

1.2 Target audience of the installation instructions ................... 1

1.3 Specieduse......................................................................2

1.4 General safety information ..................................................2

2 Storage and transport .........................................................3

3 Product overview .................................................................3

3.1 Technical data .....................................................................3

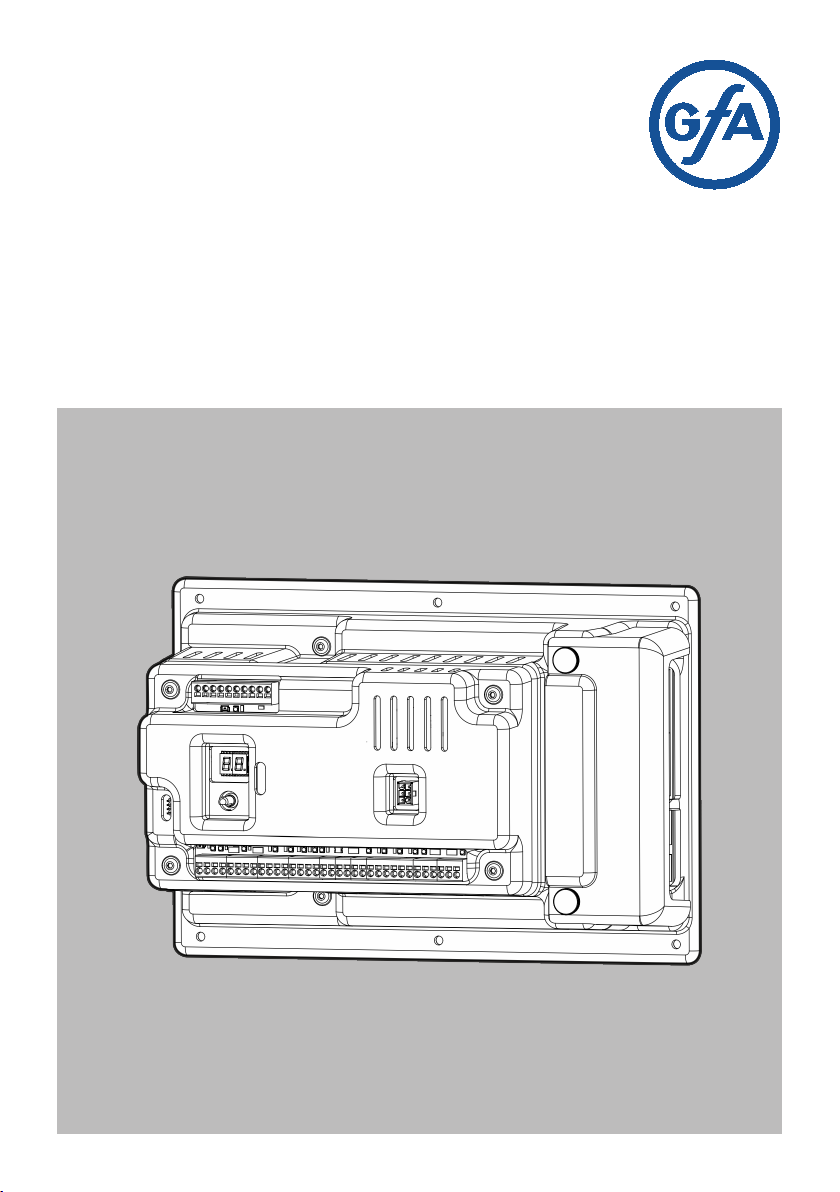

3.2 Overview of the DC 8010 ....................................................4

3.3 Overview of the control unit .................................................5

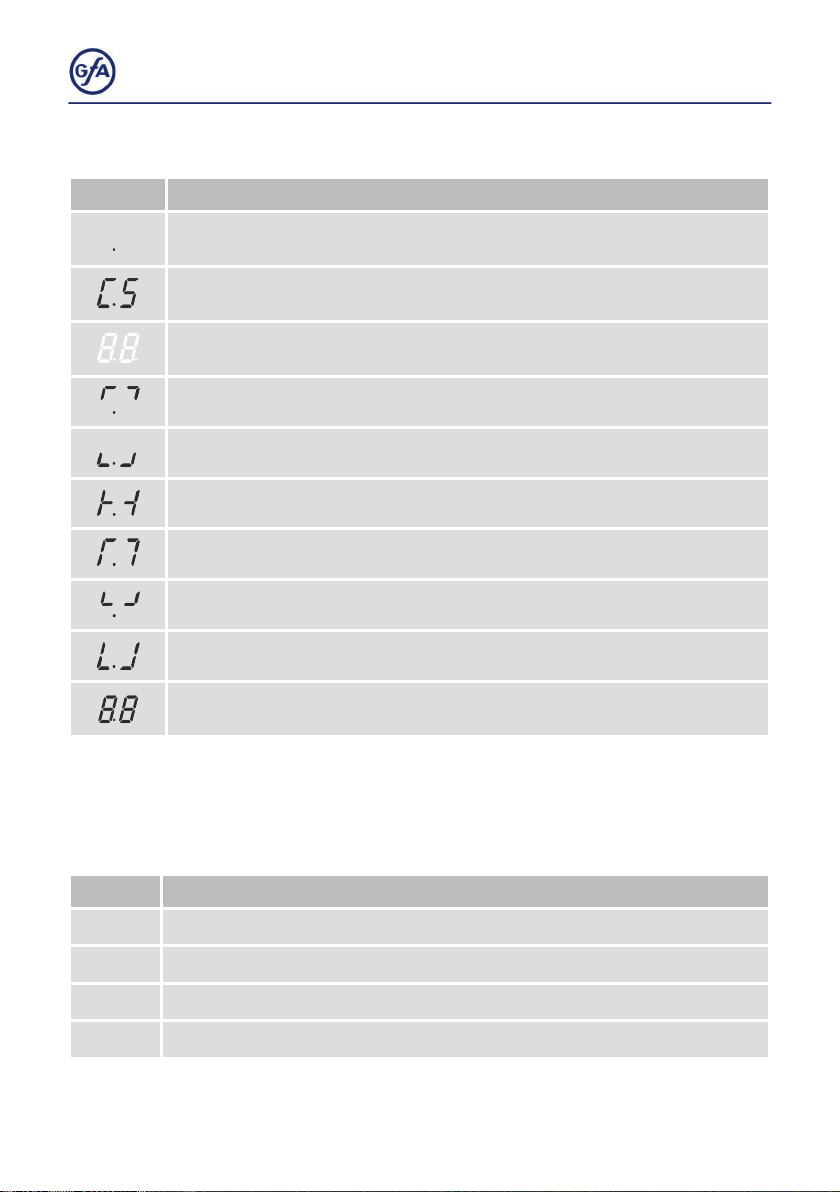

3.4 Status displays of the door control ......................................6

4 Mechanical installation .......................................................8

5 Electrical installation ...........................................................9

5.1 Fuses .................................................................................10

5.2 Connecting limit switch to the door control ........................ 10

5.3 Connecting motor to door control ...................................... 11

5.4 Motor cable conductor size (AWG) ................................... 13

5.5 Setting the operating voltage .............................................14

5.6 Connecting the door control to the power grid .................. 14

6 Connecting external devices ............................................15

X: Power supply 24V DC ...................................................16

X2: Safety edge

..................................................................16

X2: Door safety switch .......................................................19

X3: Emergency stop switch ...............................................19

X4: Switch for automatic closing ........................................20

X5: External control device ................................................21

X6: Photocell ......................................................................22

X7: Radio receiver / pull switch ..........................................23

X8: Switch for intermediate open ...................................... 24

X20/ X21: Potential-free relay contacts ............................. 24

X29: Separate control for magnetic brakes .......................25