Installation..................................................7

Care and Cleaning.......................................16

Troubleshooting........................................16

Service Parts................................................17

Table of Contents

Important Information

Important Information.................................2

Warranty

......................................................

3

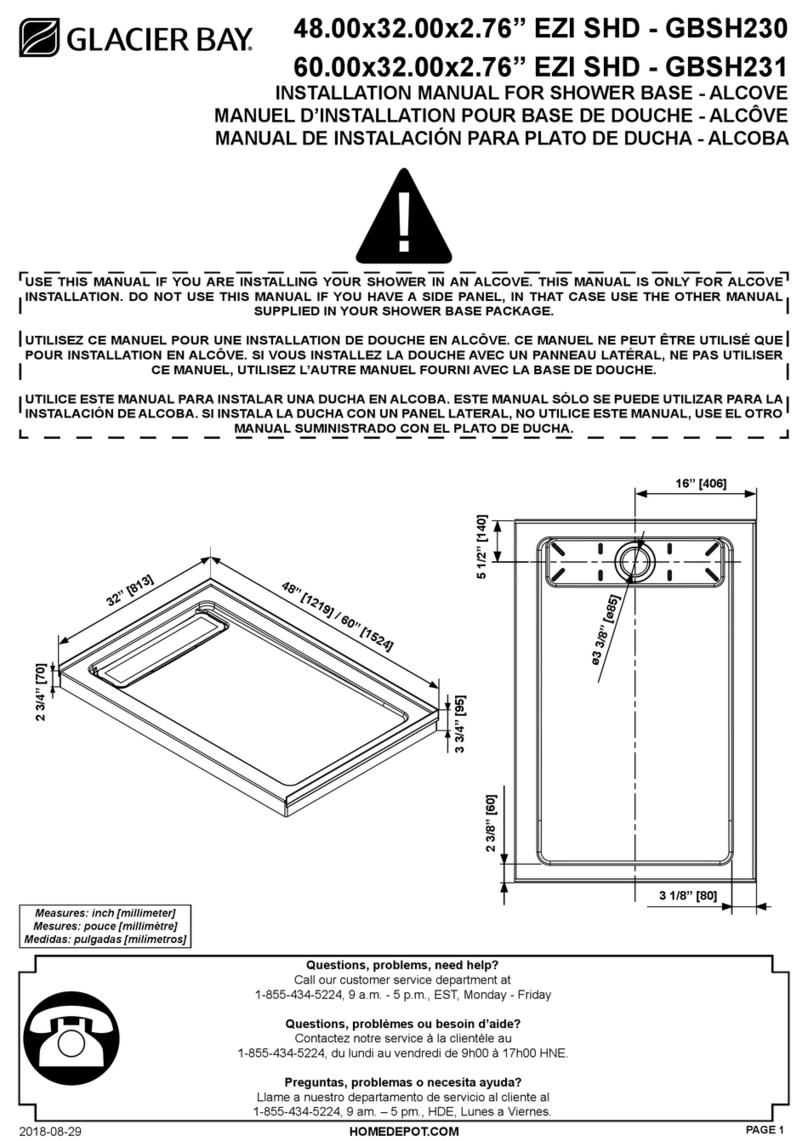

Pre-installation............................................3

Planning Installation

................................

3

Helpful Tools

............................................

3

Package Contents....................................6

Please read and understand this entire manual before attempting to assemble, operate or install the product.

NOISE AND WATER HAMMER IN PEX SYSTEMS

As with all plumbing materials under some operating conditions, water hammer can occur in PEX plumbing

systems. The inherent flexibility of PEX drastically reduces the magnitude of pressure surges compared with

metallic plumbing materials. Damage to plumbing components in a PEX system due to these pressure surges in

highly unlikely, although noise can sometimes result. Fortunately, there are solutions to minimize of eliminate

water hammer noise.

Clamping or strapping more frequently may help prevent tubing noise. It is very important that the tubing not be

in contact with wall-board, forced air ducts or other high resonance articles. Insufficiently or improperly clamped

or strapped tubing may move during fixture operation and hit against these surfaces.

Install a water hammer arrester at fixtures where noise is a problem. A water hammer arrester installed within 6

feet of the fixture on the cold water side only will eliminate the source of the noise: the pressure wave. It should

be noted that even with an arrester, tubing which is clamped or strapped insufficiently may still hit against

something as it moves slightly when the water flow is stopped.

Avoid operating fixtures in such a way that causes near instantaneous shut off. Simply closing fixtures in a less

abrupt manner can eliminate hammer noise.

CAUTION:

Inlet ports are designed to allow for 1/2 in. copper tubing solder connection or 1/2 in. IPS threading coupling

connection. For threaded connections, wrap pipe tape around threaded ends before connecting. If soldering

connections, remove plaster guard, cartridge and check valves. Connect water supply to the pipe by soldering.

Reassemble check valves, cartridge and plaster guard.

Heat damage to these parts may occur and result in the warranty being void on these parts.

• This product is engineered to meet the EPA WaterSense flow requirement. The flow rate is governed by the

aerator or flow controller. If replacement is ever required, be sure to replace it with a WaterSense compliant

aerator or flow controller to retain the water conserving flow rate of this product.

• The automatic compensating valve shall be used with shower rated at 1.3 gpm (4.9 L/min) or higher.

• The shower shall be used with automatic compensating valve rated at 1.43 gpm (5.4 L/min) or less.

• The product should be installed by a locally licensed plumber.

Contact the Customer Service Team at 1-855-434-5224 or visit www.HomeDepot.com.

2