Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

1

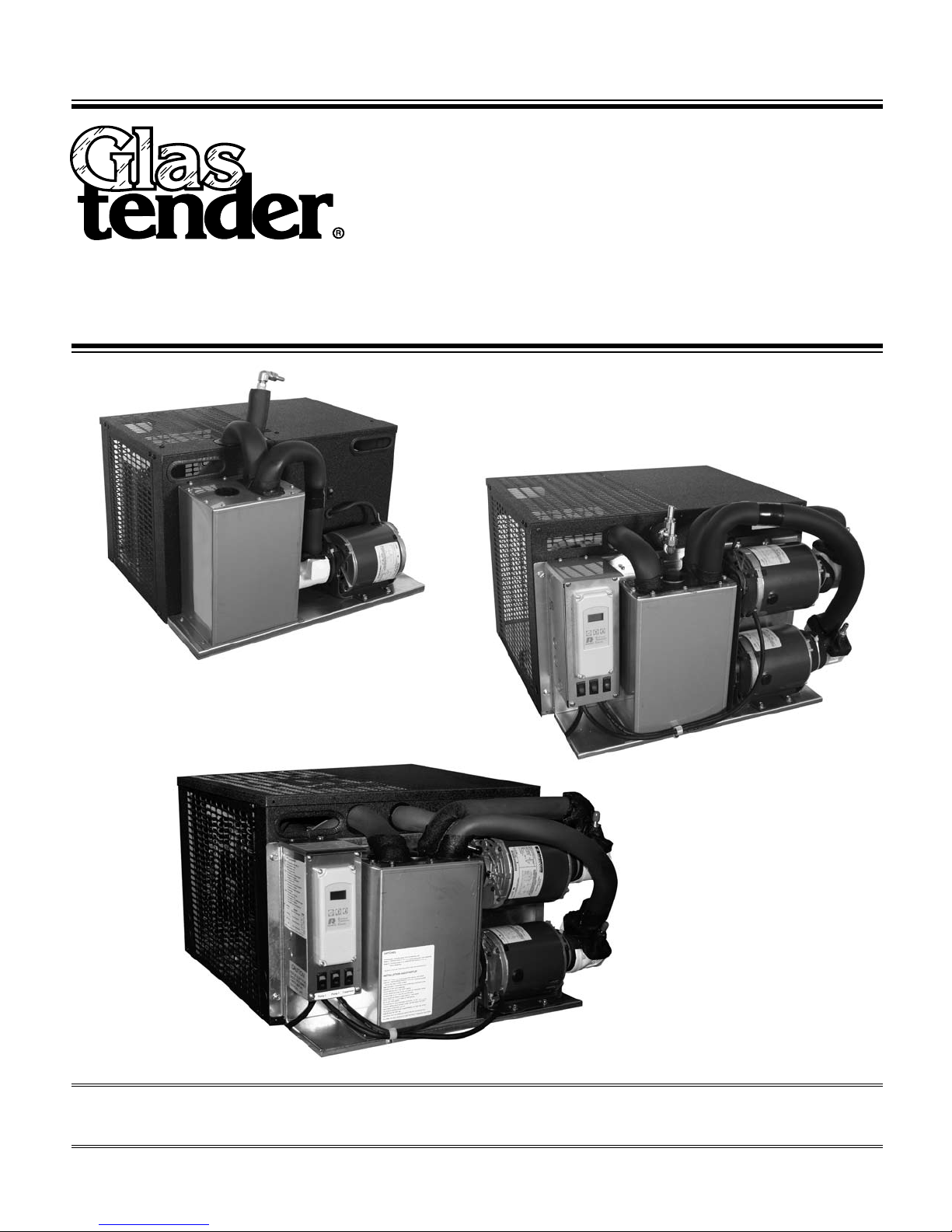

BLC speCifiCations

BLC-1/3-2

stanDaRD featuRes:

• Glycol connections with flared fittings for easy service access

• Durable black vinyl-clad exterior with 16 gauge galvanized steel base

• Stainless steel, CFC-free, foamed-in-place insulated glycol bath

• High efficiency heat exchanger minimizes glycol bath size to one gallon

• Front located glycol filling port

stanDaRD featuRes:

• Control panel is removable and includes wall bracket for remote installation

• Glycol connections with flared fittings for easy service access

• Durable black vinyl-clad exterior with 16 gauge galvanized steel base

• Stainless steel, CFC-free, foamed-in-place insulated glycol bath

• High efficiency heat exchanger minimizes glycol bath size to one gallon

• Front located glycol filling port

• Digital temperature control with LCD display

• Over-sized condenser coil for maximum efficiency

• Clear glycol bath cover for easy visual inspection

• Available with two recirculating pumps (designated by “-2” suffix in model number)

Dimensional and Specication Information

1/3 HP Beer Line Chiller Model: BLC-1/3-E

1/3, 1/2, and 3/4 HP Beer Line Chillers with Remote Installable Control Panel

Models: BLC-1/3, BLC-1/3-2, BLC-1/2, BLC-1/2-2, BLC-3/4, BLC-3/4-2

Model No. BLC-1/3-E BLC-1/3 BLC-1/3-2 BLC-1/2 BLC-1/2-2 BLC-3/4 BLC-3/4-2

Dimensions†Length 27" 27" 27" 27" 27" 27" 27"

Width 21-1/4" 25-5/8" 25-5/8" 25-5/8" 25-5/8" 25-5/8" 25-5/8"

Height 14-3/4" 16" 16" 16" 16" 16" 16"

†Note: A minimum six inch clearance should be allowed around the entire unit for proper air ow.

Additional clearance should be considered above and in front of the unit for service access.

Electrical Voltage 120V 120V 120V 120V 120V 230V 230V

Frequency

60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz

Phase 1ø 1ø 1ø 1ø 1ø 1ø 1ø

FLA 12.5 12.5 17.5 13.6 18.6 10.1 12.9

Dedicated

Circuit

20A 20A 30A 20A 30A 20A 20A

Electrical

Connection

Cord & Plug Cord & Plug

Hard Wire

Cord & Plug

Hard Wire Cord & Plug Cord & Plug

Refrigerant R134a R134a R134a R134a R134a R134A R134A

Compressor 1/3 HP 1/3 HP 1/3 HP 1/2 HP 1/2 HP 3/4 HP 3/4 HP

Max Distance to Taps 125 ft. 125 ft. 125 ft. 250 ft. 250 ft. 400 ft. 400 ft.

Circulating Pumps 60 gph 60 gph 60 gph 60 gph 60 gph 60 gph 60 gph

Glycol Bath Capacity .94 gal .94 gal .94 gal .94 gal .94 gal .94 gal .94 gal.

Shipping Weight LBS (kg) 128 (58.1) 150 (68.0) 163 (73.9) 153 (69.4) 166 (75.3) 175 (79.5) 193 (87.7)

BLC-1/3-E