Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com 6

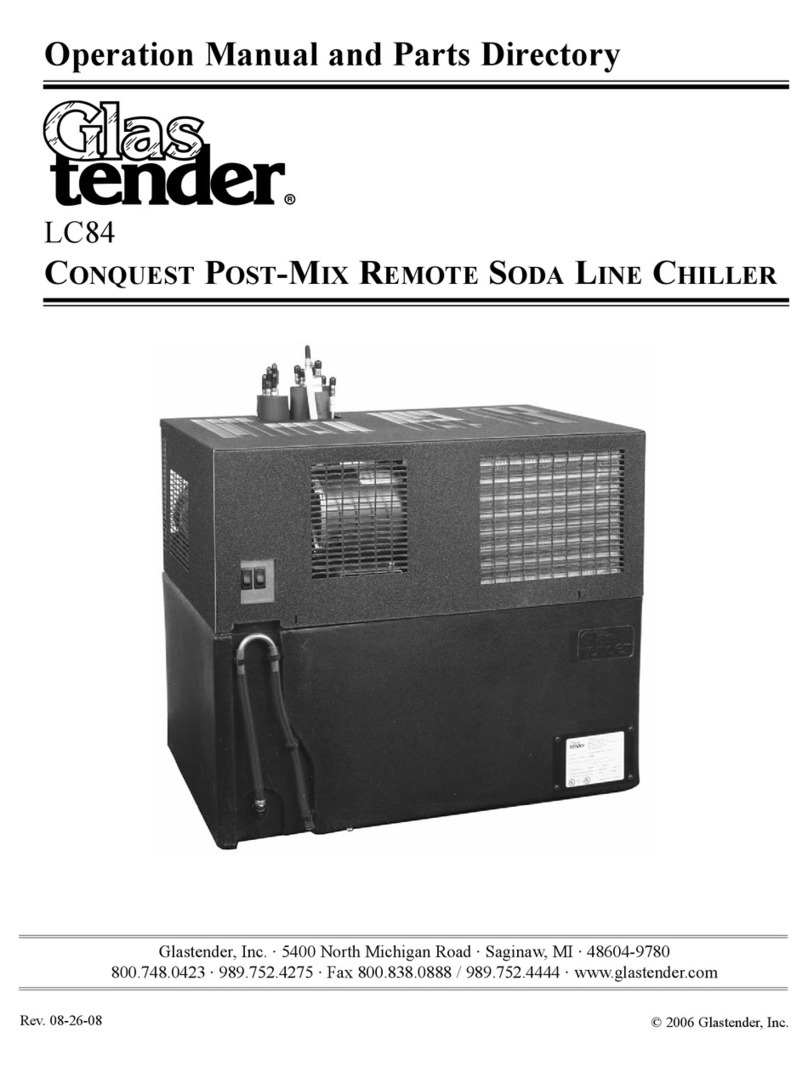

ProDuct information

Glastender, Inc.’s remote glycol line chillers are self-contained. Self-contained units have the compressor/

condensing unit mounted on the equipment and connected at the factory.

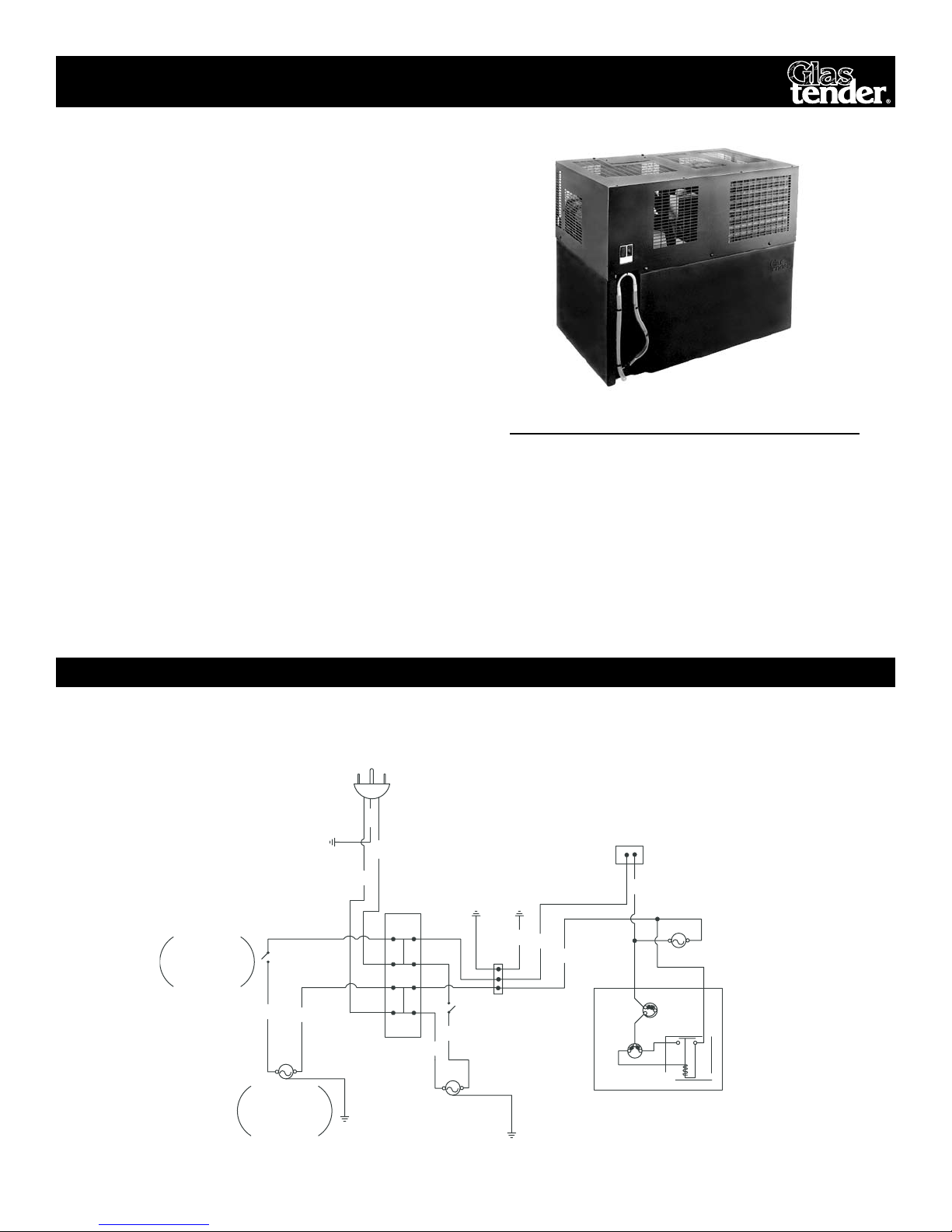

installation anD start-uP

The selling dealer is responsible for installation and start-up. Glastender, Inc. is not responsible for any instal-

lation or start-up costs.

A. An “installation decal” with suggested guidelines is placed on each piece of equipment. Installation instruc-

tions are also found in the operation manual.

B. Remote glycol line chillers contain component parts that must be checked or adjusted at the time of installa-

tion. These components include: thermostats, hardware, recirculating pumps, pressure controls, refrigerant

charge, etc.

C. Installation must comply with local plumbing, refrigeration, and electrical practices/codes.

service resPonsibilities

The end user and/or dealer are responsible for securing a local refrigeration service company. Glastender, Inc. will

provide technical support and spare parts to that selected company.

If an end user does not have a favorite service company, the factory can usually recommend one. A directory of

Service Agents is published annually and is available upon request.

Warranty information

A. Glastender, Inc. warrants all products to be free of defects in material and workmanship. Within one year

from date of installation, or 15 months from date of factory shipment, whichever occurs sooner, Glastender,

Inc. will replace any part or assembly found defective under normal use and service. Field replacement parts

include a warranty of 90 days from date of installation.

B. This warranty is conditioned upon Glastender, Inc. receiving notice of any defect subject to this warranty

within sixty (60) days of its discovery by the end user or dealer.

C. This warranty does not apply to damage resulting from fire, water, burglary, accident, abuse, misuse, acts of

God, attempted repairs, or improper installation by unauthorized persons.

D. Glastender, Inc. shall not be liable for loss of use, revenue, or profit or for any other indirect, incidental, special,

or consequential damage including, but not limited to product spoilage or loss. No representative, distributor,

dealer, service company, or any other person is authorized to modify this warranty. This warranty replaces all

other written or verbal warranties.

E. Glastender, Inc. requires proof of the installation date and may delay payment for claims until adequate proof is

provided.

F. The following are considered “in-warranty”:

1. Exchange of defective parts within one year from date of original installation or 15 months from date of fac-

tory shipment.

2. Compressors exchanged within the five-year compressor warranty period, which begins on the date the

equipment was manufactured.

remote Glycol line chiller Warranty information