USER MANUAL

Range BEAT-Tr

Edition: January 2016

Revision: No. 3 GENERAL INDEX - 3

CONTENTS:

Page:

CHAPTER 1: INTRODUCTION............................................................................ 5

1.1 General.................................................................... 5

1.2 Design Specifications................................................. 6

1.3 General Information.................................................. 6

1.4 Unit Identification...................................................... 7

1.4.1 Serial number stamping............................................. 7

1.4.2 CE making................................................................ 7

1.5 Measures of protection against accidents...................... 8

1.5.1 Safety alert symbols........................................ 8

1.5.2 Safety measures and dangers........................... 8

1.6 Declaration “CE” of conformity.................................... 10

1.7 Guarantee................................................................ 11

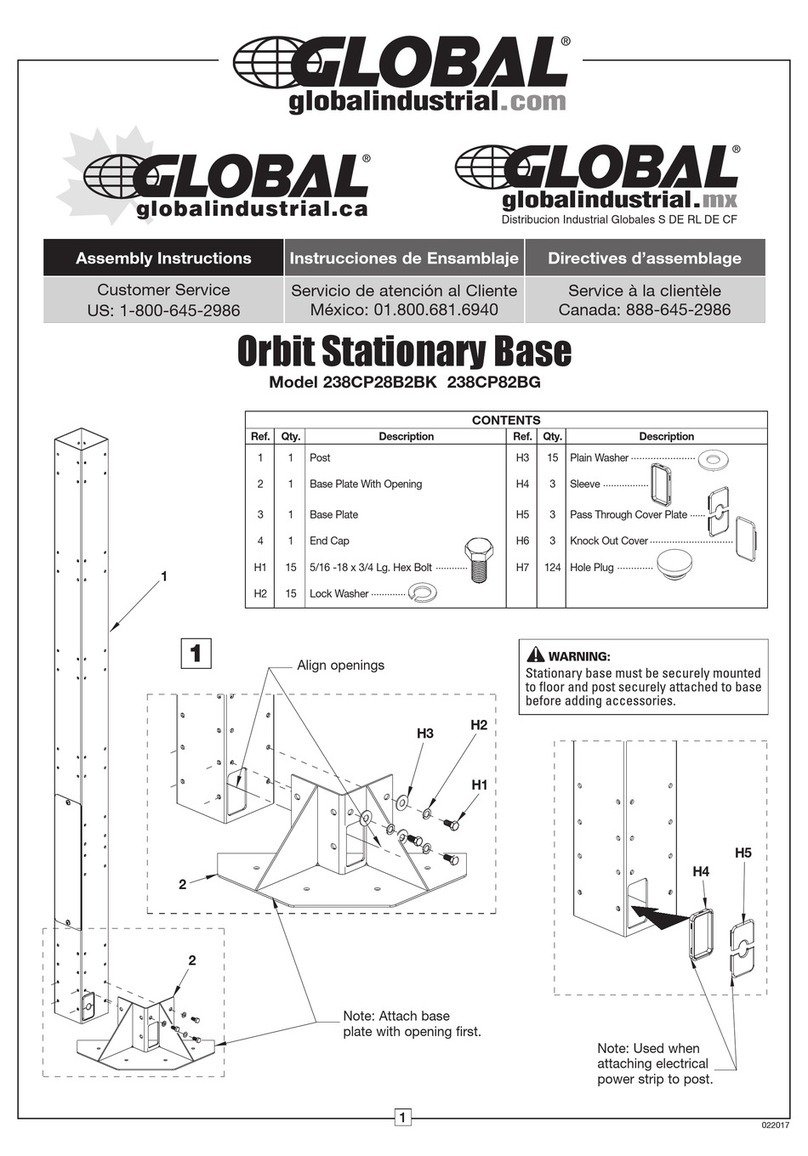

CHAPTER 2: DESCRIPTION OF THE ELECTROFUSION UNIT................................... 12

2.1 General.................................................................... 12

2.2 Front....................................................................... 13

2.3 Right and left sides.................................................... 13

2.4 Top and rear sides..................................................... 14

CHAPTER 3: MODE OF USE............................................................................... 15

3.1 Electrofusion procedure.............................................. 15

3.1.1 Introduction............................................................. 15

3.1.2 Scraping pipe surfaces............................................... 15

3.1.3 Fitting installation..................................................... 15

3.1.4 Unit connection......................................................... 16

3.1.5 Using the Barcode reader........................................... 18

3.1.6 Entering the operator number..................................... 19

3.1.7 Entering the job number............................................ 20

3.1.8 Entering auxiliary data............................................... 21

3.1.9 Traceability.............................................................. 22

3.1.10 Fitting connection...................................................... 24

3.1.11 Entering electrofusion data in the unit......................... 24

3.1.12 Electrofusion process................................................. 27

3.1.13 Cooling time............................................................. 28

3.2 Access to other menus............................................... 29

3.2.1 Available options....................................................... 29

3.2.2 FUSION RECORDS option........................................... 29

3.2.3 INFO option.............................................................. 36

3.2.4 SETUP option............................................................ 37

3.2.5 LAST REVISION option............................................... 42

3.2.6 SERVICE option......................................................... 42