1)

The wound bobbin thread should be neat and tight,

if

not, adjust the winding tension by turning

Tension Stt!d Nut

(A)

of

bobbin winder tension bracket.

Note: nylon

or

polyester thread should

be

wound with little tension, otherwise, Bobbin ( D ) might.break

or deform.

2) When the wound thread layer does not present a cylindrical shape

as

shown in Fig.8 (

a)

, loosen Set

Screw ( B )

of

bobbin winder tension bracket and slide Bracket ( C ) leftward or rightward.

If

thread

is

wound

as

shown

in

Fig.8 ( b ), move the bracket rightward, but

if

thread

is

wound as shown in Fig.8 ( c ), move the

bracket leftward.

After adequately positioning the bracket, tighten Set Screw ( B

).

3) Do not overfill the bobbin.

The

optimum length

of

thread will fill about 80%

of

bobbin capacity. This can be

adjusted by Adjusting Screw (

E)

of

bobbin winder stop latch.

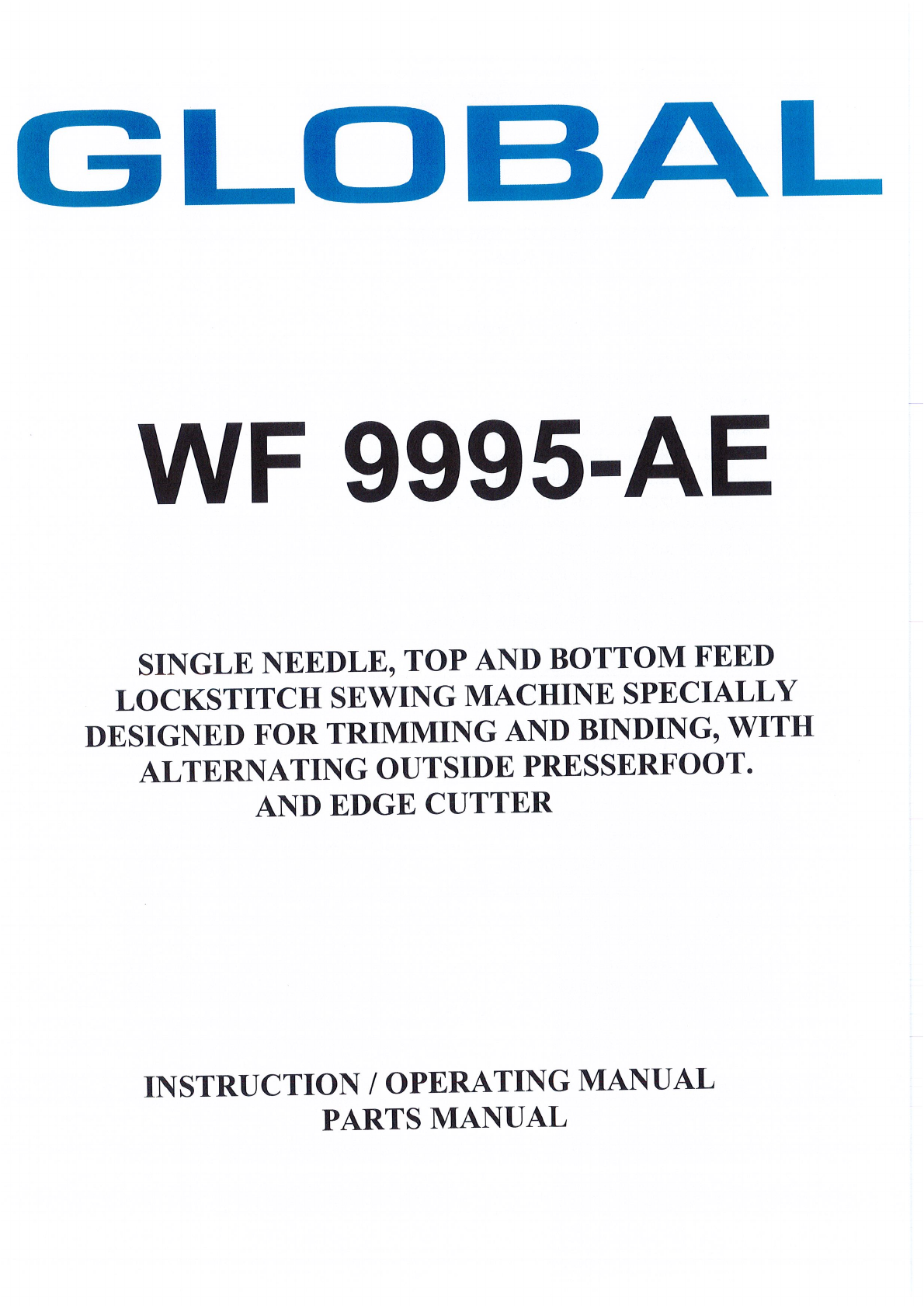

10.POSITION PRESSER BAR (

Fig.9)

1)

Loosen lock

Nut

(

E)

and Pressure Regulating Thumb Screw

(A).

2) Remove rubber plug from Face Plate ( B

).

3) Loosen Screw (

C)

and adjust the position

of

Presser

Bar

(

D)

till the presser foot

is

6 mm above the

throat plate will the presser foot lifted to its highest.

4) Tighten Screw (

C)

and put

in

the rubber plug.

5) Tighten pressure Regulating Thumb Screw

(A)

and Lock Nut ( E

).

a b

Fig.9 Fig.

10

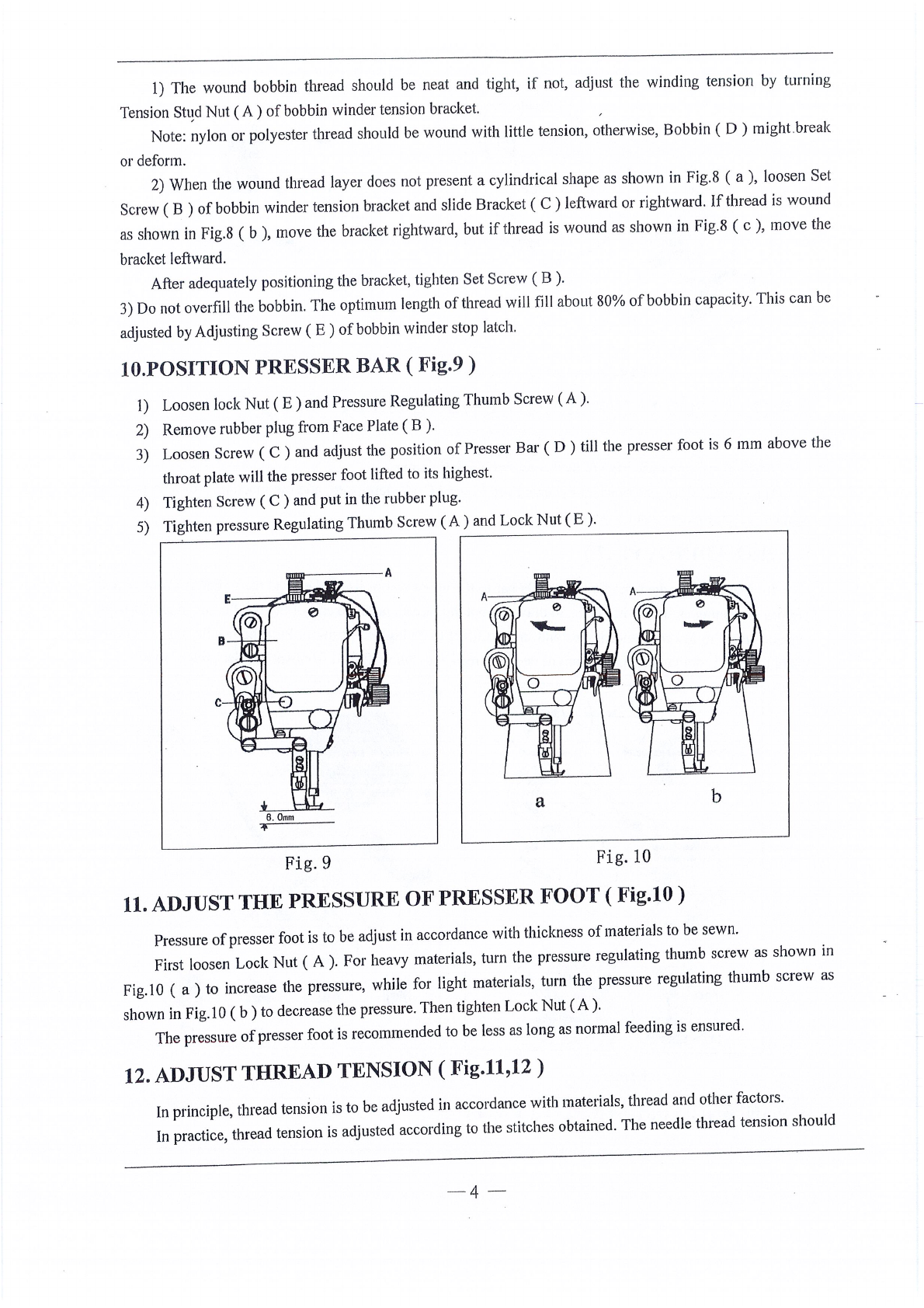

11.

ADJUST THE PRESSURE OF PRESSER FOOT (

Fig.10)

Pressure

of

presser foot is to be adjust

in

accordance with thickness

of

materials to be sewn.

First loosen Lock Nut ( A

).

For heavy materials, turn the pressure regulating thumb screw as shown

in

Fig.

IO

( a ) to increase the pressure, while for light materials, turn the pressure regulating thumb screw as

shown in Fig.

IO

(

b)

to decrease the pressure. Then tighten Lock Nut

(A).

The pressure

of

presser foot is recommended to be less

as

long as normal feeding

is

ensured.

12. ADJUST THREAD TENSION ( Fig.11,12 )

In

principle, thread tension

is

to be adjusted

in

accordance with materials, thread and other factors.

In

practice, thread tension is adjusted according to the stitches obtained. The needle thread tension should

-4

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com