APRIL 2019 GFS-350 PAGE 3 of 4

CARE AND MAINTENANCEINSTALLATION

Step 1. Install pendent sprinklers in the pendent

position, with the centerline of the sprinkler

perpendicular to the mounting surface.

Step 2. Remove the Protective Cap.

Step 3. With pipe-thread sealant applied to the pipe

threads, and using the Concealed Sprinkler

Wrench P/N 325391 (FIGURE 2), install and

tighten the Sprinkler/Concealed Cup Assembly

into the tting.

Step 4. Replace the Protective Cap by pushing it

upwards until it bottoms out against the Sup-

port Cup. The Protective Cap helps prevent

damage to the Deector and Drop Pins during

ceiling installation and/or during application of

the nish coating of the ceiling.

NOTICE:

The system is considered Out of Service when

the protective caps are in place.

Step 5. After the ceiling has been completed with the

2-1/2” (63.2mm) diameter hole, remove and

discard the Protective Cap and verify that the

Deector moves up and down freely. If the

sprinkler has been damaged or the deector

does not move up and down freely, replace

the entire sprinkler assembly. Do not attempt

to modify or repair.

Step 6. Push on the Cover Plate Assembly until its

ange contacts the ceiling. Never attempt to

screw on the Cover Plate Assembly such that

it lifts a ceiling panel out of its normal posi-

tion. If the Cover Plate Assembly cannot be

engaged with the Mounting Cup or the Cover

Plate Assembly cannot be engaged sufcient-

ly to contact the ceiling, the Sprinkler Fitting

must be repositioned.

Always obtain permission from the proper authorities to

shut down the affected re protection system and notify all

personnel who may be affected by this action before closing

a re protection system main control valve for maintenance

work on the system that it controls. Sprinklers should only

be cleaned by means of gently dusting with a feather dust-

er; otherwise, non-operation in the event of a re or inadver-

tent operation may result.

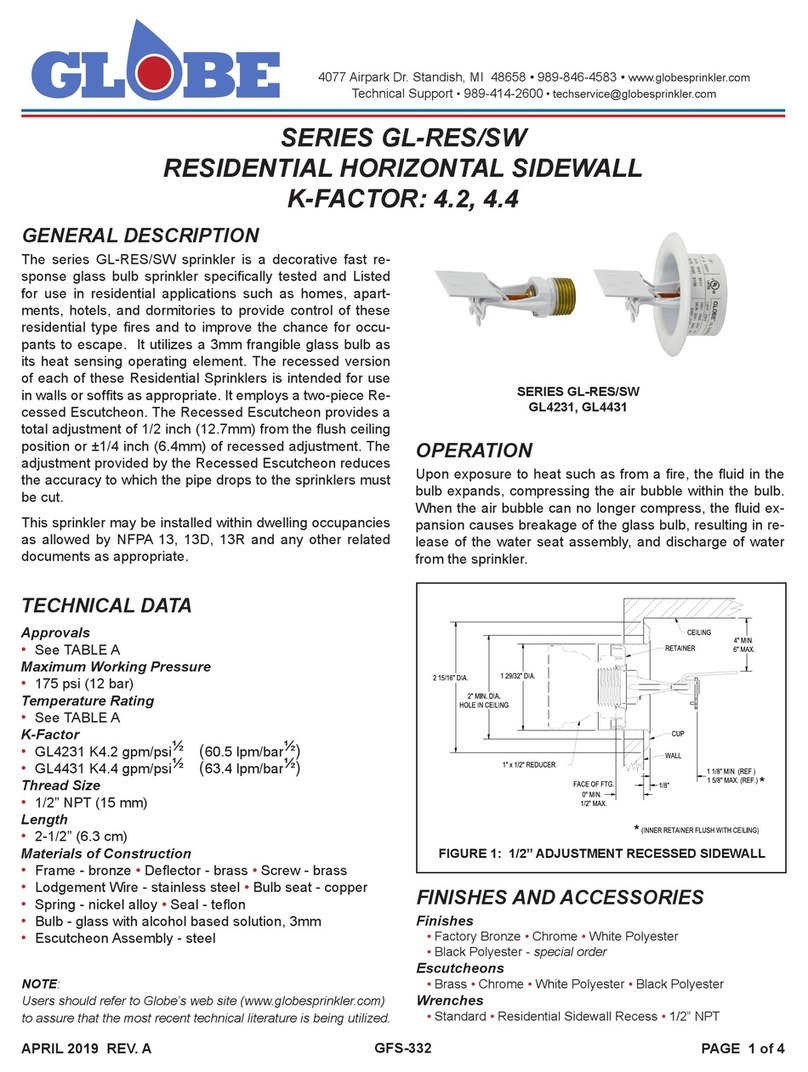

When properly installed, there is a nominal 1/8” (3mm) air

gap between the Cover Plate and the ceiling (Figure 1). This

air gap is necessary for proper operation of the sprinkler by

allowing heat ow from a re to pass below and above the

Cover Plate to help assure appropriate release of the Cover

Plate in a re situation. This annular “gap” must be main-

tained and should never be sealed or caulked.

Factory painted Cover Plates must not be repainted.

In accordance with NFPA 25, Sprinklers which are found to

be leaking or exhibiting visible signs of corrosion must be

replaced.

Automatic sprinklers must never be painted, plated, coated,

or otherwise altered after leaving the factory.

Care must be exercised to avoid damage to the sprinklers–

before, during, and after installation. Sprinklers damaged

by dropping, striking, wrench slippage, or similar incidents,

must be replaced.

The owner is responsible for the inspection, testing, and

maintenance of their re protection system and devices in

compliance with this document, as well as with the appli-

cable standards of the National Fire Protection Association

(e.g. NFPA 25), in addition to the standards of any other

authorities having jurisdiction.

Refer to Globe’s Residential Installation Guide for further

Care and Maintenance information.

TABLE B: ESCUTCHEONS

DOMED COVER PLATE

SIZE

WHITE 135°F (57°C)

P/N

CHROME 135°F (57°C)

P/N

BLACK 135°F (57°C)

P/N

CUSTOM 135°F (57°C)

P/N

3-5/16” DIA.326048 326046 326048-B 326049

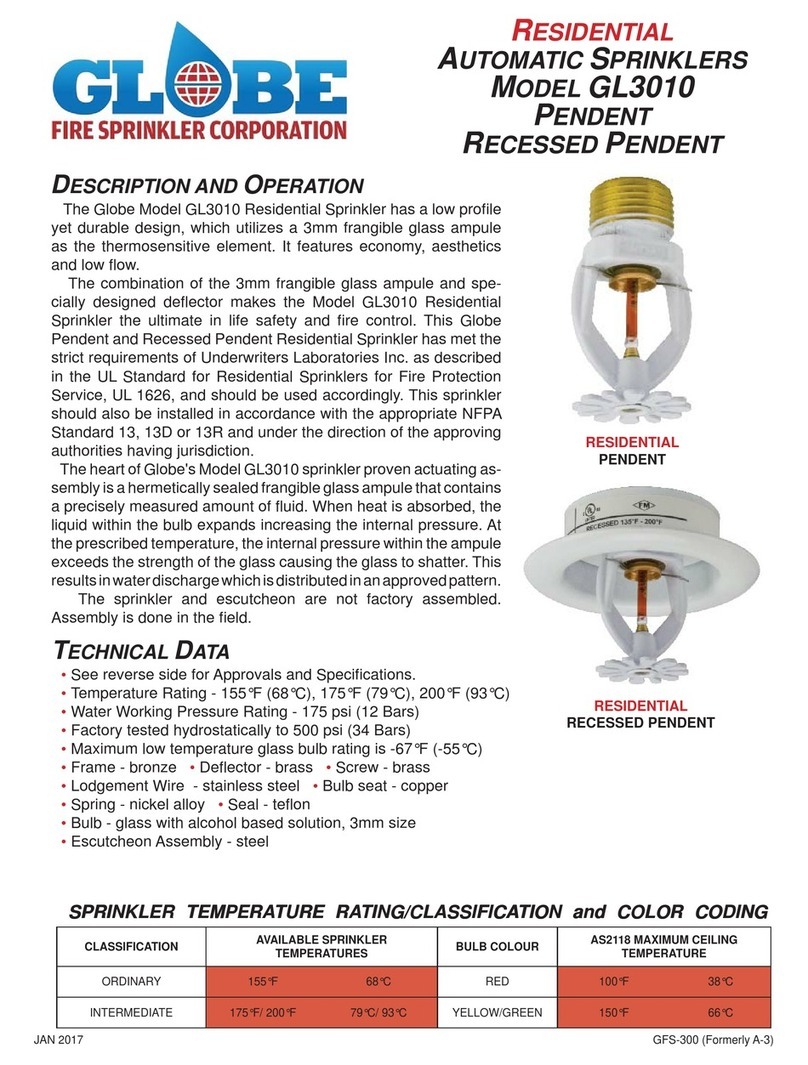

FIGURE 2: CONCEALED WRENCH

P/N 325391

NOTICE

Do not install any bulb-type sprinkler if the bulb is cracked or

there is loss of liquid from the bulb. Sprinklers should be tightened

enough to obtain a leak-tight joint when water pressure is applied

and/or hydrostatic test is performed. Sprinklers should not be

overtightened as this can result in distortion and subsequent leak-

age. It is recommended not to exceed 14 ft.-lb. (19.0 Nm) torque

for 1/2 inch NPT sprinkler threads.