APRIL 2019 REV.A GFS-302 PAGE 1 of 4

SERIES GL-RES

RESIDENTIAL PENDENT AND RECESSED PENDENT

K-FACTOR: 3.0, 4.1, 4.9, 5.6

4077 Airpark Dr. Standish, MI 48658 • 989-846-4583 • www.globesprinkler.com

Technical Support •989-414-2600 •techservice@globesprinkler.com

NOTE:

Users should refer to Globe’s web site (www.globesprinkler.com)

to assure that the most recent technical literature is being utilized.

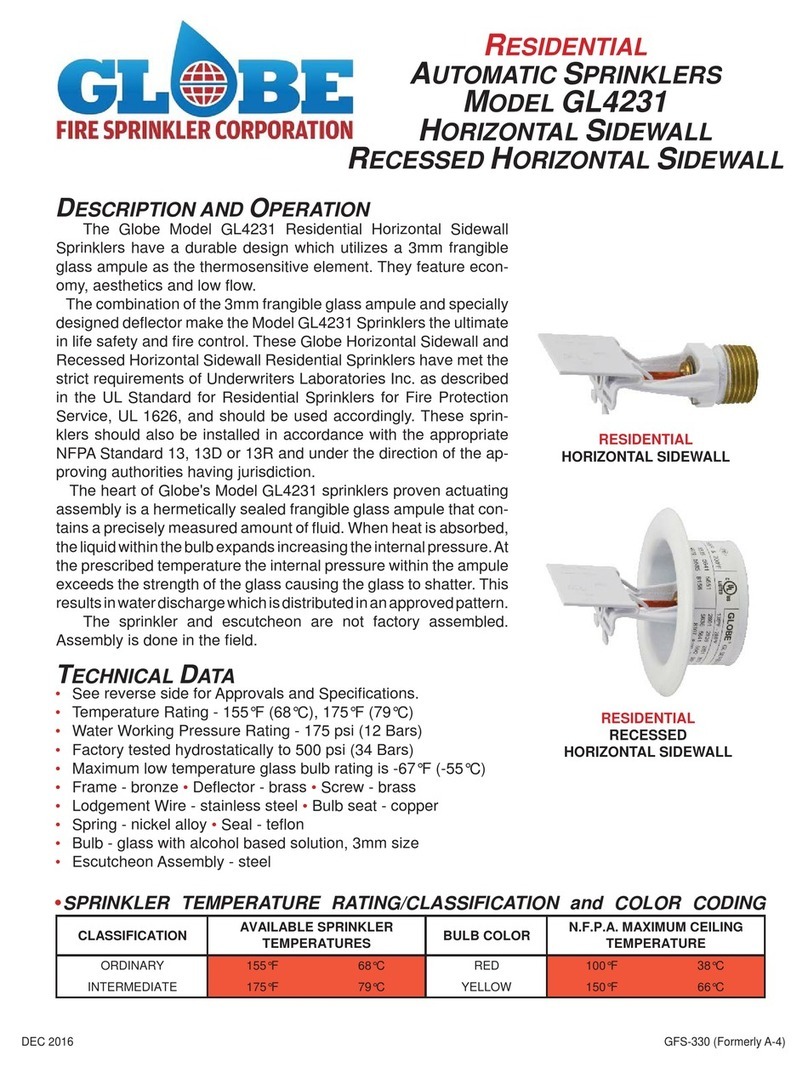

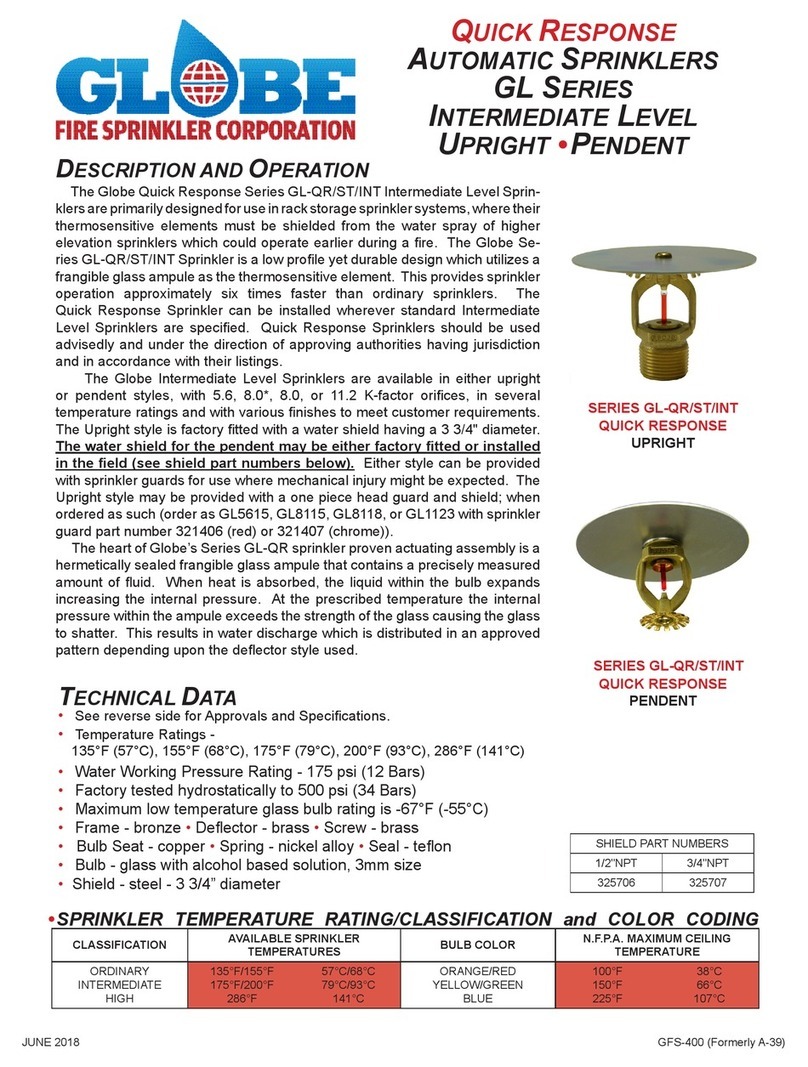

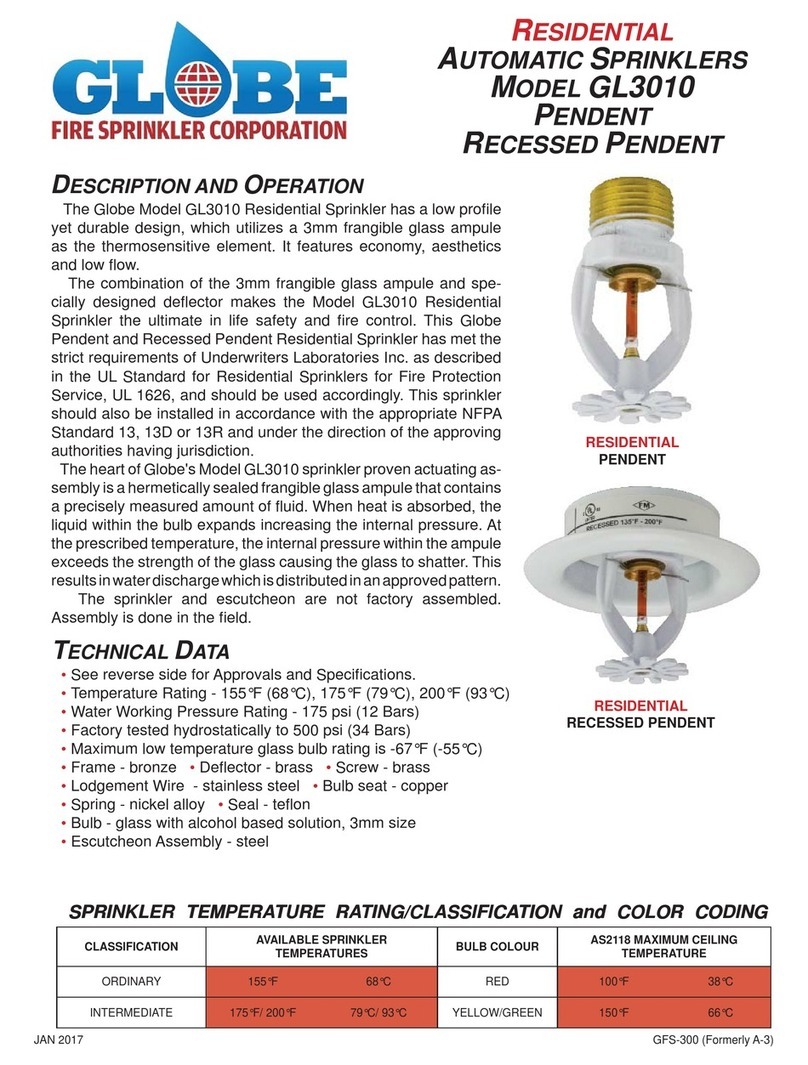

GENERAL DESCRIPTION

The series GL-RES pendent sprinklers are decorative fast

response glass bulb sprinklers specically tested and List-

ed for use in residential applications such as homes, apart-

ments, hotels, and dormitories to provide control of these

residential type res and to improve the chance for occu-

pants to escape. They utilize a 3mm frangible glass bulb as

its heat sensing operating element. The recessed version

of each of these Residential Sprinklers is intended for use

in areas with nished ceilings. It employs a two-piece Re-

cessed Escutcheon. The Recessed Escutcheon provides a

total adjustment of 1/2 inch (12.7mm) from the ush ceiling

position or ±1/4 inch (6.4mm) of recessed adjustment. The

adjustment provided by the Recessed Escutcheon reduces

the accuracy to which the pipe drops to the sprinklers must

be cut.

This sprinkler may be installed within dwelling occupancies

as allowed by NFPA 13, 13D, 13R and any other related

documents as appropriate.

The GL3010 is typically utilized when maximum coverag-

es are not needed, thereby reducing ow demands. The

GL5610 is typically the sprinkler of choice when utilizing

Residential Sprinklers within an NFPA 13 Occupancy. The

larger K-factor can be advantageous when needed to con-

form to the NFPA 13 hydraulic Special Design Approach for

Residential Sprinklers.

OPERATION

Upon exposure to heat such as from a re, the uid in the

bulb expands, compressing the air bubble within the bulb.

When the air bubble can no longer compress, the uid ex-

pansion causes breakage of the glass bulb, resulting in re-

lease of the water seat assembly, and discharge of water

from the sprinkler.

TECHNICAL DATA

Approvals

• See TABLE A

Maximum Working Pressure

• 175 psi (12 bar)

Temperature Rating

• See TABLE A

K-Factor

• GL3010 K3.0 gpm/psi½ (43.2 lpm/bar½)

• GL4110 K4.1 gpm/psi½ (59.0 lpm/bar½)

• GL4910 K4.9 gpm/psi½ (70.6 lpm/bar½)

• GL5610 K5.6 gpm/psi½ (80.6 lpm/bar½)

Thread Size

• 1/2” NPT (15 mm)

Length

• 2-1/2” (6.3 cm)

Materials of Construction

• Frame - bronze • Deector - brass •Screw - brass

• Lodgement Wire (GL5610 only) - stainless steel •Bulb

seat - copper

• Spring - nickel alloy • Seal - teon

• Bulb - glass with alcohol based solution, 3mm

• Escutcheon Assembly - carbon steel

FINISHES AND ACCESSORIES

Finishes

• Factory Bronze • Chrome • White Polyester

• Black Polyester - special order

Escutcheons

•Brass • Chrome • White Polyester • Black Polyester

Wrenches

• Standard • Recess • 1/2” NPT

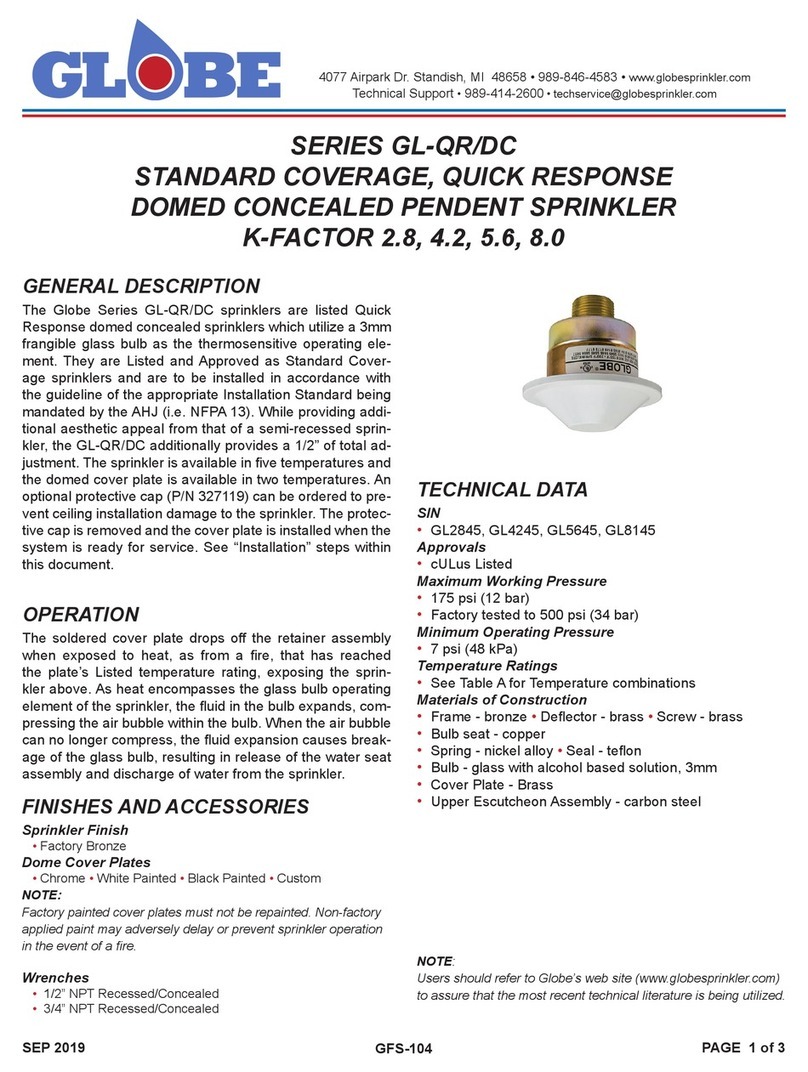

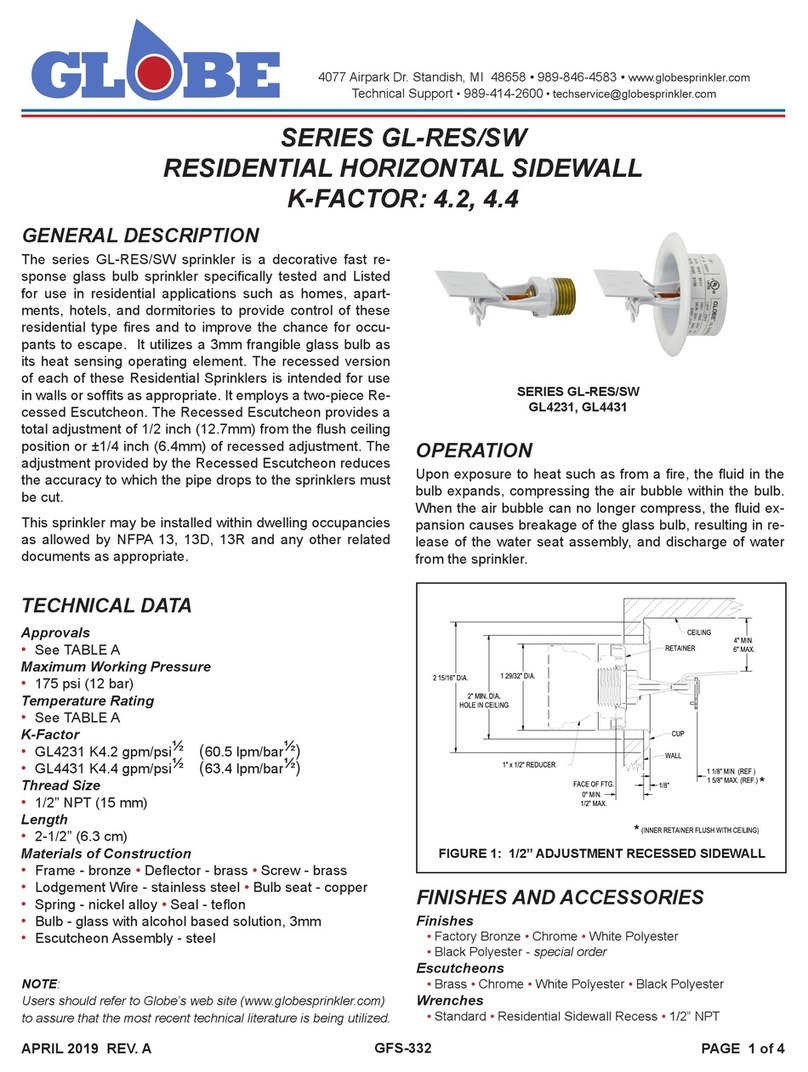

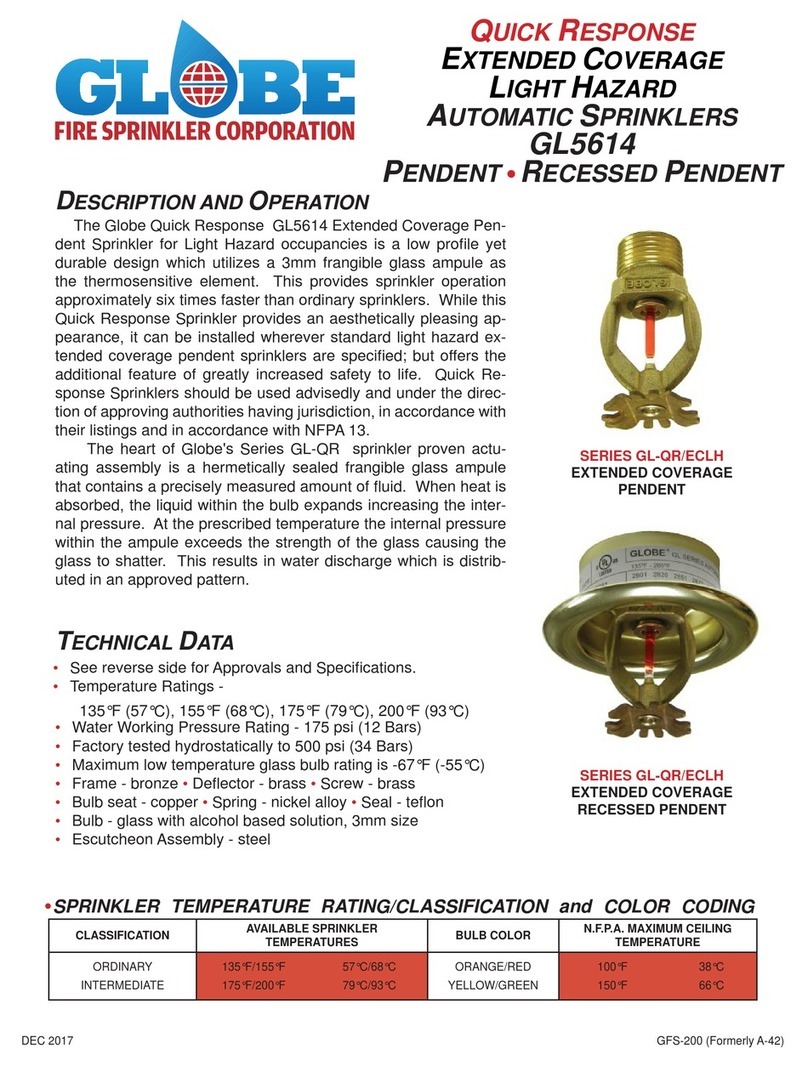

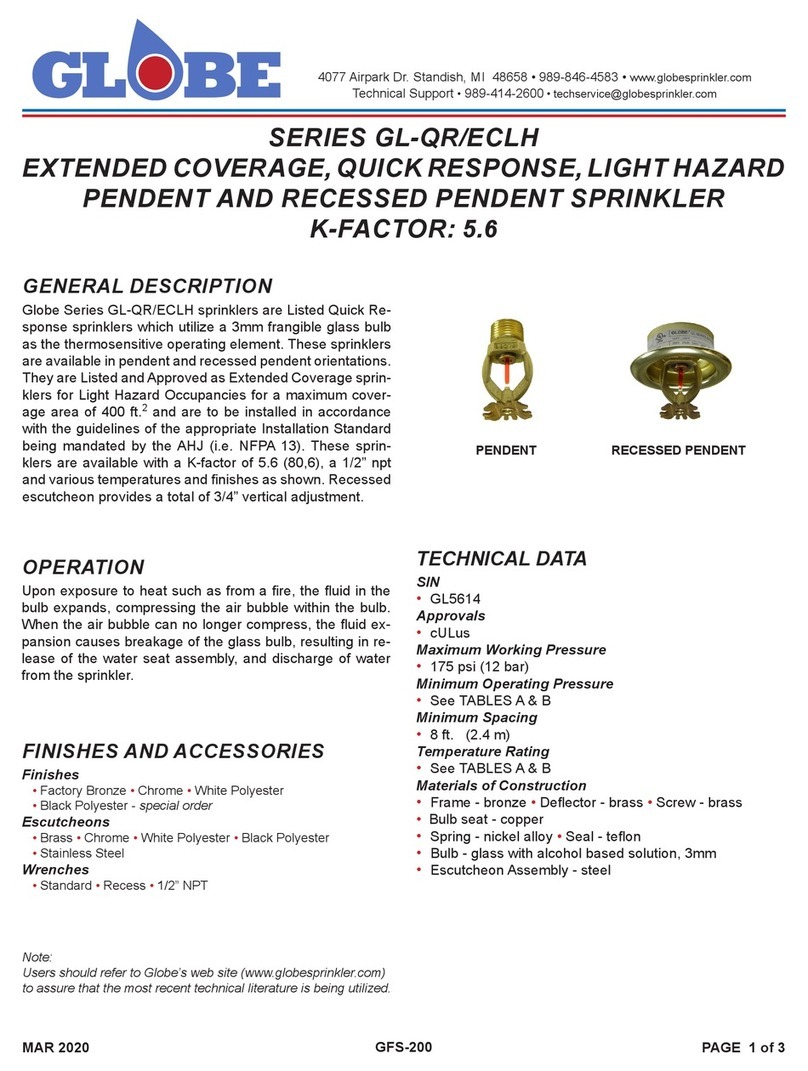

SERIES GL-RES

GL3010, GL4110, GL4910, GL5610

SERIES GL-RES RESIDENTIAL PENDENT AND RECESSED PENDENT

K-FACTOR: 3.0, 4.1, 4.9, 5.6

SERIES GL-RES RESIDENTIAL PENDENT AND RECESSED PENDENT

K-FACTOR: 3.0, 4.1, 4.9, 5.6

GFS-302 GFS-302