MAR 2020 GFS-210 PAGE 1 of 3

SERIES GL-QR/INCH/ECLH

EXTENDED COVERAGE, QUICK RESPONSE, LIGHT HAZARD

CONCEALED PENDENT SPRINKLERS

K-FACTOR: 5.6

4077 Airpark Dr. Standish, MI 48658 • 989-846-4583 • www.globesprinkler.com

Technical Support •989-414-2600 •techservice@globesprinkler.com

Note:

Users should refer to Globe’s web site (www.globesprinkler.com)

to assure that the most recent technical literature is being utilized.

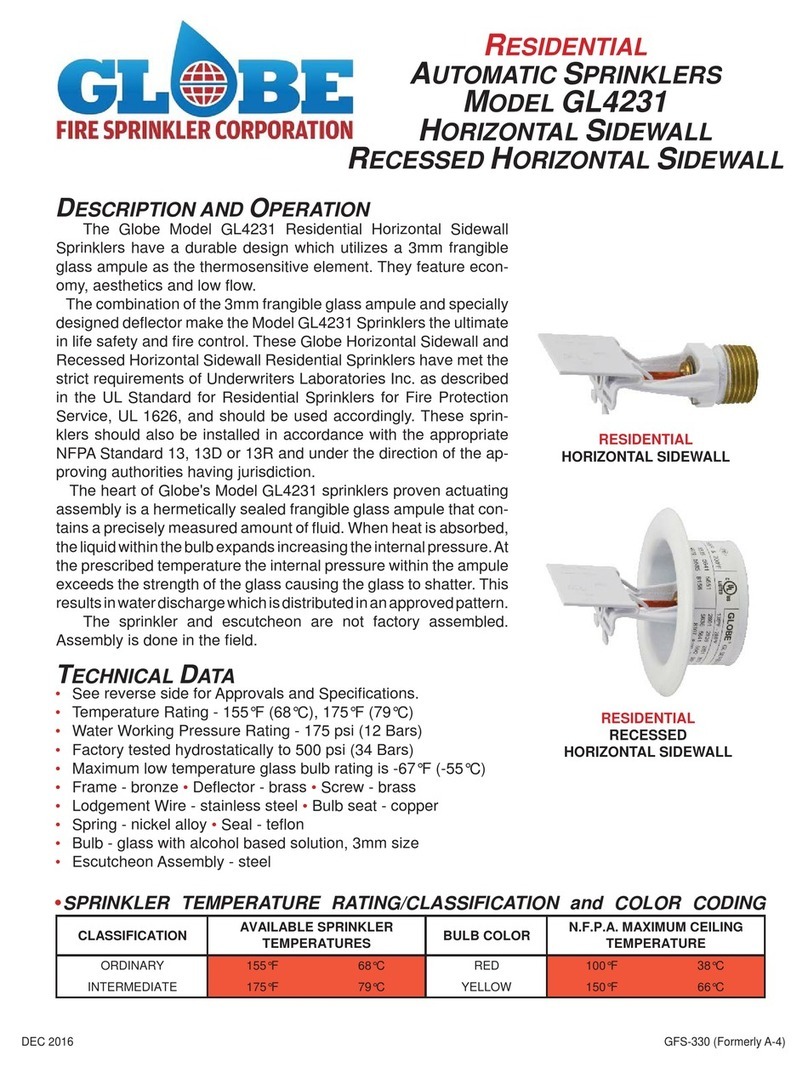

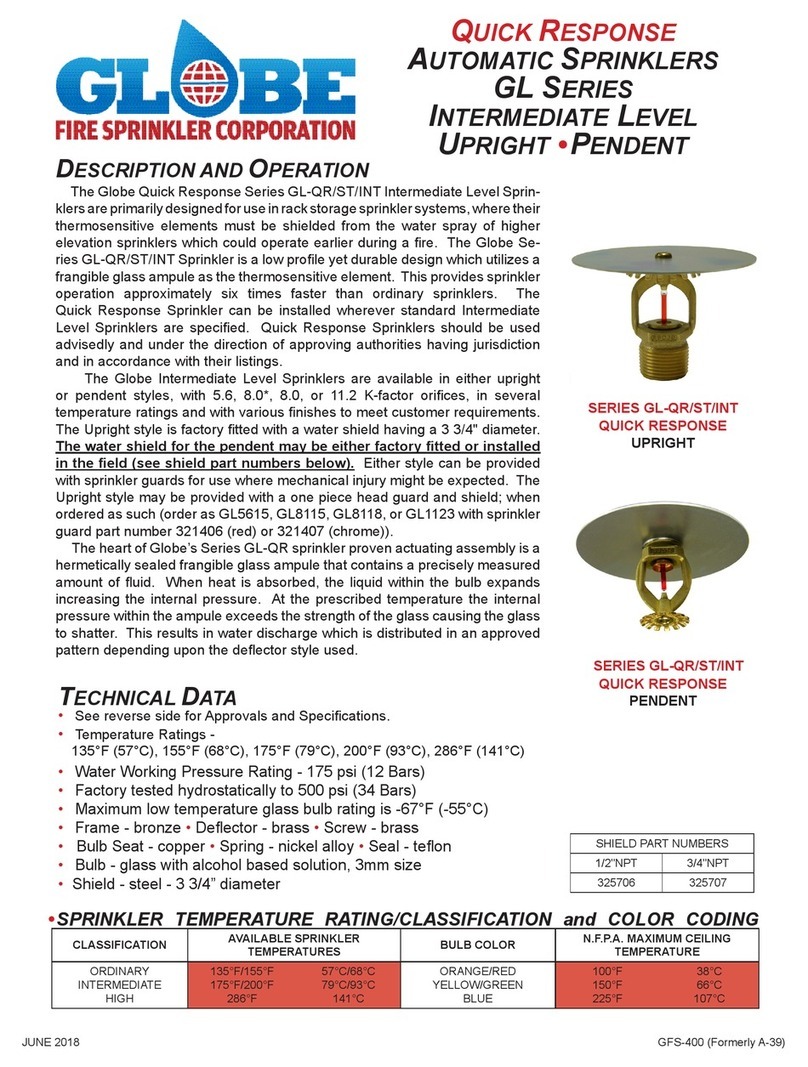

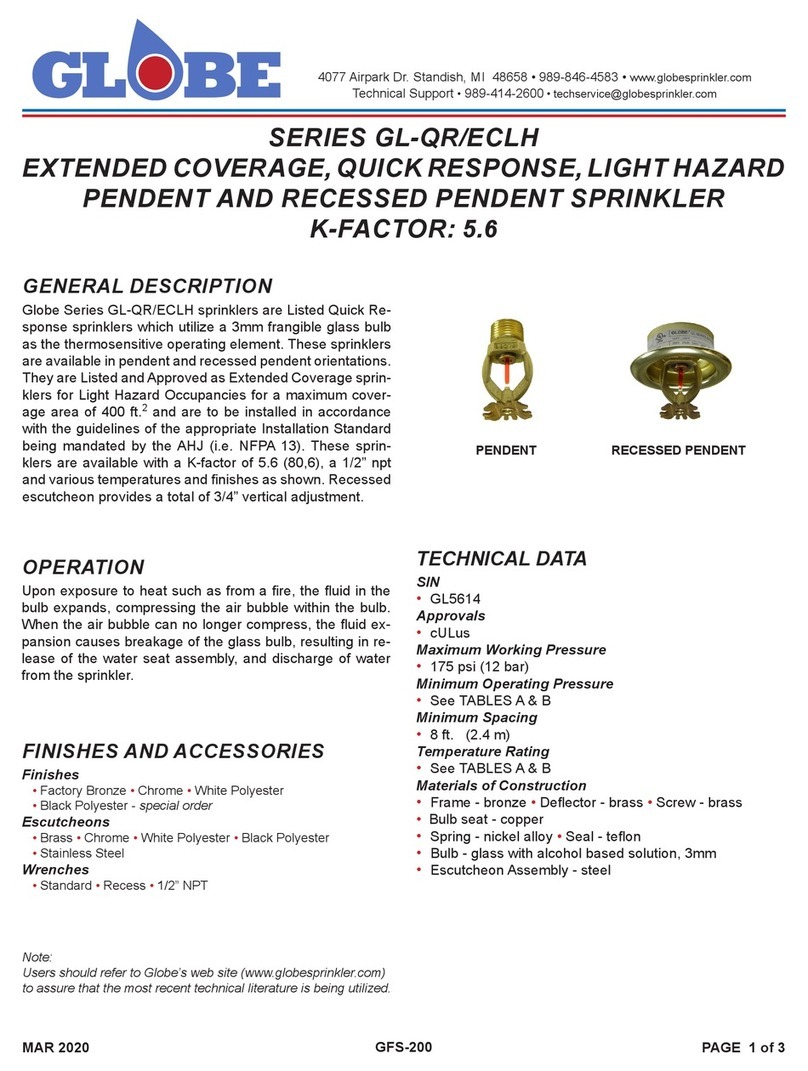

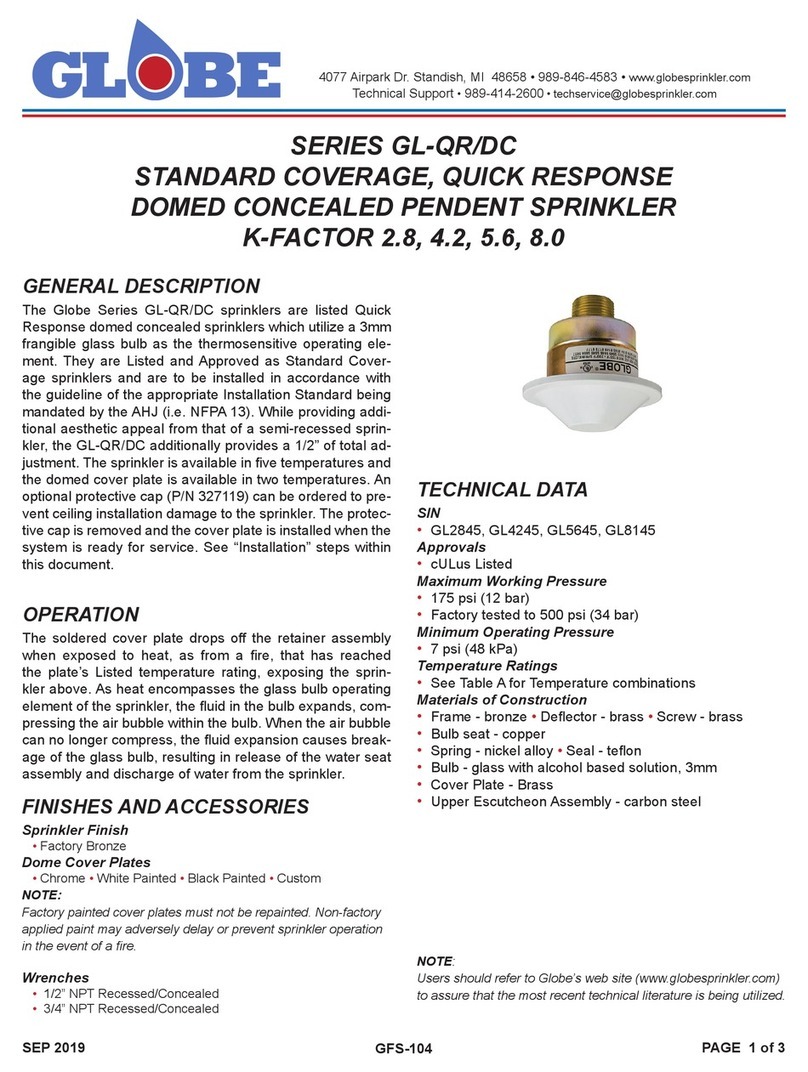

GENERAL DESCRIPTION

The Globe Series GL-QR/INCH/ECLH sprinkler is a Listed

Quick Response concealed sprinkler which utilizes a 3mm

frangible glass bulb as the thermosensitive operating ele-

ment. It is Listed and Approved as an Extended Coverage

sprinkler for Light Hazard Occupancies for a maximum cov-

erage area of 400 sq. ft. and is to be installed in accordance

with the guidelines of the appropriate Installation Standard

being mandated by the AHJ (i.e. NFPA 13). While providing

the optimal aesthetic appeal with the low prole at cover

plate, the GL-QR/INCH/ECLH additionally provides the larg-

est vertical adjustment in the industry of a nominal 1”. This

nominal 1” adjustment allows for previously unrecognized

installation exibility resulting in a clean and tight nal “t” to

the ceiling. The sprinkler is available in three temperatures

and the cover plate is available in two temperatures. The

nominal K-Factor is 5.6 (80,6) and the threads are 1/2” npt. TECHNICAL DATA

SIN

• GL5603

Approvals

• cULus - Light Hazard

Maximum Working Pressure

• 175 psi (12 bar)

Minimum Operating Pressure

• See TABLE A

Minimum Spacing

• 8 ft. (2.4 m)

Temperature Rating

• See TABLE A

Materials of Construction

• Frame - bronze • Deector - brass •Screw - brass

•Bulb seat - copper

• Spring - nickel alloy • Seal - teon

• Bulb - glass with alcohol based solution, 3mm

• Cover Plate - brass

• Upper Escutcheon Assembly - carbon steel

SERIES GL-QR/INCH/ECLH EXTENDED COVERAGE, QUICK RESPONSE,

LIGHT HAZARD CONCEALED PENDENT SPRINKLERS K-FACTOR: 5.6

SERIES GL-QR/ECLH/INCH/ECLH EXTENDED COVERAGE, QUICK RE-

SPONSE, LIGHT HAZARD CONCEALED PENDENT SPRINKLERS K-FAC-

TOR: 5.6

GFS-210 GFS-210

FINISHES AND ACCESSORIES

Sprinkler Finish

• Factory Bronze

Cover Plates

• Chrome •White Painted •Black Painted • Custom

Caution:

Factory painted cover plates must not be repainted. Non-factory

applied paint may adversely delay or prevent sprinkler operation

in the event of a re.

Wrench

• 1/2” NPT 1” Adjustable Concealed P/N 332765

OPERATION

The soldered cover plate drops o the retainer assembly

when exposed to heat, as from a re, that has reached the

plate’s Listed temperature rating exposing the sprinkler

above. Upon the releasing of the cover plate, the deector,

which is connected to two guide pins, drops down below

the ceiling into its intended position. As heat encompasses

the glass bulb operating element of the sprinkler, the uid

in the bulb expands, compressing the air bubble within the

bulb. When the air bubble can no longer compress, the uid

expansion causes breakage of the glass bulb, resulting in

release of the water seat assembly, and discharge of water

from the sprinkler.