Page 7

Safeguards & Safety Instructions

When using electrical appliances, basic safety precautions should always be followed. Follow all safeguards and

safety instructions including, but not limited to, the following:

TO AVOID SERIOUS PERSONAL INJURY: Do not attempt to fry with this unit. This unit is not a fryer.

During and after operation pasta cooker reaches very high temperatures. The

water, water pot, and all surfaces will be EXTREMELY HOT. Take extreme

caution when operating. Let water and pasta cooker cool before handling water or

equipment.

• DO NOT operate electric pasta cooker before reading the instruction manual.

• DO NOT touch pasta cooker or water during or after cooking. All parts become EXTREMELY HOT.

• ALWAYS disconnect or unplug electrical power before cleaning, servicing or adjusting parts or attachments.

• NEVER bypass, alter, modify or attach unauthorized parts to equipment. Doing so can create hazards

and will void warranty.

• NEVER operate unit with a damaged power cord or plug.

• NEVER leave pasta cooker on overnight or for prolonged periods of non-use.

• NEVER use pasta cooker as a heating source for your kitchen, space, or room.

• ALWAYS keep hands, hair and clothing away from heating elements.

• NEVER handle unit, pan and water during and directly after use. ALWAYS allow unit and water to cool

completely before handling equipment.

• DO NOT overload pasta cooker with water or food product. Water will splatter causing serious injuries

and burns.

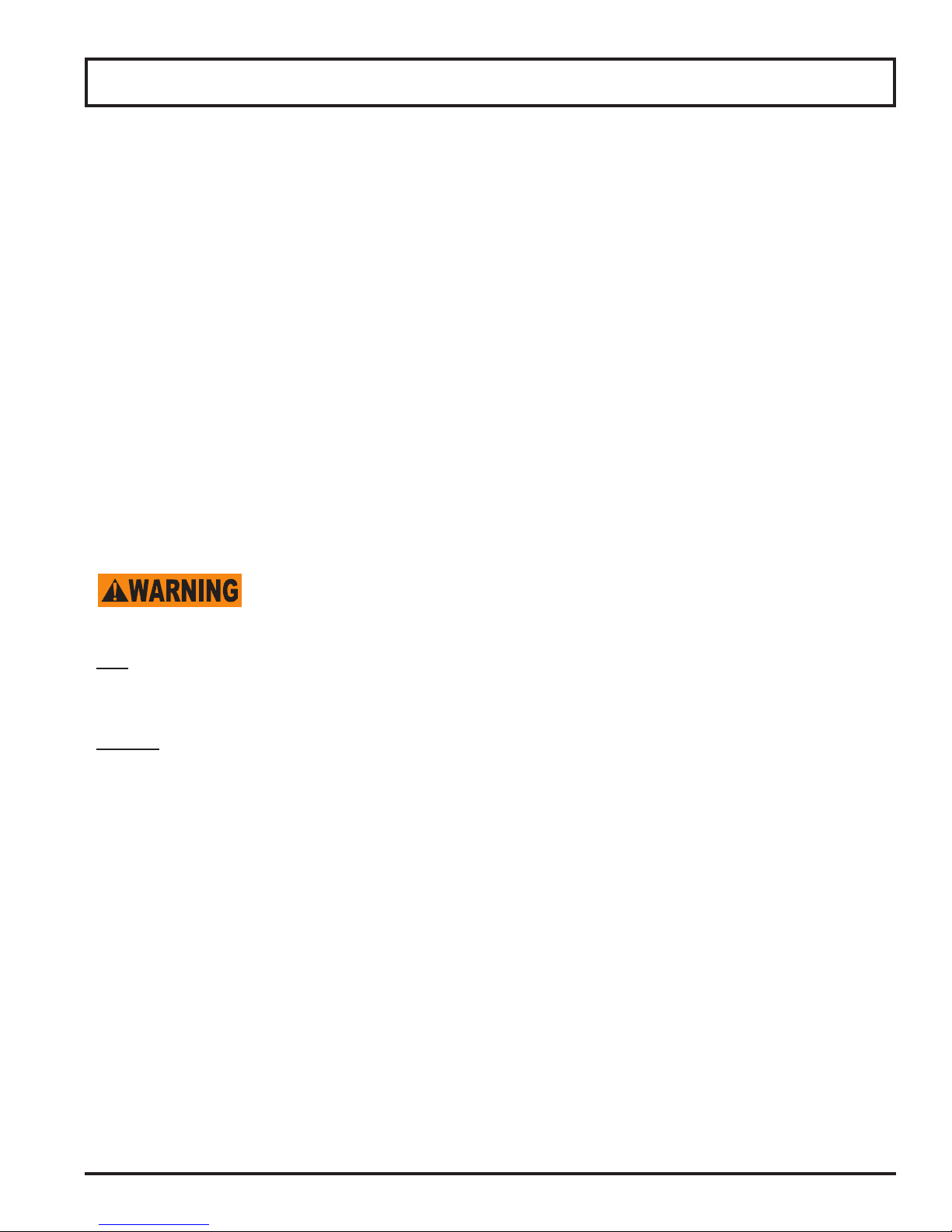

• DO NOT pull/yank on cord to disconnect. Turn off all controls, then gently remove plug

from wall outlet.

• Before handling and cleaning – Switch “Off” the power and disconnect from the main power.

Unit must be unplugged and cool to touch. Allow time for water to cool as well. Unit will be too

hot to handle immediately after use.

When using electrical appliances, basic safety precautions must always be

followed. DO NOT operate electric pasta cooker if unit appears damaged or

malfunctions in any manner. Call Globe Customer Service for assistance.

• Close supervision is necessary when pasta cooker is being used. Operator must be properly trained

on all operational and safety procedures, especially when using near others.

• To protect against electrical shock, do not immerse cord, plugs or appliance in water, liquid or dishmachine.

• Unplug unit when not in use and before cleaning. Allow unit and water to cool before moving or cleaning.

• Use of accessories or cooking pans that are not recommended by the manufacturer, can cause

re and/or injury.

• DO NOT use outdoors. For indoor use only.

• Do not allow power cord to hang over edge of table or counter, or to touch hot surfaces.

• Do not place pasta cooker in, on or near open ames, electric burners, heated ovens or other high

temperature equipment or surroundings.

• Do not use pasta cooker for anything other than boiling water for cooking. Use with provided basket(s) and

supervision.

• Do NOT pull/yank on cord to disconnect.

• Globe takes care to make sure that all products are safe. Steel cutting procedures used to manufacture

these items result in sharp edges. Take care when in contact with pasta cooker.

• Continually observe and maintain water level in boiling pan. Water level will decrease with each boil.

• ALWAYS BE PREPARED in case of a re, make sure to have the correctly rated re extinguisher nearby.

• DO NOT immerse pasta cooker in water, as this will cause permanent damage to unit.

The pasta cooker does not contain any user-serviceable parts. Globe dealers or recommended qualied technicians

must carry out repairs. Do not remove components or service panels on this product.